Warehouse Forklift Telematics & GPS Tracking Management

YUWEI’s AI-Powered Forklift Telematics Solutions

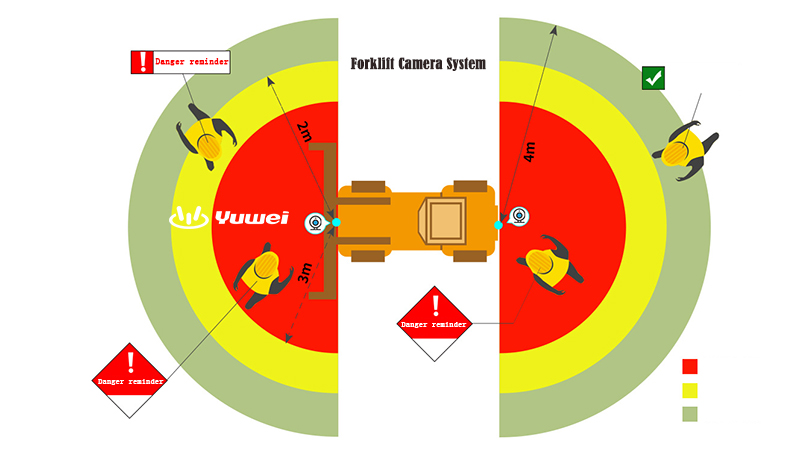

YUWEI’s AI-driven forklift telematics solutions rely on a data intelligence platform, integrating forklift gateways (vehicle condition monitoring, automated pre-inspection, etc.), speed governors, pedestrian detection, and event-triggered digital video recorders.

By combining real-time monitoring, AI insights, and ERP system integration, the solution delivers 360-degree visibilityfrom warehouse to on-road operations. This helps enterprises reduce accidents, comply with OSHA regulations, minimize downtime, enhance productivity, and maximize equipment ROI. In addition, YUWEI provides trainingand customized implementation support.

Four Major Pain Points of Traditional Forklift Management

1. Low Operational Efficiency:Vehicles are scattered, task allocation relies on experience, frequent empty runs and queuing occur, and equipment utilization is less than 40%.

2. Uncontrollable Safety Risks:Overspeeding, failure to wear seat belts, and overloading are hard to monitor in real time, while accident accountability depends on “after-the-fact tracing.”

3. High Maintenance Costs:Fault detection is delayed (e.g., battery anomalies, engine aging), downtime is prolonged, and unplanned stoppages cause daily losses of over 1,000 yuan.

4. Lack of Data Value:Absence of metrics such as mileage, energy consumption, and operating hours prevents data-driven decisions for fleet expansion and equipment renewal.

Telematics + GPS Tracking

The forklift telematics systemis built on GPS positioning, sensors, and wireless communication (4G/5G). Onboard terminals collect data such as location, speed, fuel consumption, and fault codes in real time, then upload it to the cloud to provide managers with visualized, analyzable, and actionabletools.

1. Real-Time Monitoring

① Supports forklift GPS trackingand map visualization.

② Managers can view vehicle location, route, and dwell time via PC or mobile.

③ Automatic alerts are triggered when vehicles deviate from designated areas.

④ Smart dispatch recommendations reduce congestion when multiple forklifts gather.

2. Status Awareness

① Onboard terminals integrate vibration, temperature, and BMS (Battery Management System) sensors.

② Monitors engine, hydraulic systems, and battery health.

③ Low battery voltage triggers charging reminders; abnormal RPM generates diagnostic reportswith recommended service providers.

④ Reduces downtime by more than 70%.

3. Data-Driven Insights

① Automatically generates multidimensional reports: vehicle utilization rate, top 10 energy consumers, driver performance scores, etc.

② Identifies inefficiencies, e.g., analyzing “empty run rate” to adjust cargo placement rules.

③ Compares driver behaviors such as frequent acceleration/braking to guide targeted safety training, reducing accident rates.

Key Functions of Forklift Management Solutions

When selecting a forklift fleet management solution, focus on these core features:

1. Basic Positioning & Route Playback:Dual GPS + BeiDou positioning (≤5m error), historical route storage ≥3 months for auditing and tracing.

2. Geofencing & Boundary Alarms:Customizable work zones and restricted areas with real-time alerts to prevent entry into hazardous zones.

3. Driver Behavior Analysis:Cameras and sensors detect overspeeding, fatigue driving (yawning, eye closure), and failure to wear helmets. Scores are used to optimize workforce management.

4. Energy & Cost Management:Tracks daily/monthly fuel/electricity usage per forklift, calculates unit costs, and supports equipment selection (electric vs. fuel-powered forklifts).

5. Open API Interfaces:Seamlessly integrates with WMS (Warehouse Management System) and ERP, enabling full-chain coordination of orders–vehicles–personnel.

Why Choose YUWEI Forklift Management System?

Advantages:

1. Highly Reliable Hardware:Industrial-grade design, wide temperature tolerance (-30℃ to 70℃), anti-vibration, IP67 protection, suitable for dusty and high-temperature warehouse environments.

2. Smart Warning Algorithms:AI models trained on millions of forklift data points accurately detect collision risks and cargo tilting with ≥95% accuracy.

3. Customized Services:Tailored functions for different warehouse types. For example, cold chain warehouses can add “cargo temperature monitoring,” while e-commerce warehouses can optimize “priority dispatch for hot-selling items.”

4. Full Lifecycle Support:24/7 technical support, deployment cycle ≤2 weeks, operational training, and regular system upgrades for worry-free long-term use.

From manual managementto systematic management, forklift telematics and GPS tracking systems represent more than a tool upgrade—they signify a transformation in management philosophy.

If you are seeking a reliable forklift fleet management software, YUWEI’s solution is worth a deeper look.

Email:hello@yuweitek.com