Best Dash Cam with AI for Construction Fleet Management

Construction Fleet Management AI Dash Camera

Southeast Asia’s “infrastructure boom” is reshaping the regional economic landscape. From the Jakarta-Bandung high-speed railway testing in Indonesia, the accelerated rollout of Thailand’s Eastern Economic Corridor, to the completion of Vietnam’s North-South Expressway western line, infrastructure projects are expanding rapidly. According to the World Bank 2024 data, annual infrastructure investment in six Southeast Asian countries (Indonesia, Thailand, Vietnam, Malaysia, the Philippines, Singapore) exceeds $300 billion, with over 60% allocated to construction projects.

Supporting these “mega-projects” are construction fleets with over 500,000 active vehicles daily—from earthmoving trucks and concrete mixers to aerial work platforms. These fleets are not only the “lifeblood” of projects but also major pain points in safety and cost management.

Challenges in Commercial Fleet Management

1. Earthmoving Vehicle Fleets (35%)

Mainly dump trucks and excavator carriers, commonly used in mining and roadbed construction. In Indonesia and Malaysia, individual projects can involve 200–500 vehicles.

Pain Points:

① High idle rates (average 30%)

② Poor location tracking at remote sites causing scheduling delays

③ Frequent nighttime accidents (Indonesian data shows nighttime accident rates are 42% higher than daytime)

2. Concrete Mixer Fleets (28%)

Including mixers and pump trucks, essential for building and bridge projects. Thailand and Vietnam projects require 24-hour shifts.

Pain Points:

① Strict concrete setting time limits (strength drops 15% if delayed by 1 hour), difficult to monitor transport duration with traditional devices

② Driver misconduct, such as unauthorized water addition (Philippines survey shows 18% of mixers involved in material skimming)

3. Heavy Equipment Transport Fleets (22%)

Transporting cranes, tunnel boring machines, and other large equipment for subways, ports, and other infrastructure. In Singapore, moving a single tunnel boring machine requires 6–8 specialized trailers.

Pain Points:

① High-value equipment (over $10 million per unit) with significant collision risks

② Cross-border transport compliance is challenging (e.g., Laos-China railway requires 72-hour prior approval for overweight transport)

4. Support Vehicle Fleets (15%)

Includes water trucks, sweepers, and other vehicles responsible for site maintenance. In Malaysia MRT projects, these fleets operate over 12 hours daily.

Pain Points:

① Widely dispersed work areas (e.g., forest roads in Johor), making vehicle tracking difficult

② Slow emergency dispatch and poor nearest-vehicle matching

Southeast Asian construction fleets face common management challenges:

① Safety monitoring difficulty:accident rates 2.3x higher than urban traffic

② Efficiency improvement difficulty:average waiting/idle time 28%

③ Cost control difficulty:fuel and maintenance exceed budgets by 15%

Traditional dash cams only provide post-event footage and are inadequate for modern intelligent, precise fleet management.

Why Southeast Asian Construction Fleets Need AI Dash Cams

Unlike traditional “passive recording” devices, AI dash camsintegrate visual recognition, ADAS (Advanced Driver Assistance Systems), and IoT technologies, enabling a shift from “recording” to “analysis + intervention.” This aligns perfectly with the complex management needs of construction fleets.

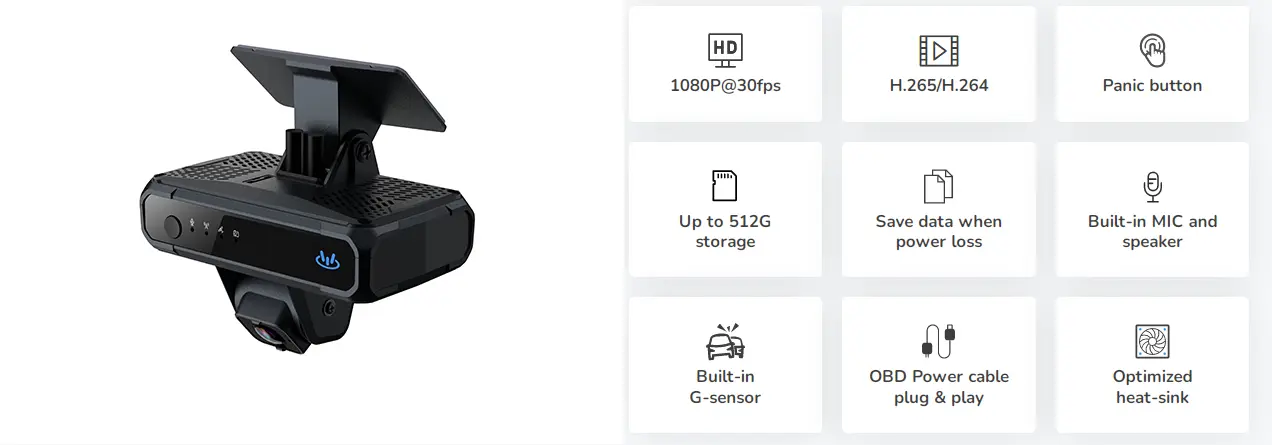

For example, China’s YUWEI V8N Smart Dash Camoffers customized features for Southeast Asian construction scenarios, becoming the preferred choice for leading regional engineering companies.

