Concrete Mixer GPS Tracking

Concrete Mixer fleet GPS Tracking Management

YUWEI (China)introduces the Concrete Mixer GPS Tracking System, seamlessly integrating GPS positioning technology, AI visual recognition, and big data analyticsto deliver a 24/7, end-to-end digital fleet management solution.

Key Features

1. Precise Positioning & Real-Time Tracking

① Dual-Mode Navigation: Supports GPS + BeiDou dual-mode satellite positioningwith ≤5m accuracy, transmitting vehicle location, speed, and driving routes in real time.

② Dynamic Visualized Dispatching: Cloud-based mapping displays fleet distribution, intelligently plans optimal routes, and reduces idle driving and traffic delays.

③ Historical Route Playback: Retrieve trajectories for any time period to assist in accident analysis, liability determination, and compliance audits.

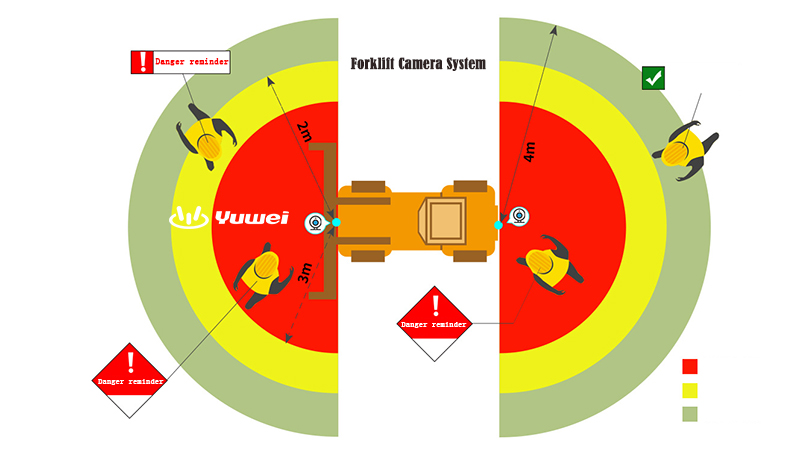

2. ADAS Active Safety Protection

① GPS + Sensor Linked Alerts: Combines positioning data with safety features such as Forward Collision Warning (FCW)and Blind Spot Detection (BSD), issuing alerts 1.5 seconds in advance.

② Geo-Fencing for Risk Zones: Set up virtual fences around sensitive areas (construction sites, schools, etc.); system triggers alarms and notifies management when vehicles overspeed or cross boundaries.

3. Comprehensive Video Monitoring

① GPS-Linked Evidence Collection: During sudden braking, lane deviation, or other risky behaviors, the system automatically tags GPS location with video footage for precise incident tracking.

② Remote Monitoring & Command: Identify abnormal vehicles via GPS, and allow managers to remotely access onboard cameras to guide drivers in real time.

4. Intelligent Data Analytics Platform

① Driver Behavior Profiling: Combines GPS speed data with DSM (Driver Status Monitoring) to detect fatigue and distraction, generating safety scores for drivers.

② Fuel Consumption Anomaly Alerts: Correlates mileage with fuel data to detect theft, idling, or abnormal consumption.

③ Electronic Fence Management: Automatically records loading/unloading time and location, preventing unauthorized dumping or route deviations.

Typical Application Scenarios

1. Construction Fleet Dispatching: A large infrastructure project improved vehicle utilization by 35% and reduced delivery time by 20% using YUWEI’s system.

2. Safe Driving Management: A concrete plant reduced fatigue driving incidents by 70% after integrating GPS + DSM, achieving its lowest accident rate ever.

3. Theft Prevention & Traceability: A Shenzhen logistics company successfully recovered over ¥100,000 worth of concrete material losses using GPS playback and video monitoring.

Technical Advantages & Industry Recognition

1. Hardware Reliability: Vehicle terminals are IP67-rated for water and dust resistance, operate from -40°C to 85°C, with 99.9% GPS stability.

2. High-Precision Positioning: Enhanced by BeiDou-3 satellites, ensuring accurate tracking even in tunnels, elevated roads, and complex environments.

3. Global Service Network: Deployed in Southeast Asia, Africa, and other overseas markets, supporting intelligent upgrades for Belt and Road projects.

The Concrete Mixer GPS Tracking Systemis not only a technological innovation but also a rethinking of project management strategies. Guided by the mission “Making every trip safer and more efficient,”YUWEI continues to drive the industry toward smarter and more refined operations.

Email:hello@yuweitek.com