Construction Vehicle & Heavy Equipment Camera System

Construction Vehicle & Heavy Equipment Camera System

In construction vehicles, challenges such as blind spots in driver visibility, delayed response to sudden events, and difficulty in tracing rule violations have always been major concerns for fleet management. From hidden dangers around excavators during precision operations, to obstructed views when dump trucks are reversing; from monitoring concrete mixers during long-distance transport, to detecting driver fatigue in heavy equipment during daily operations—significant risks exist across all scenarios.

YUWEI introduces a camera system tailored for construction fleets—including excavators, dump trucks, concrete mixers, and other equipment—redefining safety standards with its “HD Vision + AI Alerts + Data Management”triple capability.

The “Safety Blind Spots” of Construction Vehicles

Due to their unique characteristics, construction vehicles face multi-dimensional safety risks:

1. Limited visibility: Excavators create a 3-meter “visual vacuum” around the vehicle during rotation; dump truck cargo boxes obstruct rear vision while reversing; concrete mixers risk collisions in the inner wheel gap during turns.

2. Human error: Fatigue driving, distracted operations (e.g., phone use), and speeding are leading causes of accidents.

3. Management challenges: Traditional monitoring only records video but cannot provide proactive warnings. Dispersed data across multiple devices makes accident investigation time-consuming and inefficient.

YUWEI Solutions

YUWEI systems deliver customized camera combinations based on vehicle type and work scenarios. Core products cover four major applications: driver behavior monitoring, environment awareness, reversing assistance, and remote management—providing true “360° safety protection.”

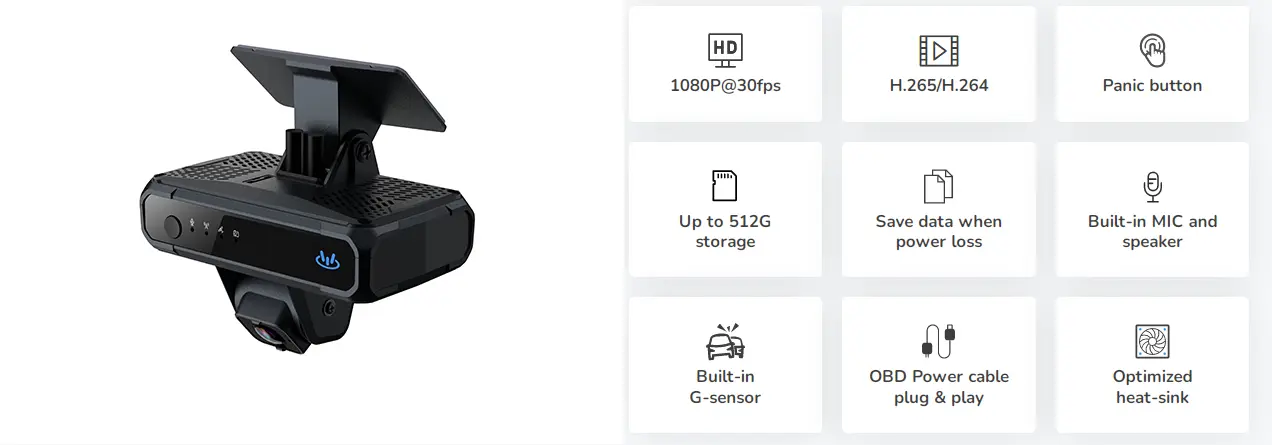

1. V8N Smart Dash Cam

Drivers are the first line of safety, yet their state is difficult to monitor in real time. The YUWEI V8N Dash Camintegrates ADAS (Advanced Driver Assistance System)and DSM (Driver Status Monitoring System)—acting as an “AI driving coach”:

① ADAS features: Monitors distance to vehicles ahead, issuing forward collision warningswhen detecting sudden braking risks; triggers lane departure alertsto prevent accidents caused by distraction.

② DSM features: Infrared camera detects driver facial features, identifying dangerous behaviors like eye closure, yawning, phone use, or smoking—triggering instant audio-visual alerts to prevent fatigue-related incidents.

③ Best suited for: Excavators, concrete mixers, and other vehicles requiring long operating hours. Field tests show a 40%+ reduction in human-error accidents.

2. Waterproof Backup Camera + 360° Surround View

Blind spots during reversing or turning are accident hotspots. YUWEI’s Backup Cameraand 360° Panoramic Systemprovide drivers with a transparent field of vision:

① Reversing: IP67 waterproof design resists mud, water, and harsh conditions; 180° wide-angle lens + night vision ensures obstacles (stones, pedestrians, posts) within 10m behind are clearly visible even at night.

② 360° Panoramic View: Four fisheye cameras stitch real-time vehicle surroundings. Excavators rotating or dump trucks turning can see exact positions relative to the environment—eliminating “visual vacuums.”

3. Mobile DVR F6

Scattered video data has limited value. The YUWEI Mobile DVR F6acts as the fleet’s safety management hub:

① Multi-channel video integration: Supports 4–8 camera inputs (compatible with V8N, DSM cameras, etc.), synchronizing driver behavior, reversing views, and road conditions. In accidents, critical frames can be retrieved quickly—improving liability determination efficiency by 70%.

② Remote monitoring & playback: Via 4G/5G, fleet managers can view any vehicle in real time from phone or PC. Events are searchable by time or tags (e.g., sudden braking, fatigue driving)—eliminating the “needle-in-a-haystack” problem.

③ Rugged stability: Military-grade anti-vibration design withstands bumps, heat, and dust. Operates 72 hours continuously with 99.9% data reliability.

4. DSM Camera (Driver Status Camera)

Beyond the V8N’s built-in DSM, YUWEI also offers a standalone DSM Camerafor specialized needs (e.g., hazardous material fleets):

① High-precision detection: Recognizes micro-expressions (squinting, frowning), head posture (excessive nodding), and even safety helmet use—covering more risk points.

② Custom alert rules: Fleet managers can set flexible alerts (e.g., “mandatory rest after 2 hours driving” or “phone use = instant alarm”), adapting safety standards to different work scenarios.

Why Choose YUWEI?

1. Rugged hardware: All cameras are IP67 waterproof, tested at -40℃ to +85℃, with ABS+PC casing providing 3× stronger impact resistance than standard cameras—reliable against dust, vibration, and corrosion.

2. Scenario customization: Instead of generic solutions, YUWEI offers tailored “camera + algorithm + platform”packages. For example:

① Excavators → 360° rotation monitoring

② Dump trucks → cargo coverage monitoring

③ Concrete mixers → anti-theft material monitoring

YUWEI Construction Fleet Camera System

Through a full-cycle safety approach of proactive warnings, real-time monitoring, and data traceability, YUWEI not only reduces accident rates but also improves fuel efficiency and operational management by optimizing driving behavior (e.g., reducing harsh braking, encouraging steady speeds). A true partner for smarter, safer fleet management.

Email:hello@yuweitek.com