4G Single-lens Dash Cam

4G Single-lens Dash Camera

The China YUWEI V5 is a highly cost-effective 4G LTE dash cam. It utilizes 4G Cat.1 network communication and supports dual BDS+GPS positioning. In the event of collisions or emergencies, the V5 rapidly uploads short video clips of the incidents to a server for storage. It also triggers real-time alerts to operators, ensuring vehicle driving safety. The V5 features driver behavior analysis, various abnormality alarms, and facilitates real-time vehicle condition monitoring to enhance cost-effectiveness in fleet management. It meets the remote management needs of fleet vehicles including private cars, ride-hailing vehicles, taxis, automobile finance and insurance, as well as government or corporate fleet vehicles.

4G Single-lens Dash Cam Features:

- Dual-mode positioning

- Real-time BDS+GPS positioning to track vehicle location

- 4G communication

- 4G Cat.1 for smoother communication

- Driver behavior analysis

- Automatically alerts on dangerous driving behaviors like sudden braking, acceleration, sharp turns, and speeding

- Event alarms

- Automatically captures event photos in case of low external power, collisions, or abnormal vibrations

- Real-time monitoring

- Supports remote viewing of real-time videos from multiple vehicles

- Compact and easy installation

- Can be discreetly installed behind the rearview mirror on the windshield, without obstructing the driver's line of sight

4G Single-lens Dash Cam Specifications

Parameter classification | Parameter item | Details | Remark |

Basic parameters | Appearance | device integrate with ADAS cam | |

Product Type | 4G DVR Car Video Terminal | ||

network standard | 4G Global Band | ||

Memory | 256MB(Flash)+1GB(DDR) | ||

Front camera | 1080P, MIPI Camera, H:112°V:55° | ||

In-car camera | AHD 720P, with light sensor/infrared night vision, | ||

AHD Camera, single pass, infrared night vision, H=60° V=42° | |||

4th Channel camera | AHD 720P | ||

Hardware function

| GPS | Support: GPS+BDS | |

Wi-Fi | 802.11b/g/n | ||

trumpet | 8 ohms 1.5 watts, 1 channel, with sound cavity | ||

MIC | Built-in dual silicon microphone design | ||

Accelerometer | 3-axis accelerometer | ||

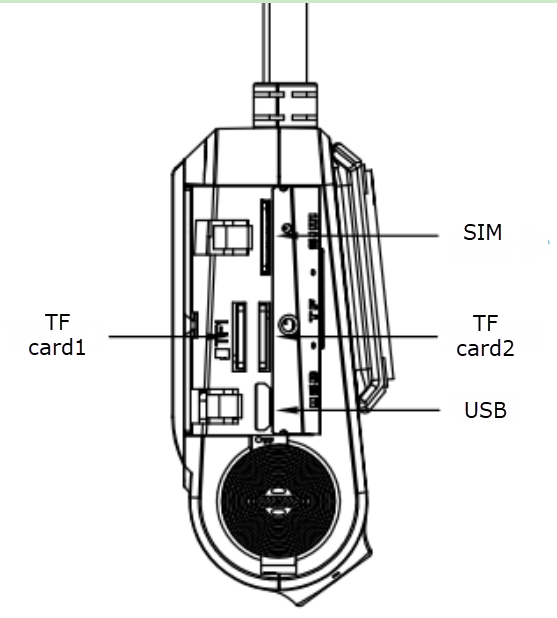

Interface | micro 5Pin USB | USB×1, data interface | |

BMW connector | Power+/GND ACC Left turning signal cable Right turning signal cable SOS Cable (Panic button) | ||

