Pilbara Mine Truck Camera System Fleet Tracking Management

Pilbara Mine Truck Camera System

Challenges of Transportation and Fleet Management in the Pilbara

As one of the world’s key iron ore producing regions, the Pilbara area of Western Australia faces unique challenges in mine truck fleet management. Fleets typically consist of dozens to hundreds of heavy-duty mining trucks, each traveling more than 200 km per day under extreme environmental conditions.

Overview of Pilbara Mine Truck Fleet Operations

• Typical fleet size: Medium mines operate about 50–100 trucks; large mines can exceed 200–300 trucks

• Daily transport volume: Each truck averages 15–20 trips per day, with a payload of 150–300 tons per trip

• Annual transport volume: Large mines can transport several hundred million tons of ore annually

• Operating costs: Fuel accounts for 30–40% of operating costs; labor costs account for 20–25%

• Accident rate: Under traditional management, there are approximately 3–5 minor accidents and 0.1–0.3 major accidents per 1,000 truck trips

The Pilbara’s harsh environmental conditions—extreme heat (summer temperatures exceeding 45 °C), strong UV radiation, large-scale dust storms, and vast, complex mining terrain—impose stringent requirements on fleet management. Traditional methods struggle to meet the demands of modern mining operations for efficiency, safety, and cost-effectiveness.

Value of Mine Truck Camera Systems in the Pilbara

Safety Improvements

The mine truck camera system delivers significant safety benefits:

• Accident reduction: ADAS and DMS early-warning functions reduce collision accidents by 30–50%

• Fatigue prevention: Driver monitoring systems detect and intervene in over 90% of fatigue-related driving behaviors

• Blind spot prevention: 360-degree panoramic and blind spot monitoring reduces blind spot–related accidents by over 70%

• Violation control: Real-time monitoring of speeding, seatbelt use, and other violations regulates driver behavior

Operational Efficiency Optimization

Combining camera systems with fleet management enhances operational efficiency:

• Reduced empty runs: Intelligent dispatching lowers empty mileage by 25–40%

• Predictive maintenance: Driving behavior analysis extends vehicle lifespan by 15–25%

• Productivity: Accurate work monitoring increases per-truck daily transport capacity by 10–20%

• Response speed: Rapid identification of accidents and faults cuts downtime by more than 30%

Cost Control and Risk Management

• Insurance: Improved safety records lower insurance premiums by 10–20%

• Accident losses: Reduced major accidents minimize direct and indirect economic losses

• Compliance costs: Automated safety monitoring reduces inspection and management costs

• Fuel efficiency: Optimized driving behavior lowers fuel consumption by 5–15%

YUWEI Mine Truck Camera System Solution

To address the Pilbara’s unique environment and operational demands, YUWEI provides a complete mine truck camera and fleet tracking management system, successfully deployed in multiple Australian mines.