1. Safety Management

Construction fleet accidents are costly. Indonesian Industrial Safety Association data shows that a single major accident (serious injury or equipment damage) can delay a project by 7 days, with direct losses exceeding $50,000.

YUWEI V8N features include:

① External Safety: ADAS + BSD Blind Spot Monitoring

Built-in ADAS features (Lane Departure Warning LDW, Headway Monitoring HMW, Forward Collision Warning FCW, Pedestrian Collision Warning PCW) paired with optional BSD blind-spot cameras detect pedestrians and vehicles in blind zones. Millimeter-wave radar and camera fusion provides a 2-second early warning. In an Indonesian coal mine, blind spot monitoring reduced truck-motorcycle collisions by 38%.

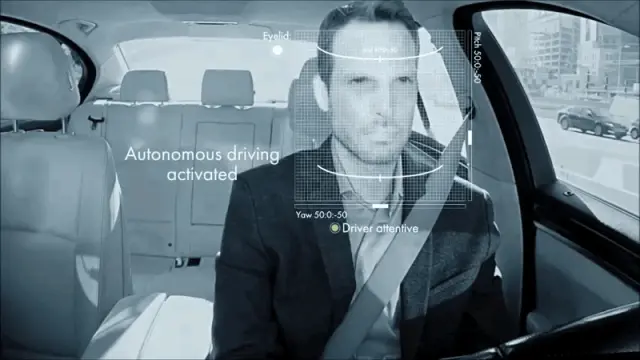

② Internal Safety: DMS + Facial Recognition

The 2MP IR-CUT internal camera supports 720P recording, monitoring driver fatigue (yawning, eyes closed >2 sec), distraction (phone use), and seat belt compliance. Alerts are sent via in-cab signals and platform notifications. At a Philippine port expansion, accidents dropped 41% within three months.

③ Extreme Environment Adaptation

Compact design avoids blocking driver view and operates in -30°C to 70°C, ensuring reliable performance in rain, dust, and high temperatures (up to 35°C+).

2. Efficiency Improvement

Fleet efficiency directly affects project progress and costs. V8N’s 4G + GNSS + multi-channel video setup provides real-time, multidimensional decision support:

① Real-time location and route playback

GNSS module (GPS + BDS + GLONASS) maintains >95% positioning success even in tunnels or mountainous regions. 4G LTE ensures live data upload. In a Malaysian railway project, route replay revealed 30% of vehicles detouring for fuel; route adjustment reduced monthly fuel costs by 12%.

② Precise transport timing monitoring

Supports “load-transport-unload” thresholds (e.g., concrete ≤45 minutes). Automatic alerts allow dispatchers to reroute or swap vehicles, reducing material waste (concrete loss dropped from 8% to 3% in the Philippines).

③ Multi-channel video storage and retrieval

Up to 4-channel recording (main 2 + optional 2), dual TF cards (up to 2TB each) ensure storage reliability. Key video can be retrieved immediately, reducing insurance claim processing from 7 days to 2 days.

3. Compliance and Cost Control

Southeast Asian regulations are increasingly strict:

① Indonesia requires electronic monitoring for transport vehicles

② Thailand fines late concrete deliveries up to 500,000 THB (~$10,000)

③ Vietnam mandates high-value third-party insurance

V8N’s compliance features help companies meet regulations effortlessly:

① Automatic electronic log generationfrom CAN bus data (driving time, mileage, OBD faults) prevents fines from manual errors

② Multilingual interface(Indonesian, Thai, Vietnamese, etc.) adapts to local drivers

③ Low-cost, efficient operationwith ultra-low power modes (2mA/5mA) and expandable cameras for rear or blind-spot monitoring

Why YUWEI V8N?

Southeast Asian construction companies prefer YUWEI V8N for three core advantages:

1. Deep Southeast Asia adaptation: dual-camera + AI design

① Front starlight HD camera + rear IR-CUT internal camera

② Covers external hazards and internal driver behavior

③ Perfect for earthmoving, mixer, and heavy equipment scenarios

2. High cost-performance full-chain data management

① 4G + Wi-Fi dual communication

② Dual TF cards (up to 4TB), multi-channel recording (4x720P)

③ Optional BSD cameras upgrade without replacing the main unit

3. Full lifecycle localized ecosystem support

① Hardware + SaaS fleet management platform

② Integration with ERP and project management software for seamless “device-data-management” collaboration

China’s YUWEI V8N Smart Dash Cam, with its dual-camera AI + full-chain data + localized adaptation, is rapidly becoming the top choice for Southeast Asian construction fleet tracking and management.

For more information, contact: hello@yuweitek.com