Concrete Truck Fleet Management System

Concrete Truck Fleet Management

In North America’s construction industry, concrete trucks are the “lifeblood” that fuels urban development—from high-rise apartments to transoceanic bridges, every cubic yard of concrete must be delivered with precision, relying on efficient fleet scheduling and management.

However, the latest 2024 report from the Portland Cement Association (PCA) reveals that around 62% of U.S. concrete truck fleets face a triple challenge: high operating costs, low efficiency, and safety risks, with rough management alone causing an estimated $3.7 billion in additional annual expenses.

Fleet Management Challenges for Concrete Trucks

Before diving into technical solutions, let’s use data to uncover the reality of U.S. concrete fleet operations:

1. Low Dispatch Efficiency & High Empty Mileage

According to Frost & Sullivan’s 2023 commercial fleet study, U.S. concrete fleets experience an average of 2.3 hours of dispatch delays per daydue to “lack of real-time vehicle visibility,” with empty mileage exceeding 18%.

Example: A mid-sized Chicago fleet, unable to track trucks in real time, once had three trucks queue at the same job site, generating $2,000/day in extra idling fuel costs.

2. Driver Behavior

Data from the U.S. National Highway Traffic Safety Administration (NHTSA) shows that concrete trucks have a 42% higher accident ratethan regular freight trucks due to their size and blind spots.

60% of accidents are directly linked to fatigue driving, drunk driving, distracted driving (e.g., mobile phone use), or speeding. Traditional manual spot checks cover only 10–15% of driver behavior, leaving major risks unaddressed.

3. Fuel & Maintenance Costs

Fuel accounts for 35–40% of single-trip transport costs. The American Transportation Research Institute (ATRI) found that aggressive acceleration, idling, or fuel theft results in 12–15% average annual fuel waste.

Equipment failures—such as abnormal mixer drum wear—often go undetected without real-time monitoring, causing sudden breakdowns that cost around $8,000 per incidentin production losses.

Why Traditional Tools Fail

Many fleets have tried basic GPS tracking or dashcams, but with limited success:

1. Single-function– Only records location, no driver behavior analytics or operational data linkage.

2. Data delay– Offline storage makes incident investigation difficult, preventing real-time decision-making.

3. Poor compatibility– No integration with dispatch systems or ERP software, creating data silos.

YUWEI Concrete Truck Fleet Management System

Addressing these pain points, China-based YUWEI has launched its Concrete Truck Fleet Management System, centered on telematics + GPS tracking. Combining all-scenario hardware coveragewith an AI-powered software platform, it provides a complete solution for vehicle monitoring, behavior management, cost optimization, and safety assurance.