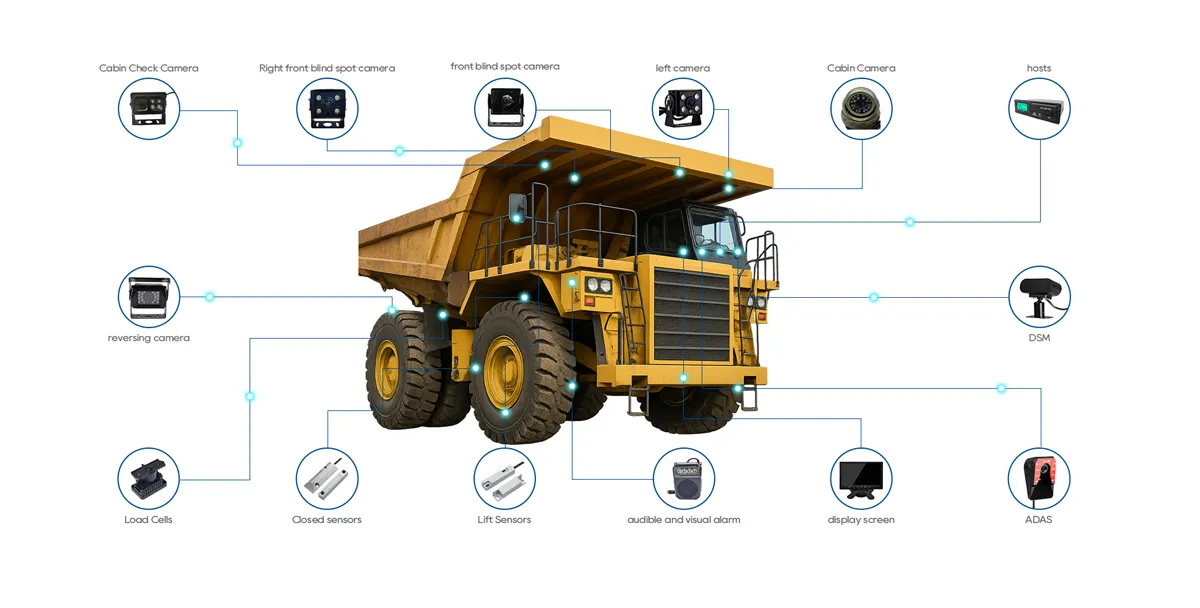

System Hardware Components

1. Forward ADAS Camera (1080P HD)

• Function: Monitors road conditions; provides forward collision warnings and lane departure alerts

• Features: Wide Dynamic Range (WDR) for high contrast lighting; IP69K rating for dust, water, and heat resistance

• Installation: Front windshield, 120° field of view

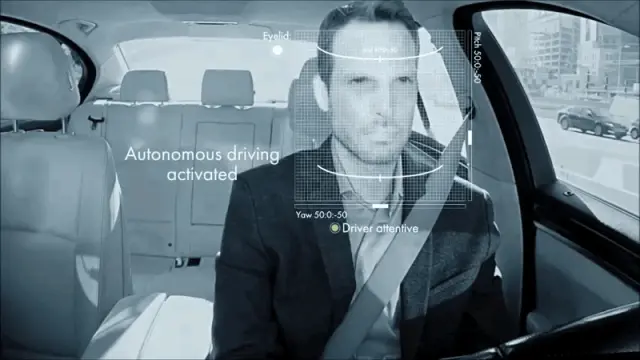

2. Driver Monitoring System (DMS) Camera

• Function: Tracks driver facial expressions and behavior to detect fatigue or distractions (e.g., mobile phone use)

• Features: Infrared night vision for 24/7 monitoring; AI algorithms analyze blink rate, head pose, and other biometric indicators

• Installation: Near the A-pillar or rearview mirror, facing the driver

3. 360° Panoramic Surround View System

• Function: Combines images from 4–6 wide-angle cameras to create a complete vehicle surround view and eliminate blind spots

• Features: Real-time image stitching with low latency; special algorithms to counter reflections and dust interference

• Installation: Four corners of the vehicle (standard configuration)

4. Rear/Reverse Camera

• Function: Provides high-definition reversing images for precise backing and loading operations

• Features: Wide-angle lens, automatic night enhancement; waterproof and shockproof design

• Installation: Vehicle rear or rear bumper

5. MDVR Main Controller (Mobile DVR)

• Function: Centralizes camera management, video recording, and AI analysis

• Features: Industrial-grade design with -20 °C to 70 °C operating range; supports 4G/5G/WiFi communication

• Storage: Dual TF card or hard drive redundancy, 512 GB–2 TB capacity

6. GPS/BeiDou Dual-Mode Positioning Module

• Function: Provides high-precision location data with geofencing and route tracking

• Features: Centimeter-level accuracy (with RTK); anti-multipath design for complex signal environments

• Update rate: Adjustable 1–10 Hz for stable tracking in dynamic conditions

7. Sensor Integration Interface

• Function: Connects to the vehicle CAN bus and other sensors to obtain speed, fuel level, tire pressure, and more

• Features: Standardized protocol support with scalability for various mining equipment sensors

Core Functional Features

1. Advanced Driver Assistance Systems (ADAS)

• Forward Collision Warning (FCW): Detects vehicles or obstacles ahead and warns of potential collisions

• Lane Departure Warning (LDW): Alerts when the vehicle unintentionally departs from its lane

• Headway Monitoring (HMW): Calculates safe following distance and alerts when too close

• Blind Spot Detection (BSD): Monitors sides and rear blind spots and provides warnings

2. Driver State Monitoring (DSM)

• Fatigue Detection: Identifies drowsiness based on eye closure frequency and head movements

• Distraction Recognition: Detects mobile phone use, smoking, and seatbelt violations

• Attention Assessment: Evaluates driver focus and suggests rest if needed

• Identity Verification: Facial recognition ensures only authorized personnel operate the vehicle

3. Panoramic and Blind Spot Monitoring

• 360° Seamless View: Provides complete surroundings during low-speed driving and reversing

• Dynamic Angle Switching: Automatically highlights areas based on turn signals

• Obstacle Detection: Identifies and marks ground obstacles during parking or low-speed operation

• Transparent Chassis View: Combines multiple camera feeds to display the road beneath the vehicle

