Chile Mining Truck Camera System and Fleet Tracking Management

Chile Mining Truck Camera System

As a major global mineral resource country, Chile's mining truck fleets face complex management challenges. Mining truck camera systems and fleet tracking management systems are becoming key tools to improve efficiency and safety.

Challenges in Chilean Mining Truck Management

Large Chilean mining companies operate hundreds to thousands of heavy-duty mining trucks, mainly distributed in complex mining areas such as the Atacama Desert. These areas face multiple management challenges:

1. Complex Communication and Positioning Environment

- The terrain includes deserts, mountains, and underground mines.

- Open-pit mines suffer from signal reflection, causing large positioning errors.

- Underground mines have almost no satellite signals, limited 4G/5G coverage, making real-time positioning difficult.

2. Diverse Fleet Types and Needs

- Fleets include transport trucks, excavators, loaders, etc.

- Different vehicles require different monitoring data; a single tracking system cannot meet all needs, necessitating multi-source data integration.

3. High Safety Pressure

- Poor road conditions, large vehicles, and driver fatigue increase risks.

- Roads have blind spots and falling rock hazards, requiring intelligent warnings and video recording to reduce accidents.

4. Maintenance and Investment Challenges

- High failure rates of mining equipment and high maintenance costs.

- Some companies question the ROI of intelligent systems, affecting adoption of new technologies.

Mining Truck Camera + Fleet Management System

Chilean mining companies are deploying intelligent management systems to achieve:

- Real-time visual monitoring: Track vehicle location, trajectory, and driver behavior through cameras and positioning systems.

- Intelligent warning and protection: Automatically detect overspeeding, fatigue driving, and other hazards, issuing timely alerts.

- Efficient scheduling optimization: Dynamically adjust routes, reduce empty trips, and improve efficiency.

- Data-driven maintenance: Collect operational data to support predictive maintenance and informed decision-making.

- Safety and compliance management: Video and location records support incident investigation and regulatory compliance.

YUWEI Mining Truck Camera System

YUWEI offers intelligent management systems tailored for Chilean mining areas, with applications in China, Australia, Chile, and other countries, adapting to complex environments.

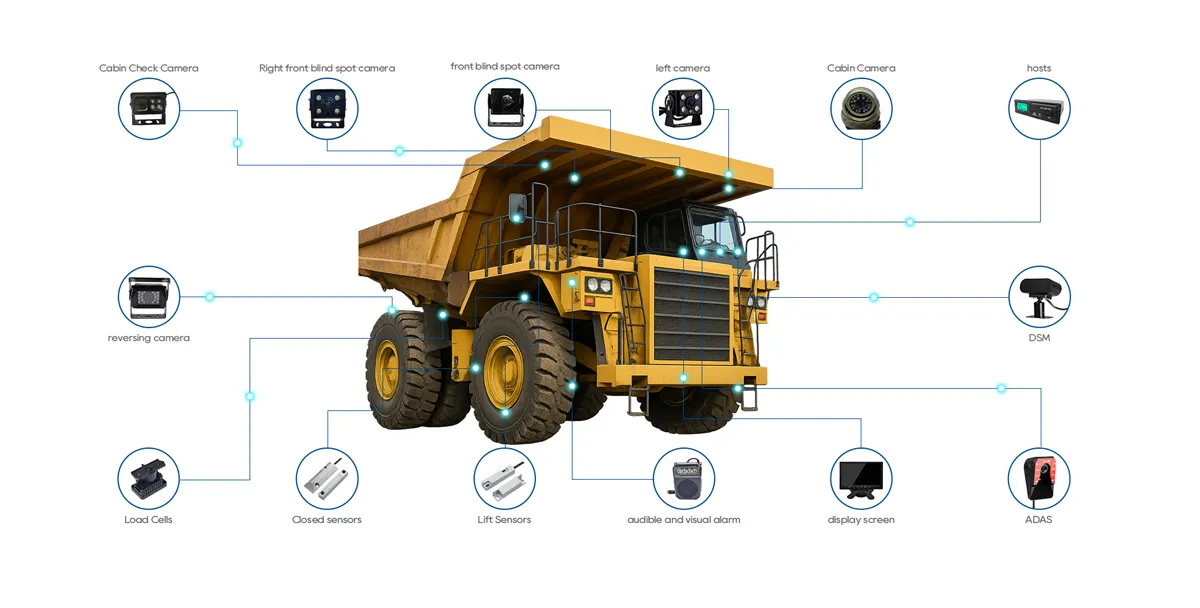

1. Core Hardware Components

(1) High-definition Cameras

- 1080P panoramic camera: Eliminates blind spots in mining trucks.

- Reversing/360° camera: Assists with low-speed maneuvers and reversing.

- ADAS front/side cameras: Monitor vehicle distance and lane deviation.

- DMS cabin camera: Detects fatigue and distracted driving.

- BSD blind spot cameras: Monitor high-risk blind spots.

- DSM specialized cameras: Adapt to nighttime environments and detect driver status.

(2) MDVR Video Recorder

- Supports multiple cameras with centralized video storage.

- Industrial-grade design, high-temperature resistant, shockproof.

- Event-triggered recording and real-time upload.

(3) Positioning and Communication

- GPS/BDS dual-mode positioning: Suitable for open-pit and some underground areas.

- Optional UWB positioning: Supplements underground signals.

- 4G/5G modules: Ensure data and video transmission.

(4) AI Intelligent Analysis

- Integrates ADAS, DSM, and BSD algorithms.

- Detects dangerous behaviors and issues early warnings.

- Supports custom algorithms to meet specific requirements.

Key Functional Highlights

(1) Real-time Positioning and Monitoring

- GPS/BDS positioning combined with video for real-time vehicle status.

- Supports trajectory playback and video linkage.

(2) Intelligent Driving Assistance

- ADAS cameras detect hazards and provide early warnings.

- DMS monitors drivers, issuing alerts for fatigue or distraction.

(3) Blind Spot Monitoring

- BSD cameras monitor blind spots, alerting for pedestrians or obstacles.

- Dual in-cabin and external warnings reduce collisions.

(4) Efficient Scheduling Analysis

- Supports task allocation and route optimization to reduce empty trips.

- Provides KPI statistics on transport volume, energy consumption, etc.

(5) Remote and Mobile Management

- Multi-terminal access for real-time vehicle and alert monitoring.

- Multi-role permissions meet diverse operational needs.

(6) System Expansion and Integration

- Compatible with MES, EAM, and other platforms.

- Hardware upgradable, software iteratively improved.

YUWEI continues to provide safe, efficient, and intelligent mining truck management solutions, helping mining companies reduce costs, improve efficiency, and achieve sustainable development.

For more details on YUWEI mining truck camera and management systems, please contact the technical team or visit the official website for customized solutions.