Which AI Dash Cam is Best for Heavy Equipment?

Heavy Equipment Dash Cam

In scenarios such as mining, infrastructure construction, and port transportation, the safety and efficiency of heavy equipment fleets—like mining trucks, excavators, and concrete mixers—directly affect a company’s economic performance and personnel safety.

According to the International Construction Equipment Manufacturers Association (ICEMA) 2024 data, global heavy equipment fleets incur annual losses exceeding $4.5 billiondue to "blind-spot collisions," "fatigue driving," and "operational violations." Domestic research by a leading infrastructure company further revealed that 67% of fleet accidentsare directly linked to "non-compliant driver behavior" and "uncontrollable equipment status," with single-incident repair and downtime costs reaching 150,000 RMB.

Faced with these challenges, traditional dash cams’ "post-incident recording" approach is now completely inadequate—blurry nighttime footage, single-function recording, and fragile designs unable to withstand extreme conditions leave fleet managers trapped in a triple dilemma: unpredictable risks, unmonitored behavior, and low operational efficiency.

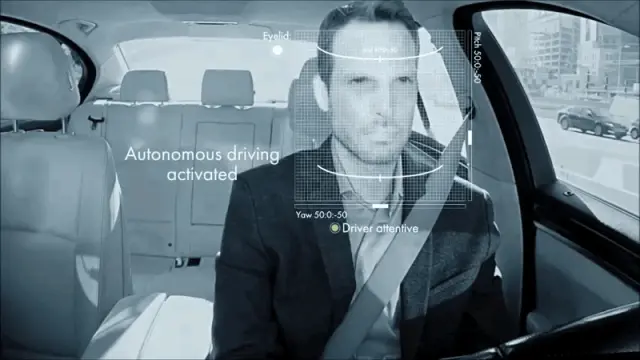

The solution lies in “AI dash cams and fleet tracking management for heavy equipment”: by leveraging multi-sensor fusion, AI proactive alerts, and real-time data tracking, a dash cam designed for heavy equipment should not only record incidents but also predict risks, optimize management, and serve as the fleet’s “second eyes” and “intelligent brain.”

Special Requirements for Heavy Equipment Fleets

Heavy equipment differs fundamentally from passenger vehicles in operational environment, asset value, and management complexity. Choosing the right dash cam requires clarity on three core needs:

1.1 Zero-Failure in Extreme Environments

Heavy equipment often operates in mining (-40°C), ports (85°C), or dusty construction sites, with vibrations exceeding 5g(vs. 1–2g for passenger cars). Ordinary dash cams with plastic casings, poorly soldered chips, and fog-prone lenses risk losing critical dataand leaving no evidence in case of accidents.

1.2 Strong Proactive Safety Intervention

With equipment valued at over 1 million RMB(e.g., imported mining trucks at 3 million+ RMB), a single operational mistake can cause equipment damage or chain accidents. Fleets need dash cams that provide 10-second advanced warnings, identifying fatigue, blind-spot pedestrians, overload, and deviations, with active intervention.

1.3 Data-Driven Fleet Management

Large fleets may manage 50+ vehicles across multiple sites, with varying vehicle types and high driver turnover. Traditional manual inspections and post-incident video review cannot satisfy the need for real-time monitoring, risk analytics, and efficiency optimization.

AI Dash Cam for Heavy Equipment Fleets

To address these pain points, a dash cam suitable for heavy fleets must combine:

① Extreme environment durability

② Multi-modal AI alert capability

③ Advanced data management

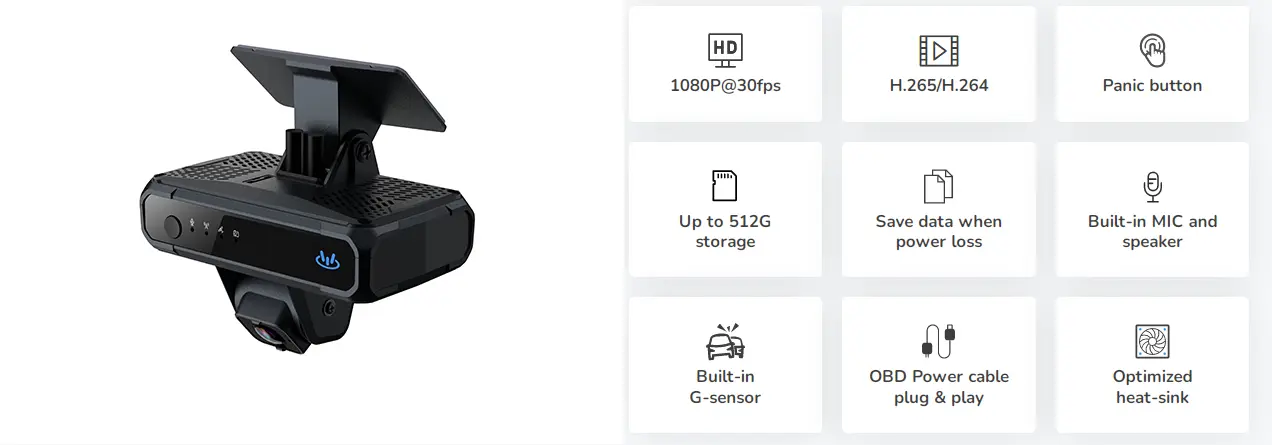

The YUWEI V8N Smart Dash Cam, with dual-camera fusion, five AI algorithms, and multi-scenario data management, precisely meets these requirements and has become the 2025 industry benchmark.