4. Real-Time Video Analysis and Alerts

• AI Behavior Analysis: Detects risky driving behaviors and issues real-time alerts

• Event-Triggered Recording: Automatically saves 30 seconds of video before and after abnormal events

• Remote Live View: Managers can view inside and outside the vehicle in real time via mobile devices

• Multi-View Monitoring: Displays multiple cameras and vehicles simultaneously for centralized supervision

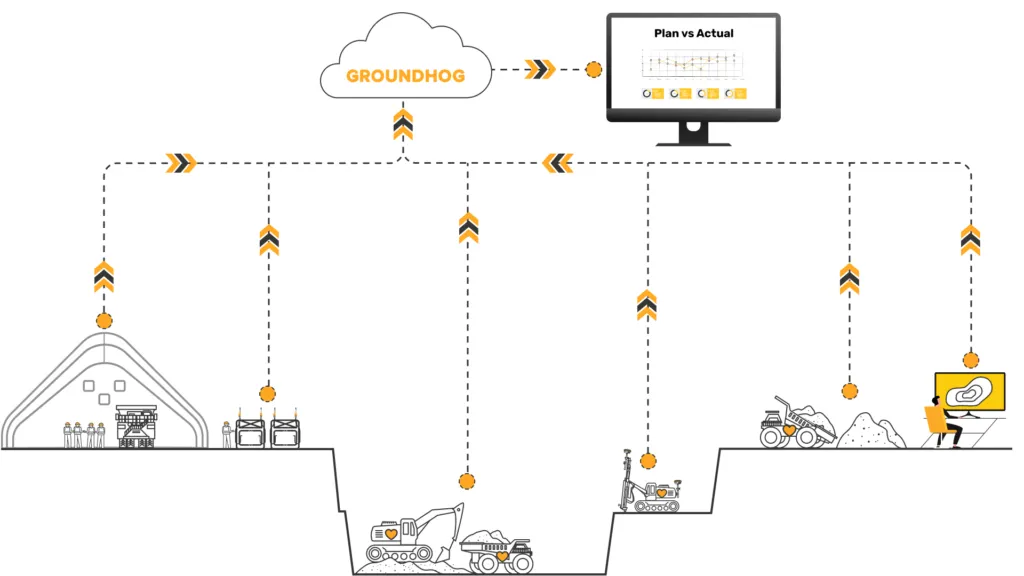

5. Fleet Management and Dispatch

• Real-Time Tracking: GPS/BeiDou dual-mode positioning for precise vehicle locations

• Geofence Management: Defines work zones and restricted areas with automatic alerts for boundary breaches

• Route Optimization: Plans optimal routes based on real-time traffic and operational needs

• Performance Analysis: Evaluates driver and vehicle efficiency using operational data

6. Data Security and Remote Management

• End-to-End Encryption: Secure transmission of video and location data

• Tiered Access Control: Different management levels access different data scopes

• Remote Firmware Upgrades: Update system software without on-site intervention

• Breakpoint Resume: Local storage during network outages with automatic upload upon recovery

Pilbara-Specific Adaptations

YUWEI’s system is specially optimized for the Pilbara environment:

• Extreme Temperature Tolerance: Hardware operates from -30 °C to 85 °C, handling summer heat and winter cold

• Dust Protection: IP69K-rated enclosures prevent dust intrusion

• Glare Suppression: WDR technology mitigates intense sunlight and glare

• Vibration Resistance: Reinforced design and shockproof mounting withstand continuous vibrations on rough terrain

• Solar Power Option: Supports solar-assisted power supply for remote areas with limited electricity

System Implementation and Benefits

YUWEI’s Pilbara deployments typically follow three stages:

1. Needs Analysis & Custom Design

• Assess mine-specific requirements, fleet size, and operating environment

• Design optimal camera layouts and system configurations

• Plan network infrastructure and data management solutions

2. Hardware Installation & System Integration

• Professional installation of cameras and equipment

• Integration with existing TMS (Transportation Management System) and MES (Manufacturing Execution System)

• Staff training and safety procedure development

3. Operational Optimization & Continuous Improvement

• Adjust system parameters to match actual operating patterns

• Regular maintenance and hardware checks for reliability

• Data-driven analysis to continuously improve safety strategies

Mines in the Pilbara interested in YUWEI’s mine truck camera system can contact YUWEI engineers. On average, the system achieves a 40–60% reduction in accidents, a 10–15% improvement in fuel efficiency, a 15–25% decrease in overall operating costs, and significant improvements in safety compliance and management efficiency.