Fleet Management System for Mining

Mining Fleet Management System

In mining operations, challenges such as complex road conditions, high-intensity workloads, and limited visibility not only threaten fleet safety but also restrict production efficiency. A range of intelligent mining fleet management systems has emerged to address these issues. Among them, YUWEI Open-Pit Mine FMS and YUWEI Mining Fleet Management System empower the industry by focusing on full-process optimization and safety protection respectively.

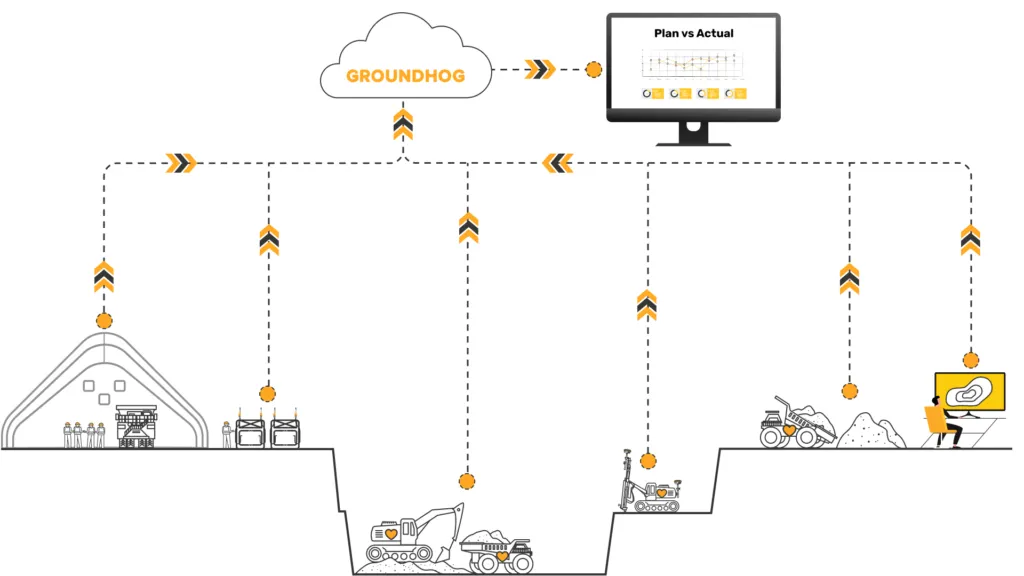

YUWEI Open-Pit Mine FMS

YUWEI Open-Pit Mine FMS aims to increase production and control costs by building a full-process management system from the working face to the central office. It continuously monitors surface operations to maximize ore recovery rates and equipment utilization.

(1) Intelligent Dispatching for Enhanced Efficiency

Equipped with an AI dynamic dispatching algorithm, the system collects loading and transportation data in real time to realize dynamic allocation of mining trucks and loading equipment. It supports both automatic dispatching and manual assignment, automatically pushes optimal routes with real-time adjustments, and traces driving data via GPS playback. This minimizes queuing and idle time, boosting the overall equipment effectiveness (OEE).

(2) Digital Data Management

Replacing traditional paper-based records, the system enables real-time digital collection of production data covering drilling, blasting, loading, and transportation. Leveraging on-board telemetry and tablet GPS, it tracks loader cycles, automatically judges equipment status, and monitors key metrics such as load capacity, drilling volume, and transportation trips in real time, improving data accuracy and timeliness.

(3) Full-Chain Collaborative Optimization

Integrating on-board telemetry, fuel monitoring, and load detection functions, the system automatically collects equipment data to monitor fuel consumption, engine working hours, and other parameters. It prioritizes fuel supply planning and intelligently recommends maintenance intervals. With high-precision GPS, it tracks material flow throughout the process, updates geological information, and monitors stockyard inventory and ore grades, avoiding mis-transportation and redundant handling.

