Best AI Dash Cam for Construction Trucks

Construction Truck AI Dash Camera

With the rapid development of global infrastructure and mining, construction trucks (including dump trucks, mining trucks, concrete mixers, etc.) serve as the backbone of material transportation, facing the dual challenges of high operational intensity and high-risk scenarios. According to the China Construction Machinery Industry Association 2024 data, there are over 12 million construction trucks in China, covering more than 30 billion kilometers annually. However, due to large blind spots and complex working conditions (dust in mining areas, nighttime construction, heavy-load uphill driving), their accident rate is 47% higher than ordinary commercial vehicles.

hnweb_

How can accidents be reduced and efficiency improved? AI dash cams for construction trucks have become a necessity, and the YUWEI V8N intelligent recorder is an AI solution optimized for these complex scenarios.

“Special Requirements” of Construction Trucks

Construction trucks operate in complex environments, so dash cams must meet three key requirements: environmental adaptability, risk prediction, and management compatibility.

1.1 Multiple Operational Challenges: High Temperature, Dust, and Vibration

Construction trucks mainly operate in mines, construction sites, and ports under harsh conditions:

① Dust concentration exceeds 500μg/m³ (compared to 100μg/m³ in cities).

② Potholes cause vibration frequencies ≥10Hz.

③ Port salt spray accelerates equipment aging.

Operational risks are high:

① Hydraulic failures in dump truck lifting mechanisms occur in 32% of cases.

② Mixer drums may harden if spun too fast.

③ Heavy-load trucks require 2.5 times longer braking distance.

Drivers work 8–10 hours daily (some over 12 hours), with fatigue driving at 58% and distraction-related accidents (phone use, blind spot oversight) accounting for 63%.

1.2 Limitations of Traditional Dash Cams

Conventional dash cams struggle in construction environments:

① Protection often only IP54 (insufficient against washdowns or heavy rain).

② Passive recording only (no pre-collision warning).

③ Data redundancy (over 20GB/day, hard to extract key metrics).

A 2023 survey of a construction company found that with traditional dash cams, only 12% of accidents could assign clear responsibility; 78% resulted in secondary injuries due to lack of warnings (e.g., falling cargo).

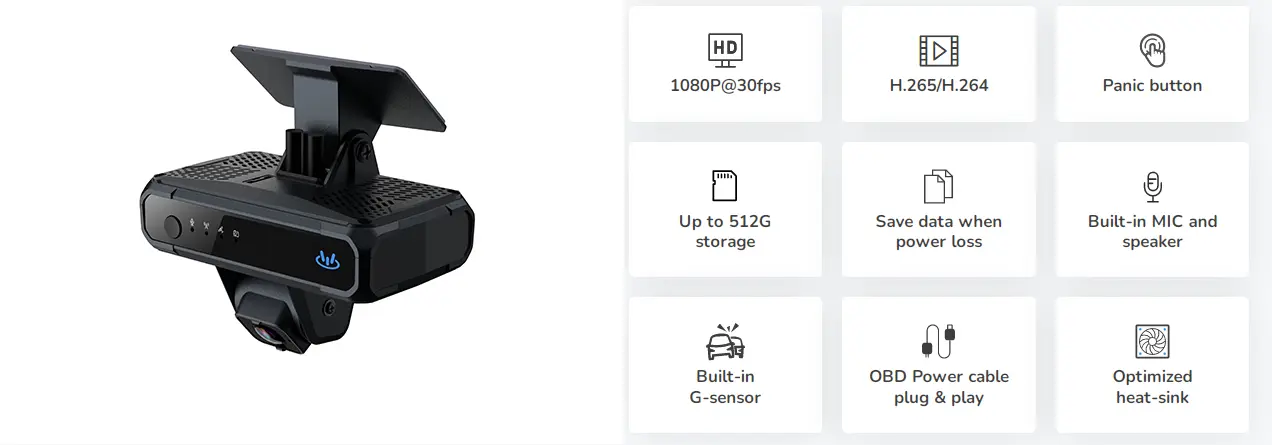

YUWEI V8N Overview

The V8N integrates 4G + AI + multi-cameratechnology, designed for high-intensity, high-risk construction truck scenarios, offering three main advantages:

2.1 Durable Construction: Engineered for Tough Environments

① High-strength engineering plastic body with elastic silicone shock-absorbing mount.