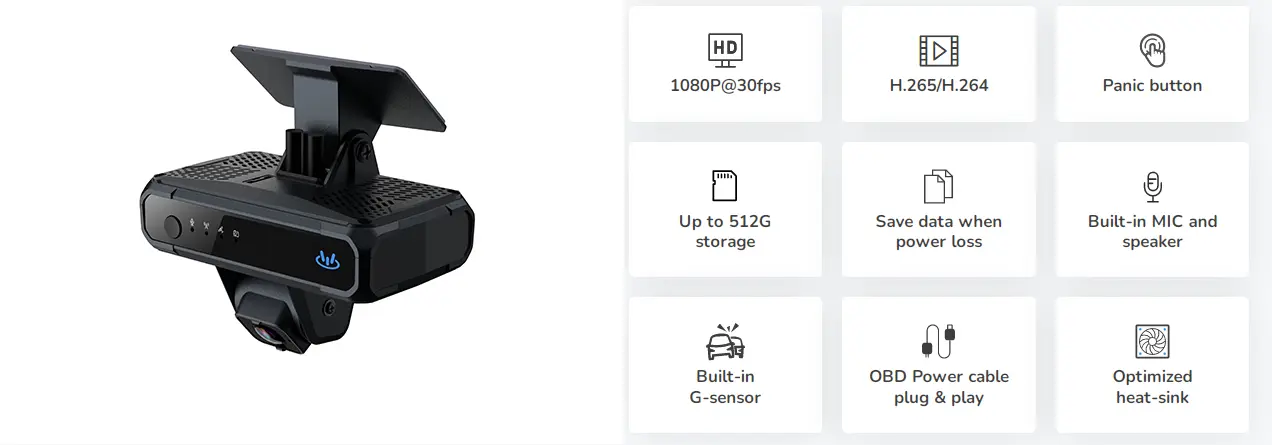

1. Hardware

Designed specifically for concrete trucks (with rugged site conditions, dust, and multiple blind spots), YUWEI’s hardware includes:

① GPS-enabled AI Dash Cam– Supports ADAS (Advanced Driver Assistance Systems) and DMS (Driver Monitoring Systems), with high-precision GPS for real-time speed/location and sudden maneuver detection. Comes with an 8-inch in-vehicle display for navigation and alerts.

② 360° Panoramic Monitoring– Rear-view + 360° cameras eliminate blind spots, reducing collision risk during reversing or turning.

③ Fuel Sensors– Connect to ECU via OBD for real-time fuel consumption monitoring (±2% accuracy), detecting theft and idling waste.

④ Audio-Visual Alarm + Intercom– Alerts for fatigue, speeding, or route deviation, with instant driver warnings and simultaneous remote alerts to the control center.

⑤ Mobile DVR– Stores 1080P HD video with collision-triggered auto-lock; quick retrieval of footage meets FMCSA evidence requirements.

2. Software

Cloud-based, accessible via PC, mobile, or tablet, the software addresses three core pain points:

① Real-Time Tracking & Smart Dispatch– GPS location accuracy ±5m; view all vehicles, routes, and ETAs; system auto-generates optimal dispatch plans, reducing empty mileage by 15–20% (based on U.S. Midwest fleet tests).

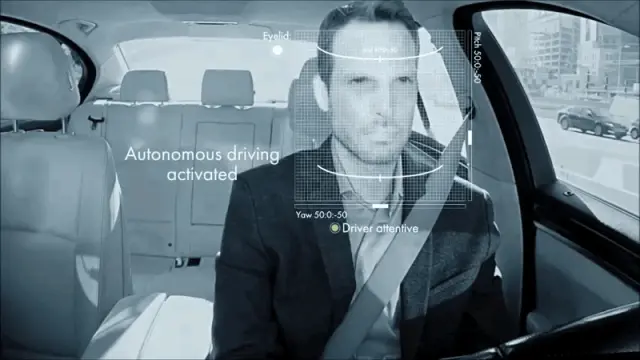

② ADAS + DMS Driver Monitoring & Alerts– AI detects yawning or eyes closed >2s (fatigue alert), phone use/smoking/looking down (distraction alert), and aggressive maneuvers (dangerous driving alert). Data syncs to backend for driver behavior reports and targeted training. One California fleet saw a 32% accident reductionafter adoption.

③ Cloud Storage & Advanced Reports– Encrypted 24/7 data storage with multi-dimensional reports: fuel consumption per vehicle, driver violations, empty mileage analysis, and more—helping fleets plug cost leaks and optimize operations.

Why U.S. Fleets Choose YUWEI

Compared to local competitors, YUWEI offers:

1. Cost-effectiveness– Hardware costs 20–30% lower; software is annual subscription-based, with no high upfront fees.

2. Localized Adaptation– English/Spanish interface; devices tested from -40°C to 85°C for extreme North American site conditions.

3. Technical Superiority– Proprietary AI achieves 98.7% accuracy in fatigue and risky behavior detection; integrates with mainstream fleet management software.

For concrete truck fleets, “Concrete Truck Fleet Management System” and “Telematics + GPS Tracking” are no longer optional tools—they are survival essentials.

For more information, please contact YUWEI.

Do you want me to also prepare this as a professionally formatted brochureversion with headings, bullet points, and marketing tone for presentation to U.S. clients? That would make it look like a ready-to-use sales document.

Email:hello@yuweitek.com