Qatar Heavy Construction Equipment Reversing Camera Systems

Qatar Reversing Camera Systems Supplier

At the Lusail New City construction site in the northwest suburbs of Doha, 30 excavators swing their buckets while loaders unload steel bars from 50 meters away. Amid the roar of machinery, this site marks the core zone of Qatar’s “National Vision 2030”and a battlefield for 32,000 heavy equipment units(as of the end of 2024, including 11,000 excavators and 8,000 concrete mixers).

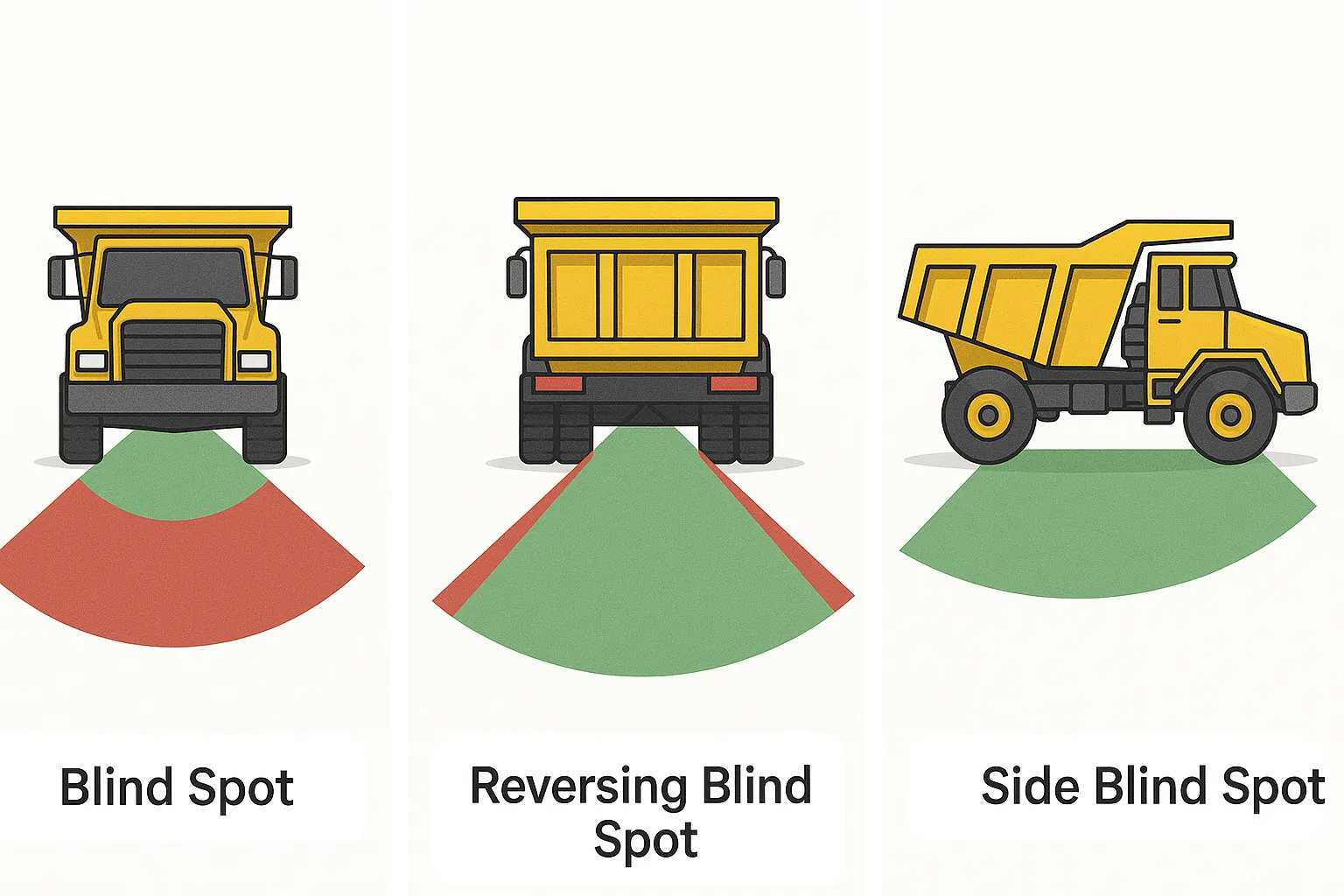

Over 70% of construction accidents are related to reversing(Qatar Safety Report 2024). Traditional “rearview mirror + spotter”methods fail, making reversing camera systems an essential requirement. From concrete mixers to excavators, hardware configurations are tailored to operational needs.