(4) Equipment Maintenance & Safety Assurance

The system monitors equipment indicators in real time and automatically generates maintenance work orders. Equipment status is synced via the dashboard for quick fault response. Condition-based maintenance is implemented based on telemetry data to track key equipment operation and maintenance metrics. Integrated positioning, proximity detection, and collision warning systems automatically trigger alarms or shutdowns to reduce safety accidents. A suite of dedicated software is provided to enhance functional synergy.

The system adopts an advanced technical architecture, is deployed on mainstream tablets, and features a user-friendly interface. It automatically collects data through various devices, supports multiple transmission methods, integrates with third-party software via open APIs, and collaborates seamlessly with multiple systems on the YUWEI platform.

YUWEI Mining Fleet Management System

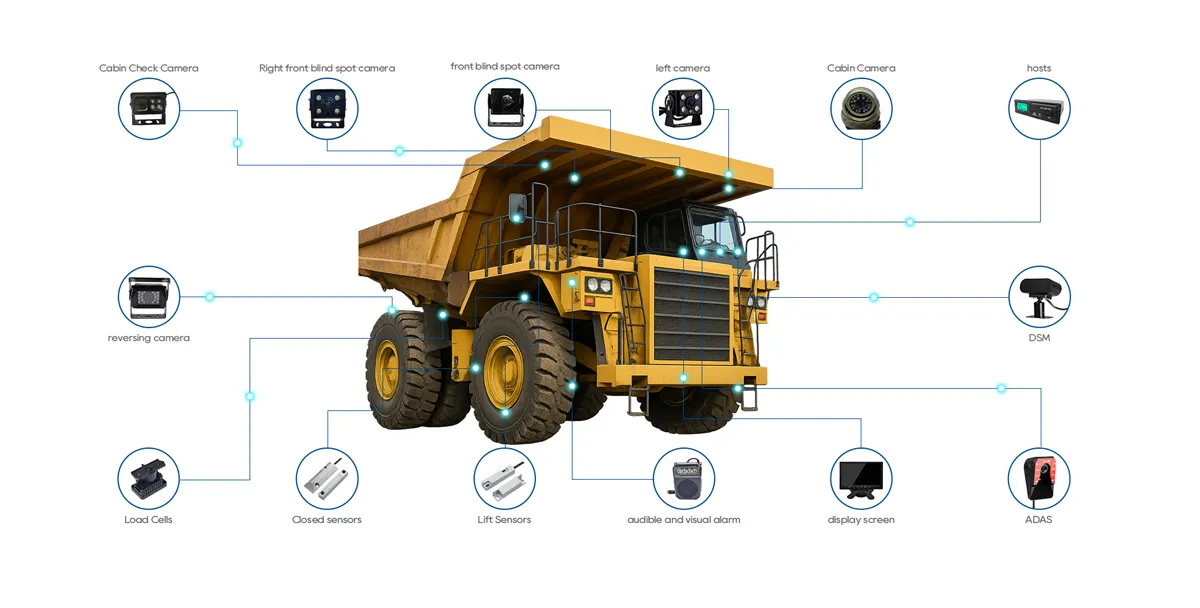

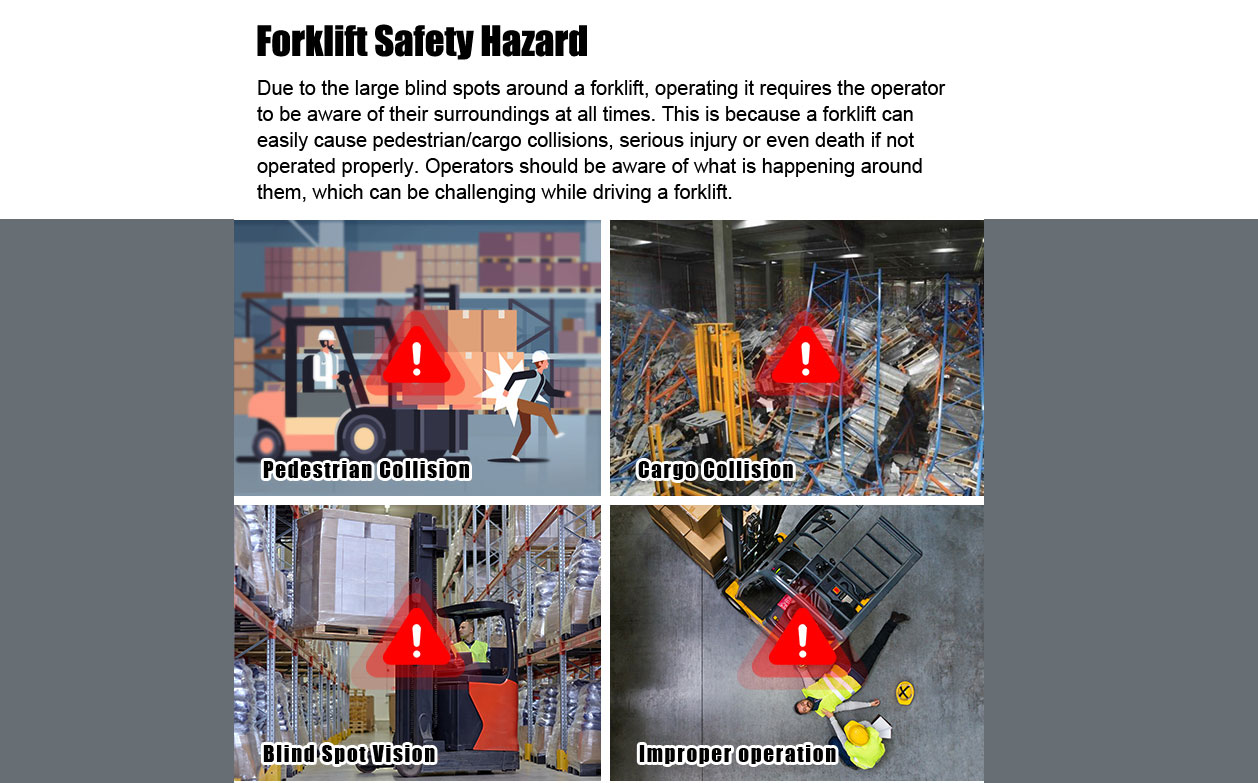

Targeting safety hazards in mining operations, the YUWEI Mining Fleet Management System leverages core technologies such as AI monitoring and radar detection to enhance driver safety awareness, reduce accident rates, and ensure efficient transportation operations.

(1) Driver Status Monitoring

Equipped with a Driver Monitoring System (DMS), the system analyzes fatigue behaviors (e.g., eye closure, yawning) and dangerous operations (e.g., smoking, phone usage) in real time, issuing timely alerts to standardize driving habits.

(2) Vehicle Surrounding Safety Protection

