GPS/BDS real-time positioning:

Each truck needs to be equipped with a GPS or BDS positioning device. This device will obtain location information through a satellite receiver and transmit the data to the server via a communication module.

ADAS/DSM/HOD auxiliary system:

Configure DSM (Driver State Monitoring), HOD (Head-Up Display), and ADAS (Advanced Driver Assistance Systems) intelligent video detection functions to achieve driver behavior detection and driving safety warning through facial feature recognition analysis and intelligent image recognition algorithms.

ADAS | DSM | HOD | BSD |

Forward collision warning | Fatigue driving warning | Hands off the steering wheel | Right Blind Spot Detection |

Proximity warning | Distracted driving warning | Mobile phone usage detection | Blind Spot Alarm |

Lane departure warning | Smoking warning | Seat belt detection | Audio-Visual Warning |

Solid line crossing warning | Camera obstruction |

|

|

Pedestrian collision warning (optional) | Phone usage warning |

|

|

| Leaving driver's line of sight |

|

|

| Active photography function |

|

|

| Driver identification |

|

|

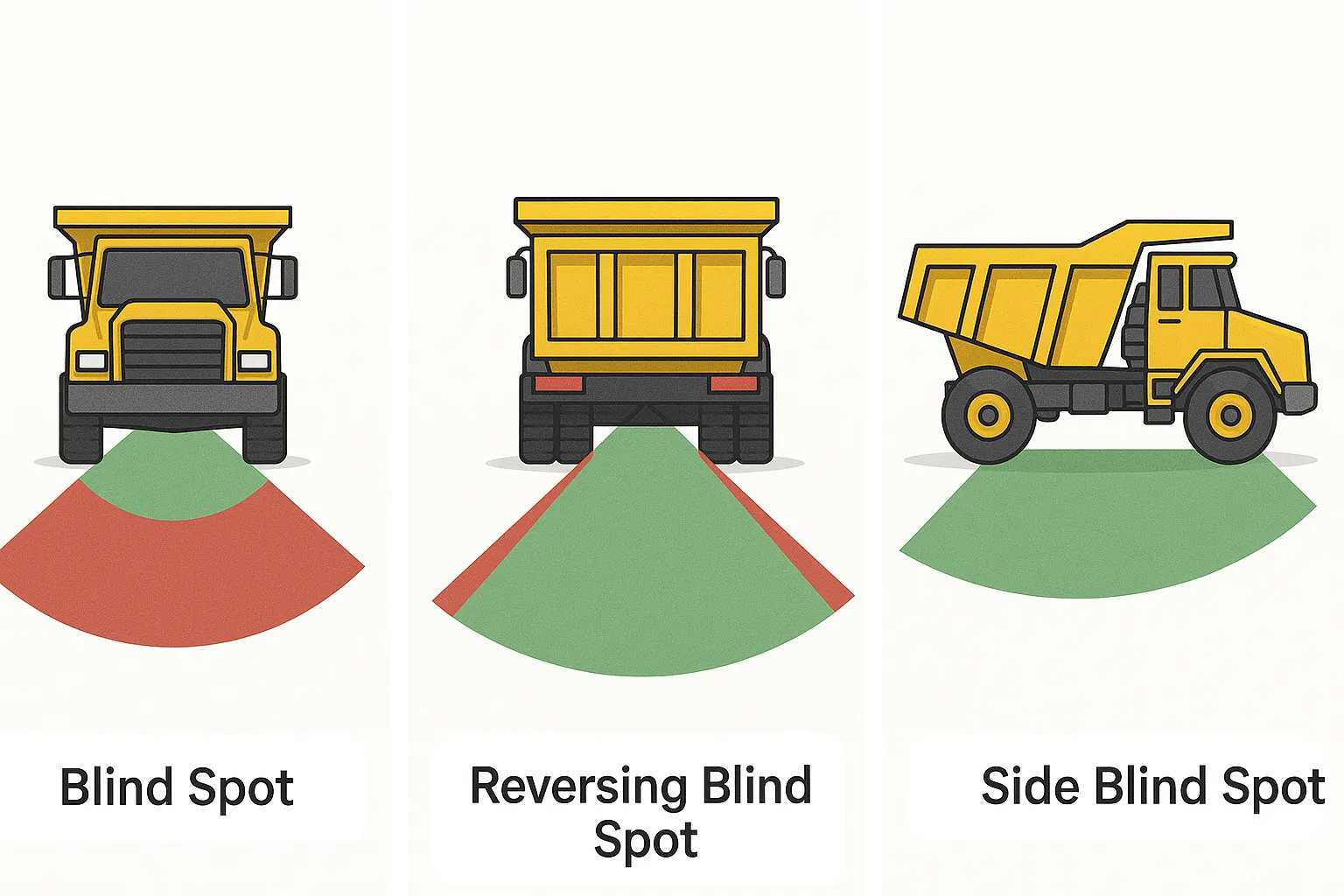

Resolution for blind spot accidents:

BSD (Blind Spot Detection) monitoring: wide blind spot coverage, proactive warning, high accuracy, adaptable to the environment.

Driver reminder inside the vehicle: The main horn emits a "beep, beep" sound; the in-vehicle display shows a warning icon.

Pedestrian reminder outside the vehicle: External sound and light alarm triggers, lights flashing, and voice broadcasting "Danger, please keep away."