32,000 Units: Reversing Safety as a “Hard Requirement”

Qatar’s infrastructure boom—covering World Cup stadiums, northern gas field expansions, and more—added 12,000 heavy equipment units in 2023. Yet the sheer size of these machines introduces hidden risks:

1. Concrete Mixers: Over 12 meters long, 4–5 meters rear blind spots, turning radius over 10 meters.

2. Excavators: Over 15 meters long, 4–6 meters rear blind spots, swing radius over 8 meters.

3. Environmental Challenges: Surface temperatures exceed 50°C in summer, an average of 60 days of sandstorms per year (PM10 > 800 μg/m³), and insufficient night lighting magnify risks.

2023 Qatar regulations: New equipment must be equipped with ISO 16505 standard imaging systems. Existing machines must be upgraded by the end of 2025. The market has surged from $8 million in 2022 to $32 million in 2024, with an annual growth rate of 100%.

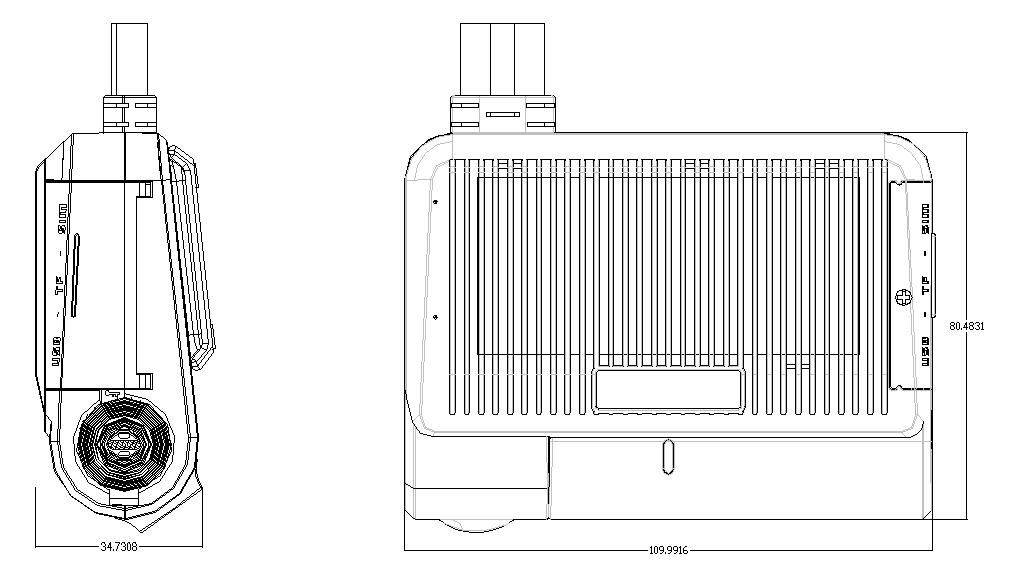

Hardware Breakdown: “Custom Protection” for Mixers and Excavators

Concrete Mixers: 5 Cameras + Multi-Sensor “No Blind Spots”

The YUWEI white mixer(see Figure 1) hardware setup includes:

1. Cab camera: Monitors driver fatigue.

2. Right front & rear blind spot cameras: Cover the A-pillar and right rear blind zones.

3. Rear reversing camera: Centrally located, IP68-rated.

4. Chassis sensors: Ultrasonic radar detects obstacles 0–5 meters.

5. Side millimeter-wave radar (77GHz): Detects moving objects within 10 meters.

Data is processed by an industrial-grade processor(“host”), with the display screensplitting views for full panorama + DSM (Driver Status Monitoring) + radar data. In case of risk, audible and visual alarmstrigger high-decibel beeping and red flashing to enforce stopping.