RS232 | 1*RS232 | ||

SIM card holder | Micro SIM | ||

TF card holder | TF×2 (Card 1 and Card 2 support circular storage) | ||

Power supply | Power supply | 12V/24V power supply | |

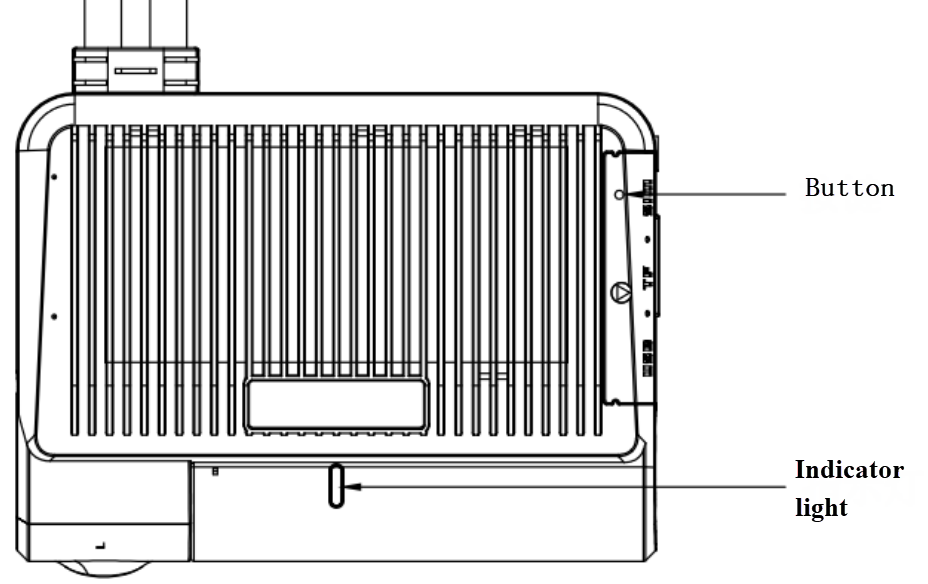

Button& Indicator light

| Reset button | Long press the power button for 8 seconds to reset | |

indicator light | 2-color indicator | ||

Alarm key | Standard emergency alarm connector | ||

Antenna

| GPS Antenna | Built-in ceramic antenna | |

4G antenna | Built-in FPC+IPEX transposon | ||

WIFI antenna | Built-in FPC+IPEX transposon | ||

Memory card | 4G~2TB, patented DXR streaming storage format | ||

Electrical Specification | Operating temp. | -20℃~70℃ | |

Storage temp. | -40℃~85℃ | ||

Static Protection | 6KV contact, 10KV air | ||

Vibration test | Car vibration | ||

Current consumption | When the working voltage is 12V, the current is from 500mA to 1A (depending on whether the algorithm is turned on, etc.) When ACC OFF: ≤3mA | ||

Other quality requirements | According to JT/T794 standard (including hard test, soft test, reliability, quality, etc.) | ||

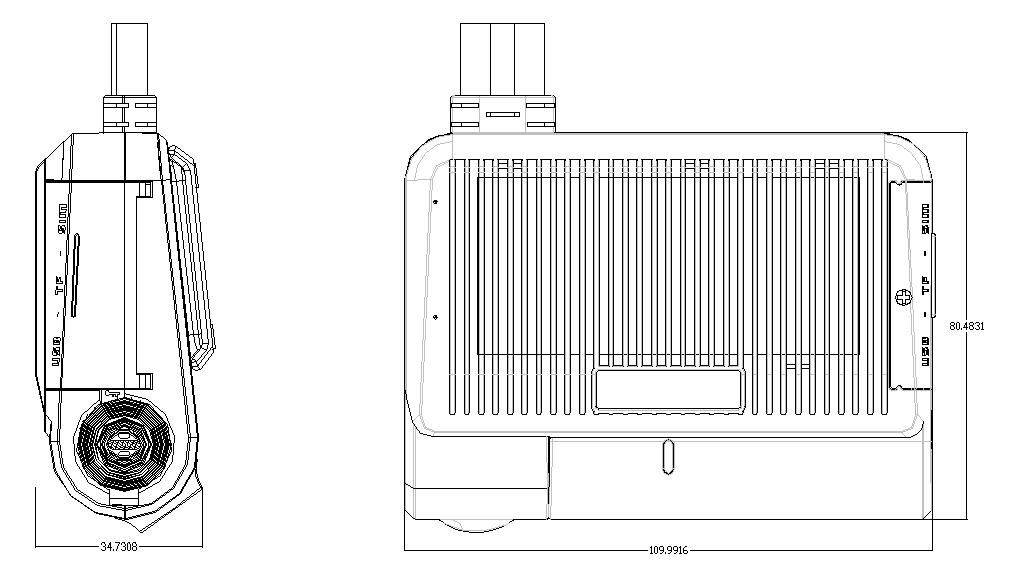

Product specification pictures:

hnweb_

l Red light

Equipment situation | Light status |

Before the program is ready | Solid on |

during upgrade | On for 1 second, off for 4 seconds |

update completed | |

camera lost | On for 0.1 seconds, off for 0.1 seconds, flashing 4 times at a time, flashing once every 4 seconds |

SIM card missed | On for 1 second, off for 1 second |

other status | Always off |

l Green light

Equipment situation | light status |

Before the program is ready | Solid on |

during upgrade | On for 1 second, off for 4 seconds |

update completed | |

The card is recording normally | On for 1 second, off for 1 second |

Unrecorded card abnormal | On for 0.1 seconds, off for 0.1 seconds, flashing 4 times at a time, flashing once every 4 seconds |

other status | Always bright |

TF card/SIM card/USB location

More:Fleet Dash Cam Systems | Backup Camera for Dump Truck | Backup Camera System for Cargo Van