Is It the Best AI Dash Cam for Construction Trucks?

Construction Trucks ai DASH CAM

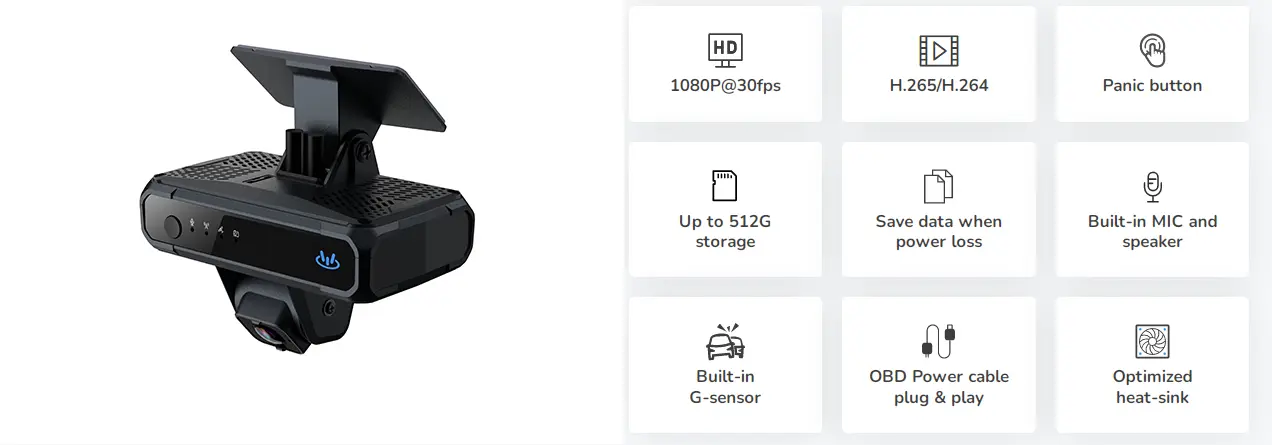

In the field of construction vehicle management, traditional dash cams can no longer meet the complex needs of modern fleets. According to industry data, the accident rate of construction vehicles without intelligent monitoring systems is 37% higher than that of ordinary vehicles, and the downtime losses caused by equipment failures can reach millions of US dollars annually. The V8N AI Dash Cam launched by YUWEI, a leading intelligent on-board device manufacturer, is being widely adopted by construction fleets worldwide and has received high praise from overseas enterprises.

Pain Points in Construction Vehicle Management

1. Difficulties in Monitoring Complex Operating Environments

Construction vehicles often operate in extreme environments such as dusty construction sites and steep job locations. Traditional cameras are prone to light interference, resulting in blurred images at night. The V8N adopts a starlight-level CMOS sensor (SONY IMX335 / SmartSens SC200 AI), which can output 1080P high-definition images even under 0.1Lux illumination. Equipped with infrared fill light technology, it achieves 24/7 all-round monitoring with no blind spots.

2. Difficulty in Controlling High-Risk Driving Behaviors

Data from the U.S. Bureau of Labor Statistics shows that distracted driving accounts for 42% of construction vehicle accidents. The built-in DMS (Driver Monitoring System) of the V8N can real-time identify:

① Fatigue driving (eye closure / yawning)

② Distracted operations (mobile phone use / smoking)

③ Unfastened seatbelt / abnormal posture

When dangerous behaviors are detected, it immediately triggers a voice alert and synchronizes the information to the management platform.

3. Prominent Safety Hazards in Blind Spots

Construction machinery generally has visual blind spots. The YUWEI V8N innovatively integrates BSD (Blind Spot Detection) function. Through external cameras, it real-time captures images of the right blind spot, and with dynamic object recognition algorithms, issues collision warnings 1.5 seconds in advance, effectively reducing the risk of lane-change accidents.

Technical Advantages of the V8N

Function Module | Technical Parameters | Industry Breakthroughs |

Video Recording | Dual-channel recording (Front: 1080P + Interior: 720P) | Supports 4 TF card expansion (2TB per card) |

Positioning Accuracy | Dual-mode GNSS (Beidou + GPS) | Real-time positioning error < 2 meters |

AI Algorithms | Recognizes 22 high-risk driving scenarios | Customizable alert thresholds |

Environmental Adaptability | IP67 waterproof & dustproof / -40℃ ~ 85℃ temperature resistance | Certified by FCC / CE / ISO9001 |

Comparative Advantages Over Traditional Devices

Dimension | Traditional Dash Cams | YUWEI V8N AI Dash Cam |

Monitoring Dimensions | Single-channel video + Basic GPS | 4-channel video + ADAS + DMS + BSD |

Data Application | Post-event review | Real-time alerts + Cloud data analysis |

Installation Complexity | Professional wiring required | Wireless transmission + Magnetic quick-install design |

Cost-Effectiveness | Annual maintenance cost per vehicle: $500+ | Reduces insurance rates / Minimizes accident losses |

Typical Application Scenarios

① Mining Transportation Fleets: Prevent tire blowout accidents via ADAS; monitor driver fatigue with DMS.

② Municipal Engineering Vehicles: Avoid intersection collisions using blind spot monitoring; manage restricted areas with electronic fences.

③ Port Machinery Equipment: Optimize scheduling through GPS trajectory playback; use video evidence chains to address legal disputes.

The YUWEI V8N is more than just a recording tool—it is the digital core of intelligent construction vehicle management. Its integrated architecture supports multi-system collaboration, enabling seamless connection between driving behavior analysis, vehicle status monitoring, and remote dispatch management. Through AI algorithms, it identifies high-risk operations and generates optimization suggestions, helping enterprises establish standardized safety management systems. Combined with the cloud platform, it can perform aggregated analysis of large-scale fleet data, providing visual support for operational decision-making. With an IP69K protection rating, the device adapts to extreme working conditions and ensures long-term stable operation.

Email:hello@yuweitek.com