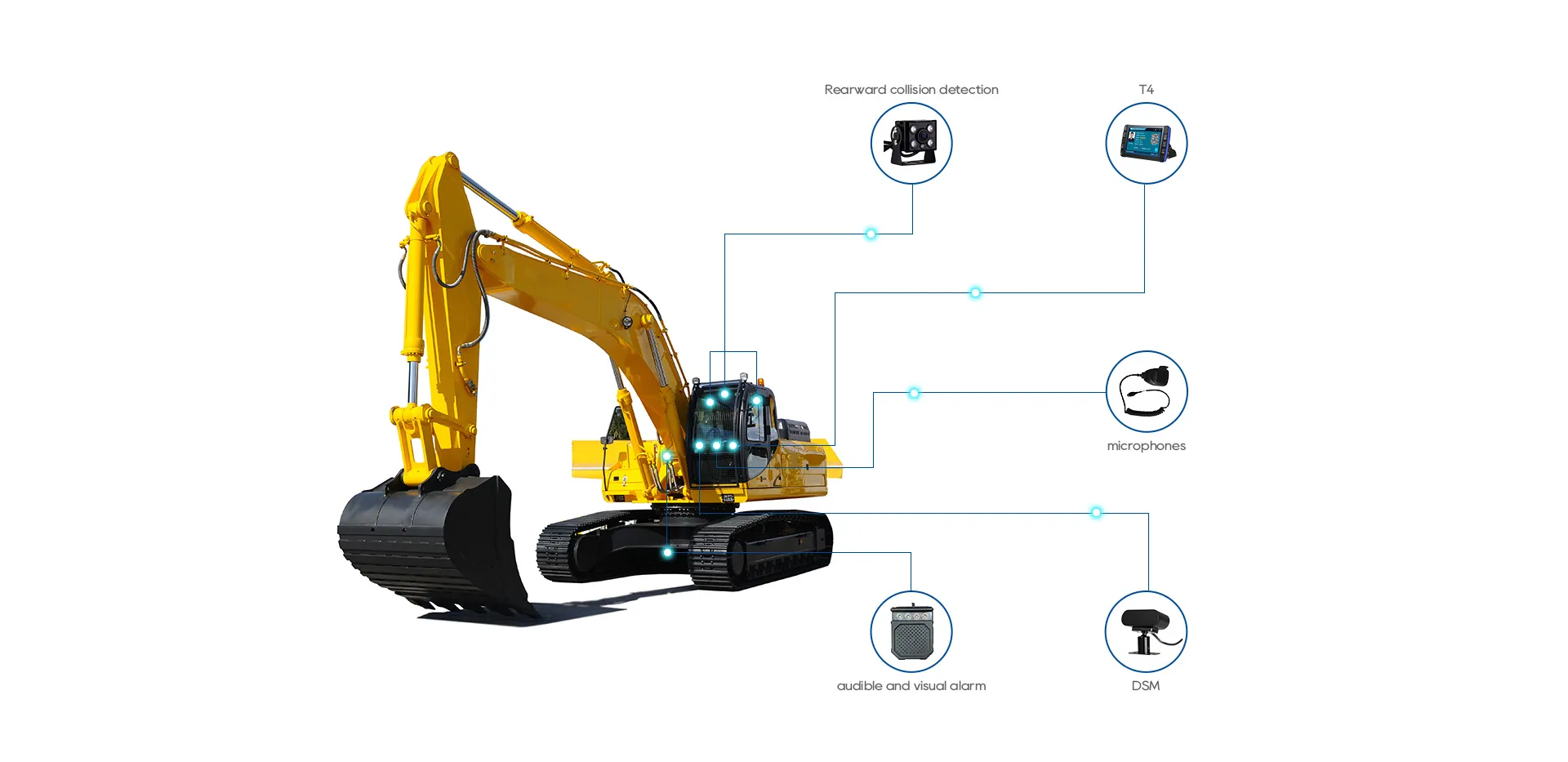

Excavators: Rear Collision Detection + Multi-Modal Alerts

The YUWEI yellow excavator(see Figure 2) is optimized for operational safety:

1. Rear collision detection: Camera + millimeter-wave radar calculate relative speed with obstacles, predicting collisions within 3 seconds.

2. Microphones: Capture environmental sounds (e.g., worker calls) for additional context.

3. T4 Controller: Links detection with hydraulic system response.

4. Alerts: High-frequency buzzer + yellow light warning. DSM monitors operator focus, restricting swing speed in emergencies.

Functional Impact: From “Seeing” to “Managing” Efficiency

At Lusail New City, 20 excavators and 8 mixershave been equipped with these systems:

1. Mixer driver Lina: DSM flagged “distraction” when taking calls while reversing. The system automatically slowed the vehicle and sounded a warning until she refocused. Daily unloading trips increased from 8 to 12.

2. Excavator operator Mohammed: Rear collision detection alerted “toolbox 3 meters behind right rear” 3 seconds before collision. Video review confirmed a worker had temporarily entered a blind spot—the system prevented an accident.

Even in the desert heat, with rotating mixer drums and excavator arms in motion, the “Safety Eye”has woven a digital protective net. From the scale expansion of 32,000 unitsto customized hardware for mixers and excavators, this safety-driven upgrade is making Qatar’s construction sites safer and smarter.

Email:hello@yuweitek.com