The system is equipped with blind spot detection and radar collision warning systems to monitor the surrounding environment in real time and trigger alarms upon detecting obstacles. The 360° panoramic monitoring, integrated with high-definition night vision cameras, provides clear visibility in complex environments to facilitate precise vehicle control.

(3) Data-Driven Management & Analysis

The system accurately records driver and vehicle performance indicators, automatically generating daily, monthly, and annual reports. These reports provide data support for managers to optimize safety management and operational strategies.

(4) Flexible Product Combinations

① Driver Monitoring System (DMS): Core components include a DMS camera and management platform, supporting positioning, data storage, and multi-dimensional monitoring. Optional accessories include voice prompts and night vision cameras.

② Radar Detection System: Core components include a control unit and detection radar. Adopting millimeter-wave technology with a detection range of 40 meters, it supports three-level early warning and can be paired with displays and night vision cameras.

Conclusion

YUWEI Open-Pit Mine FMS covers multiple links including dispatching, data management, and equipment maintenance, focusing on full-process efficiency optimization. The YUWEI Mining Fleet Management System prioritizes safety protection to build a solid defense line for transportation safety. With distinct features, the two systems will drive the transformation of mining fleets toward greater safety, efficiency, and digitalization, supporting the sustainable development of the mining industry.

Email:hello@yuweitek.com