② Absorbs 20–2000Hz vibrations (tested on mine gravel roads, displacement ≤0.1mm).

③ Dual TF card expansion (up to 2TB per card) + proprietary DXR Stream format ensures stability in humid, dusty environments (tested 100 hours in mining dust without failure).

④ Compact installation, unobstructed view, suitable for tight spaces in dump trucks and mining trucks.

2.2 Full-Scenario AI Perception

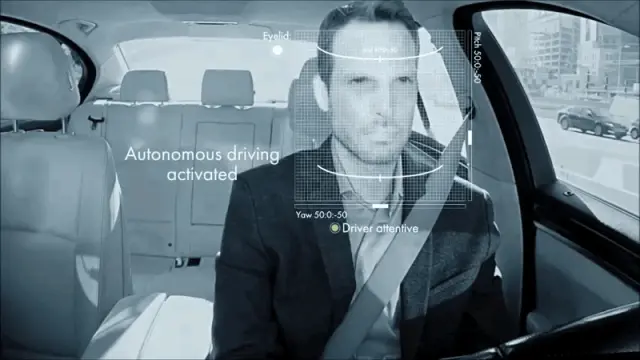

① Driver Monitoring System (DMS):IR-CUT infrared internal camera (HFOV 152° / DFOV 180°, 720P) detects fatigue (eyes closed >2s) and distraction (phone, smoking, inattentive), with voice alerts.

② ADAS + BSD (Vehicle & Road Safety):Front starlight-level camera (HFOV 106° / DFOV 139°, 1080P) supports lane departure warning, distance monitoring, and forward collision warning. Optional BSD camera monitors blind spots for pedestrians and non-motor vehicles, reducing “sudden appearance” accidents.

③ Aggressive Driving Detection:Accelerometer + AI detects harsh acceleration, braking, and sharp turns, issuing voice reminders to drive smoothly.

④ System Integration:CAN bus collects OBD data (engine RPM, brake pressure), combined with GNSS 4G positioning, correlating driving behavior, vehicle status, and location to identify high-risk events (e.g., hard braking with overload + high brake temperature).

2.3 Data Closed Loop

① Real-Time Monitoring & Playback:4G connectivity allows app access to vehicle location, driver status, and live video. Historical video is classified and stored (dual 2TB TF cards) for accountability and training.

② Custom Alerts:App-configurable thresholds (e.g., dump truck bed angle >60°, mixer drum speed >120 RPM) trigger audible/visual alarms and platform upload for early intervention.

③ Cost Reduction & Efficiency:Automatically generates fatigue reports and accident responsibility reports; combined with ADAS data, driving behavior is optimized (e.g., reducing harsh braking lowers fuel consumption by 15%). A construction company reported 18% annual insurance reduction and 40% decrease in accident/repair costs.

Real-World Case

A large coal mine in Shanxi deployed 50 V8N units in early 2024. Within 3 months:

① Fatigue/distraction accidents dropped from 4 per month to 0.

② Blind spot collisions reduced by 85% (loss per incident dropped from ¥250,000 to ¥30,000).

③ Inspection time for managers reduced by 50%, and accident accountability determination dropped from 3 days to 2 hours.

④ Annual comprehensive costs decreased by over ¥500,000 (insurance down 20%, cargo loss down 70%).

Choosing an AI dash cam for construction trucks should focus on solving real-world problems. The YUWEI V8N, with its 4G + multi-camera + full-scenario AI, delivers durable hardware, precise perception, and a complete data loop—transforming a “recording tool” into a “safety brain.” Installing a V8N on construction trucks improves both safety and operational efficiency.

Email:hello@yuweitek.com