AI Forklift Camera & Safety Systems for Trucks & Warehouses

AI Forklift Camera & Safety Systems

With the upgrade of industrial automation, forklift safety accidents cause over 100,000 injuries worldwide every year (OSHA data), resulting in direct economic losses of billions of US dollars. YUWEI forklift camera systems can be connected wirelessly or via wires, consisting of components such as waterproof monitors, cameras, transceivers, and battery boxes. Equipped with a 9-inch LCD display, 120-degree viewing angle, and night vision function, they eliminate blind spots in front, behind, and on the sides of forklifts, enhancing operational safety and accuracy. For related products, you can contact this Chinese manufacturer via hello@yuweitek.com.

hnweb_

Pain Points of Traditional Forklift Management

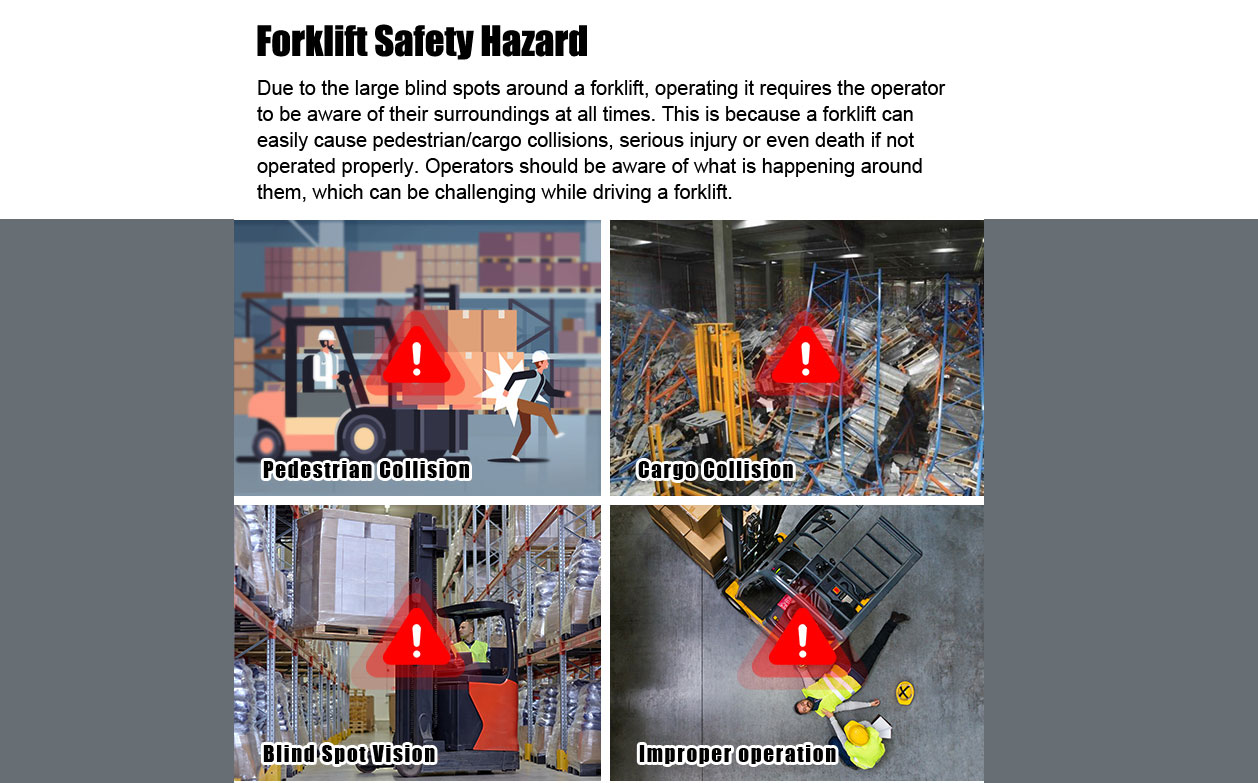

1. Blind Spot Hazards

① 80% of forklift reversing accidents stem from visual blind spots (NIOSH research).

② Shelf obstruction increases cargo damage rate by 23%.

2. Frequent Human Errors

① Misoperations caused by fatigue driving account for 45%.

② The training cycle for new drivers is more than 3 months.

3. High Supervision Costs

① Post-accident accountability relies on manual video review, with low efficiency.

② Compliance inspections require additional labor costs.

Solution of YUWEI AI Forklift Monitoring System

1.Hardware Architecture

· Multi-dimensional visual perception

① Fork view camera: Captures real-time fork operation details (accuracy 0.1 meters).

② 360° panoramic view: Eliminates detection blind spots within a 5-meter radius.

③ Rear collision avoidance camera: Automatically switches viewing angles to reduce scratches.

· Environmental perception layer

① LiDAR: Detects dynamic obstacles within a 15-meter radius.

② High-definition GPS module: Trajectory tracking error < 2cm.

2.Intelligent Software System

· AI prediction engine

① Pedestrian recognition accuracy > 98% (supports night mode).

② Vehicle spacing warning (minimum safe distance customizable).

· Driver Monitoring System (DMS)

① Eye closure/distraction detection response time < 0.5 seconds.

② Fatigue index graded warning mechanism.

Core Function Comparison Table

Function Module | YUWEI System | Traditional Solution |

Video Recording | 1080P@30fps wireless transmission | 720P local storage |

Real-time Alert | Multi-level audio-visual alert + APP push | No active intervention |

Data Retention | Cloud platform 90-day historical traceability | Local storage prone to loss |

Expansion Capability | Supports RFID/weighing sensor integration | Single-function closed system |

Deployment Benefit Analysis

1.Safety Dimension

① Collision accidents reduced by 67% after implementation (based on measured data from an auto parts warehouse).

② Risk coefficient in pedestrian traffic areas decreased by 82%.

2.Efficiency Improvement

① Cargo turnover efficiency increased by 22% (reducing downtime caused by accidents).

② New employee training cycle shortened to 14 days.

3.Return on Investment

① Average hardware cost recovery in 14 months.

② Insurance rates can be reduced by up to 35%.

Typical Application Scenarios

1. High-Rack Warehouses

① Mast camera monitors shelf stability in real time.

② Load deviation warning prevents tipping accidents.

2. Cold Chain Warehousing

① Anti-fog lens adapts to extreme temperatures of -30℃~60℃.

② IP68 waterproof rating ensures operation in humid environments.

3. Mixed Vehicle Type Fields

① Automatically identifies forklifts/AGVs/manual vehicles.

② Dynamically adjusts safety protection strategies.

Why Choose YUWEI?

① Localization adaptation: Complies with strict European and American industrial vehicle safety standards; supports Beidou/GPS dual-mode positioning.

② Flexible deployment: Supports multiple networking methods including 4G/5G/WiFi; private deployment ensures data security.

③ Full-lifecycle service: Provides quality assurance and remote OTA upgrades; customized development meets special scenario needs.