2.1 Rock-Solid Performance in Extreme Environments

Heavy equipment demands military-grade hardware reliability. YUWEI V8N solves typical dash cam issues with:

① Wide-temperature operation:-40°C to 85°C support, embedded Linux optimization, and heated defrost lens (-30°C auto-start). Stable 24/7 recording in extreme conditions.

② Shock and vibration resistance:High-strength engineering plastic + reinforced screws, passing rigorous vibration tests for heavy equipment.

③ Dust and water protection:IP65-rated, industrial-grade protection, ensuring long-term clear lenses and uninterrupted recording.

2.2 Multi-Modal AI Alerts: From Passive Recording to Active Intervention

90% of heavy equipment accidents can be avoided with advanced warnings. YUWEI V8N integrates ADAS + DMS + BSD + Aggressive Driving Detection, creating a full human-vehicle-road risk control system:

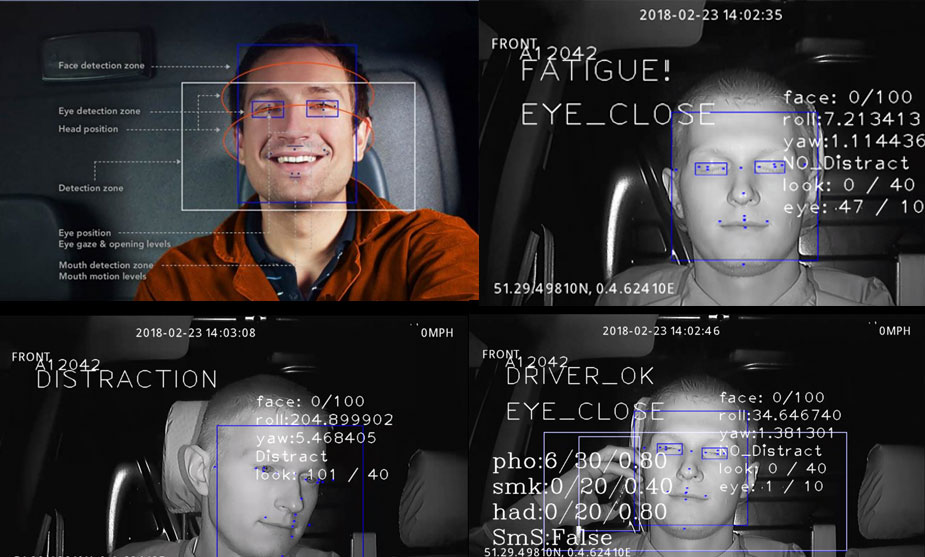

a. Driver Behavior “Second-Level Alerts” (DMS + Face Recognition):

Infrared camera monitors fatigue, distraction, and safety violations, triggering sound-light alerts and platform notifications. Case study: fatigue-related accidents dropped 79%, and violation response efficiency increased 60%.

b. Driving Risk “Active Defense” (ADAS + BSD):

Front starlight camera detects lane departure, distance monitoring, forward collisions, and pedestrian collisions. Optional BSD covers blind spots, forming a 360° electronic fence. Port fleet use resulted in zero blind-spot collisions.

c. Aggressive Driving Detection:

Identifies rapid acceleration, braking, or sharp turns to prevent equipment damage. Mining fleet use reduced repair costs by 22%.

2.3 One-Stop Fleet Management

YUWEI V8N’s smart management platform + mobile appintegrates driver, vehicle, behavior, and equipment data for remote monitoring, statistical analysis, and optimized decision-making:

① Real-time positioning and track replay:Updates every 5 seconds (±2m accuracy), reducing empty mileage by 28%and saving 150,000 RMB/monthin fuel.

② Multi-dimensional reports:Auto-generates violation stats, load analysis, and fuel alerts for precise management and cost savings.

③ Remote diagnostics and data export:USB export and CAN-bus fault alerts reduce unplanned downtime by 40%.

YUWEI V8N Key Configurations

① Dual-camera + expansion:Up to 4-channel recording covering driver, vehicle, and road.

② Low-power mode:2mA/5mA operation for extended standby.

③ Reliable storage:Dual TF cards + patented DXR Stream format, supporting 30 days of high-intensity use without file loss.

④ Strong compatibility:Compact design, optional external monitor, flexible installation without blocking the driver’s view.

Case Study: Southwest Infrastructure Group

After deploying 60 heavy equipment units(25 mining trucks, 20 excavators, 15 concrete mixers):

① Safety incidents:Monthly accidents reduced from 3.8 to 0.2, saving 920,000 RMB.

② Management efficiency:Manual inspection time reduced from 18h/week to 1.5h, violation handling up 65%.

③ Cost optimization:Fuel expenses down 20%, maintenance costs down 25%.

④ Compliance:100% complete incident video, insurance claims processed in 1 hour vs. 3 days.

For heavy equipment fleets, AI dash cams and fleet trackinghave evolved from optional tools to core competitiveness.YUWEI V8N, with extreme durability + AI alerts + deep data management, resolves traditional dash cam limitations and enables zero-accident safety and high operational efficiency.

If your fleet struggles with blind-spot accidents, fatigue driving, or chaotic management, YUWEI V8Nis the smart guardian your fleet deserves.

Email:hello@yuweitek.com