Canadian Mining Truck Camera System Fleet Management

Canadian Mining Truck Camera System

In the Canadian mining industry, the efficient management and safe operation of mining truck fleets (statistically, over 5,000 heavy-duty mining trucks are in operation across Canada) are crucial to ensuring stable resource extraction and transportation. Faced with harsh environments, complex terrains, and communication challenges, traditional management methods are no longer sufficient for modern mining needs.

Challenges in Managing Canadian Mining Truck Fleets

Canadian mining truck fleets include heavy trucks, excavators, loaders, and other machinery, operating in harsh natural environments and complex terrains. Mining sites are often located in remote areas with insufficient communication network coverage, especially in underground mines where satellite and mobile signals are weak, making vehicle positioning and data transmission difficult.

Additionally, mining truck fleets face:

- Positioning difficulties: Underground mines lack GPS signals, and open-pit mines experience multipath interference affecting accuracy.

- Safety risks: Driver fatigue and distraction can easily cause accidents, and blind spots increase collision risks.

- Low efficiency: High empty-run rates and untimely dispatch reduce transportation efficiency.

- Management difficulties: Equipment maintenance is challenging, data is scattered, and operational optimization is hard to achieve.

Mining Truck Camera System and Fleet Tracking Management

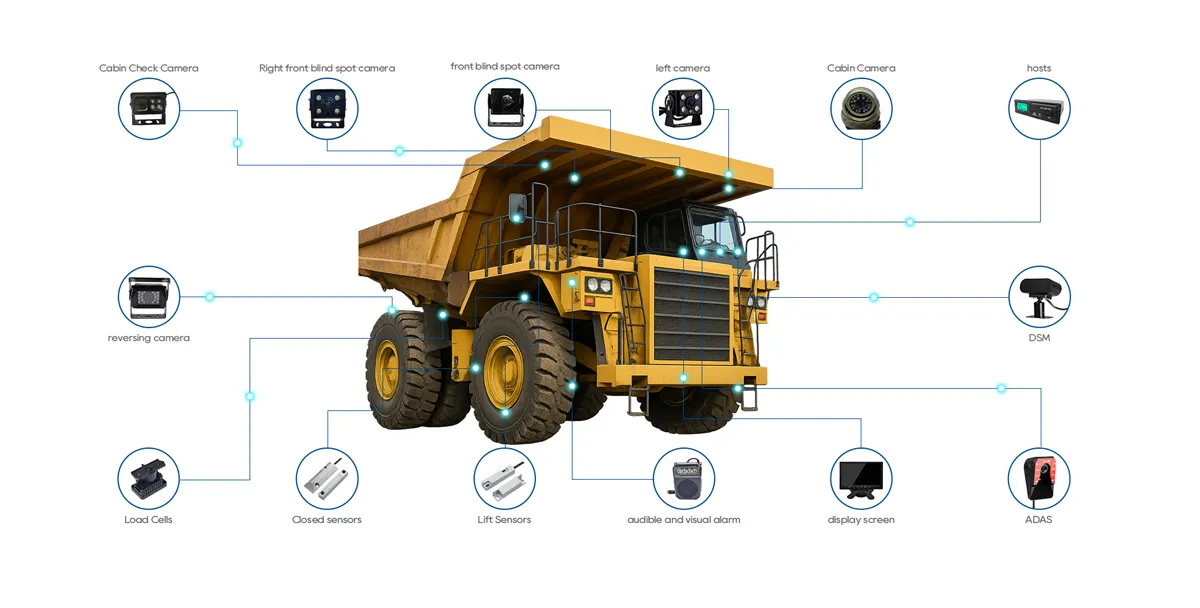

YUWEI’s solution integrates high-definition cameras, GPS positioning, ADAS-assisted driving, and other technologies to provide:

1) Real-time monitoring: 1080P HD cameras eliminate visual blind spots

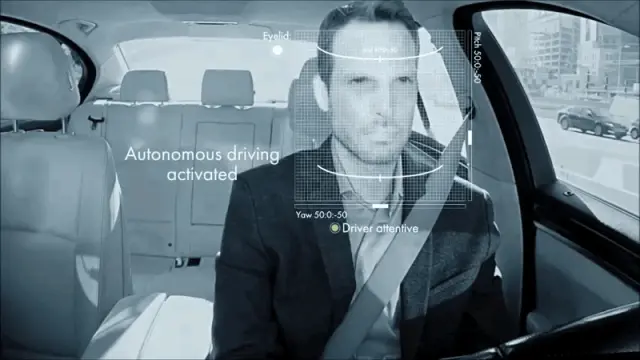

2) Safety alerts: ADAS monitors lane departure and front vehicle collisions; DMS monitors driver fatigue

3) Intelligent dispatching: Real-time GPS positioning optimizes routes and reduces empty-run rates

4) Data analysis: Records vehicle data to optimize maintenance and energy management

Advantages of YUWEI Mining Truck Camera System

1. Hardware Components

1) HD Cameras: 1080P panoramic + 360° surround view, monitoring without blind spots

2) ADAS & BSD: Forward collision warning, blind spot detection, lane keeping

3) DMS Driver Monitoring: Detects fatigue, distraction, and mobile phone usage

4) MDVR & GPS: 4G video storage, Beidou/GPS dual-mode positioning

5) Audible and Visual Alarms: In-cab buzzer + external warning lights for danger alerts

2. Core Functions

1) Real-time positioning: GPS/BDS precise tracking, electronic map displays vehicle status

2) Intelligent alerts: Automatic alarms for overspeeding, harsh braking, and lane departure

3) Driver monitoring: AI identifies fatigue driving and distracted behaviors

4) Efficient dispatching: Dynamically adjusts routes to reduce waiting and empty runs

5) Data management: Records transportation volume, fuel consumption, and optimizes operations

Why Choose YUWEI?

1) Adapted for harsh environments: Dustproof and waterproof, suitable for Canadian mines

2) Flexible customization: Supports both open-pit and underground mine requirements

3) Global deployment: Successfully applied in Canada, Australia, and other countries