Canadian Mining Truck Tracking and Management System

Canadian Mining Truck Tracking Management System

As one of the world’s leading mining nations, Canada operates a massive fleet of mining trucks. It is estimated that over 5,000 mining trucks(including dump trucks, articulated trucks, etc.) are currently in use across active mining operations. These are primarily concentrated in key mining regions such as Alberta(oil sands), Ontario(gold, nickel, copper), and Quebec(iron and lithium).

Smart Fleet Management Upgrade: YUWEI’s Solution for Cost Reduction and Efficiency Enhancement

Industry Challenges: Traditional Methods Under Pressure

The mining transportation sector faces three major issues:

a. Positioning Blind Spots: GPS signals are often unreliable in open-pit areas and completely unavailable underground.

b. Loose Cost Control: Fuel anomalies, abnormal tire wear, and empty trips are difficult to monitor effectively.

c. Safety Risks: Speeding, fatigue driving, and other violations lack proper oversight.

Surveys show that over 90% of mining companiesstill rely on manual dispatching, resulting in high transportation costs and limited efficiency improvements.

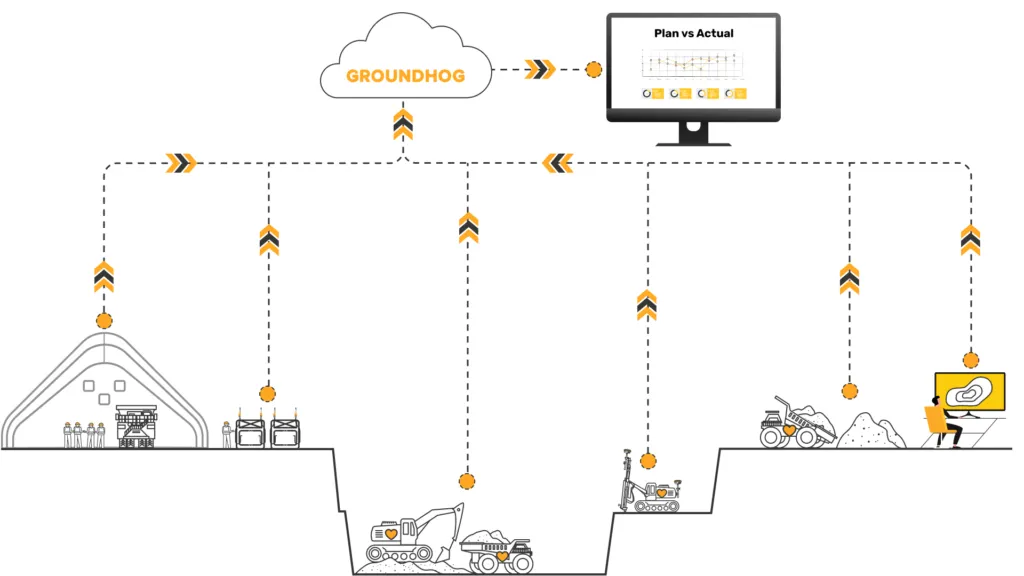

Key Breakthroughs for Intelligent Management

1. All-Scenario Precision Positioning Solution

YUWEI utilizes innovative multi-modal positioning technology:

a. Open-Pit Zones: GPS + BeiDou dual-system enhanced positioning, with accuracy within 2 meters

b. Underground Operations: UWB (Ultra-Wideband) network achieves 0.3-meterprecision

c. Transition Areas: Inertial navigation ensures continuous tracking for up to 40 minutes without a signal

Real-world application: Positioning availability increased from below 70% to over 99%.

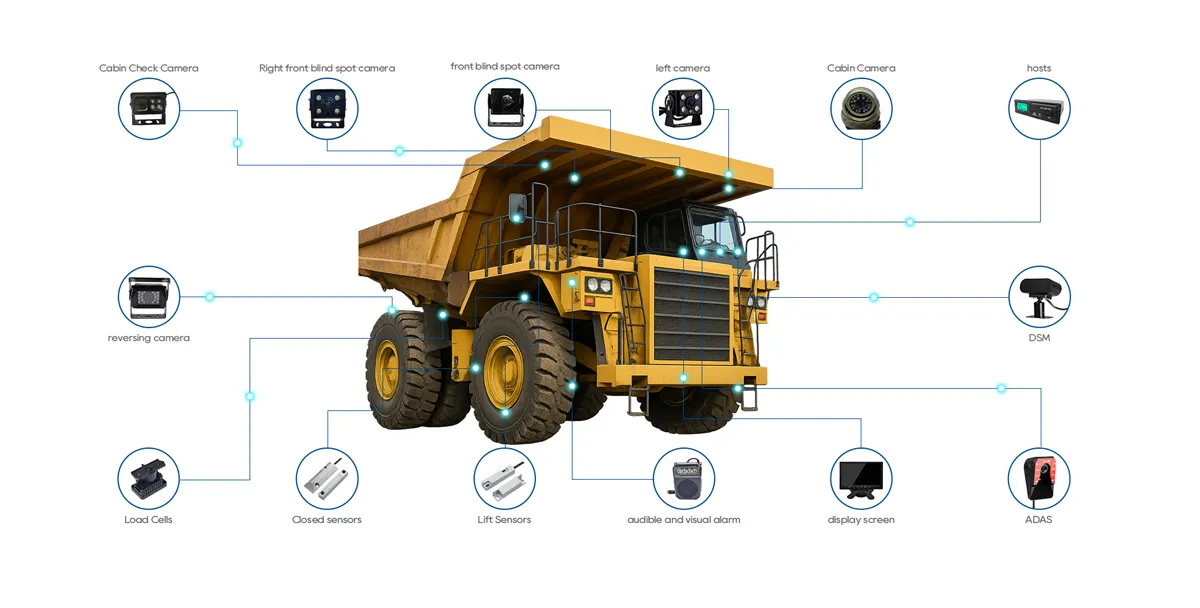

2. Refined Operational Management System

a. Dynamic Load Monitoring: Smart sensors provide real-time load data with less than 1.5% error

b. Full-Cycle Fuel Monitoring: Tracks fuel usage from refueling to consumption, eliminating abnormal losses

c. Intelligent Dispatch Algorithm: Automatically optimizes routes, reducing single-trip time by 15%

3. Predictive Maintenance System

By analyzing equipment operating data, YUWEI can detect potential issues early:

a. Engine Anomalies: Warnings issued an average of 14 daysin advance

b. Tire Wear: Real-time monitoring of pressure and temperature

c. Drivetrain Health: Vibration analysis identifies early-stage faults

YUWEI Solution: Core Advantages

Compared to traditional systems, YUWEI delivers clear benefits:

1. More Comprehensive Coverage: Seamless tracking across all mining environments

2. Higher Data Accuracy: Leading precision in monitoring critical parameters

3. Superior System Compatibility: Easily integrates with various management platforms

4. Faster ROI: Typical customers see a full cost recovery within 6 months

Proven Success Cases

Case Study: Large Coal Mine in Inner Mongolia

1. Transportation cost per ton of coal reduced by 27.5%

2. Monthly downtime from failures reduced by 78%

3. Annual total savings exceeded $12 million USD

Case Study: Copper Mine in Chile

The system maintained stable and reliable performanceeven in a complex cross-border operating environment.

Implementation Pathway Recommendations

1. Flexible Plan Selection: Choose between Basic or Advanced versions based on operational needs

Dedicated Service Channel

We offer:

1. Customized Cost-Benefit Analysis Reports

2. Industry-Specific Solution Whitepapers

3. Full support from our Professional Technical Team

Email:hello@yuweitek.com