Port Forklift Fleet Management

Port Forklift Fleet Management System

In warehouses, distribution centers and manufacturing plants, forklift fleets are the core of logistics operations. However, the lack of effective management can trigger a series of problems. YUWEI Forklift Fleet Management System accurately addresses these pain points with advanced technologies and comprehensive functions.

Core Challenges in Forklift Fleet Management

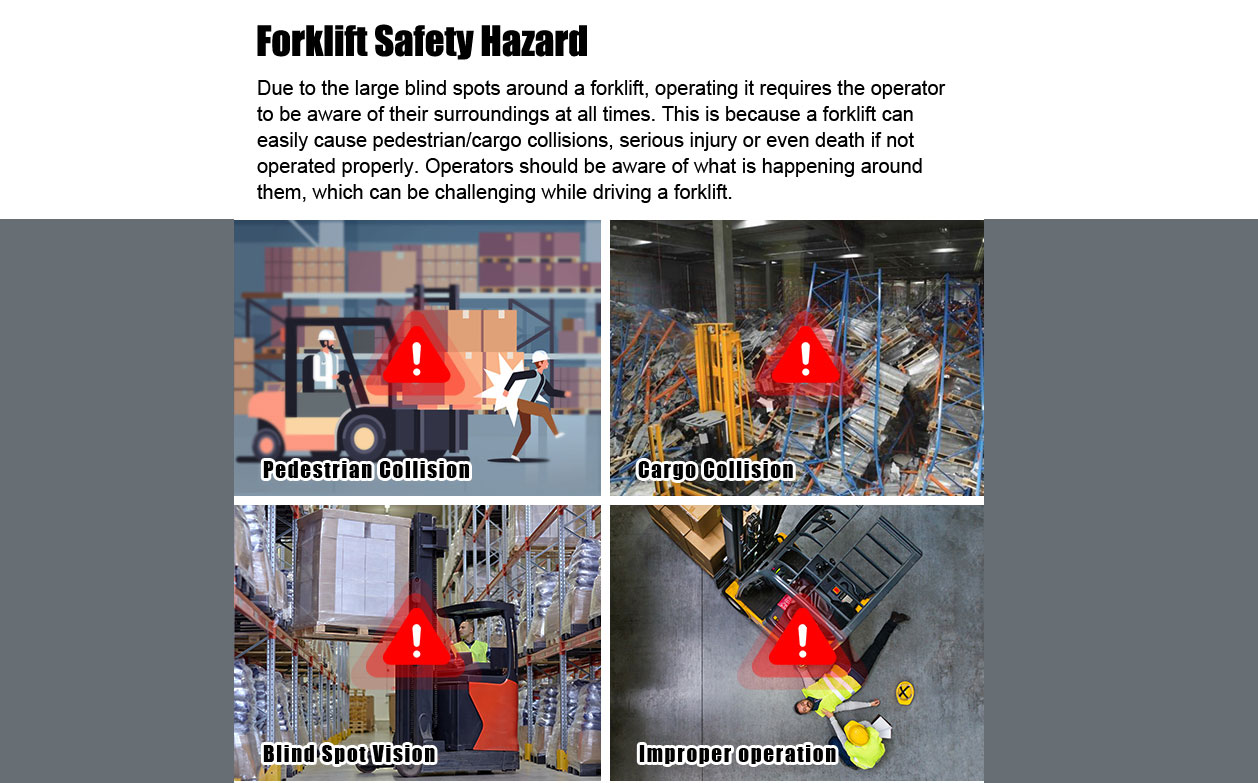

1. High Accident Costs

According to OSHA data, there are approximately 85,000 forklift-related accidents in the United States each year, resulting in casualties and millions of dollars in losses. Large blind spots of forklifts and distracted operators are the main causes. Improper operations are prone to collisions, while operators struggle to monitor the surrounding environment in real time.

2. Low Operational Efficiency

Studies by NITL show that 30% of forklift working hours are wasted due to unreasonable routes, vehicle searching or idling, which drags down logistics efficiency.

3. Chaotic Asset Control

The lack of real-time location and status monitoring of forklifts leads to unordered scheduling, low utilization rate, and risks of theft, resulting in significant annual losses.

4. Severe Maintenance Lag

Without accurate usage data support, preventive maintenance is difficult to implement. Forklifts suffer frequent unexpected downtime, and maintenance costs continue to rise.

YUWEI Forklift Fleet Management System

YUWEI Forklift Telematics & GPS Tracking System integrates hardware and software to provide data support, actionable insights and active safety protection, comprehensively improving the safety, visibility and efficiency of forklift operations.

1. Core Hardware Configuration

① Forklift Rear-View Camera: High-definition and waterproof, eliminating reversing blind spots and enhancing operational safety in narrow spaces.

② High-Brightness On-Board Display: Real-time display of panoramic images, operation prompts and alarms, providing intuitive guidance for operators.

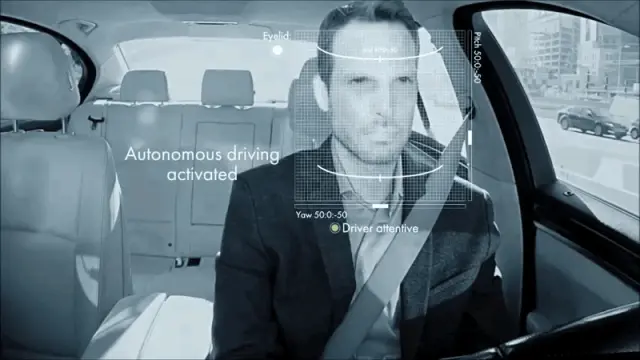

③ AI-Powered Mobile Digital Video Recorder (MDVR): Integrated with AI algorithms, ADAS and DMS, supporting 1080p full HD recording to capture detailed operational data.

④ Driver Monitoring System (DMS) Camera: Detects operator fatigue, distraction and irregular operations, and issues instant alarms.

⑤ Advanced Driver Assistance System (ADAS): Provides forward collision warning and lane departure warning to prevent accidents.

⑥ Optional 360° Panoramic Camera: Delivers blind-spot-free bird’s-eye view, ensuring safe and precise operations in complex environments.

⑦ Audio-Visual Alarm: Triggers instant alarms when hazards are detected to warn surrounding personnel.

⑧ Optional Intercom System: Enables real-time communication between forklifts and the dispatch center to improve collaboration efficiency.

2. Intelligent Software Management Platform

① Real-Time GPS Tracking: Accurately monitors forklift location, trajectory, speed and operating status on the map.

② 1080p HD Real-Time Video Monitoring: Allows remote viewing of real-time forklift images through terminals to keep track of on-site conditions.

③ Real-Time Alarm Notifications: Covers safety and equipment-related alarms, enabling managers to respond immediately.

④ Comprehensive Data Collection: Gathers data such as engine performance, operating hours and energy consumption to analyze the performance of forklifts and operators.

⑤ Massive Cloud Storage: Securely stores various types of data and supports conditional retrieval to meet auditing and investigation needs.

⑥ In-Depth Report Analysis: Generates detailed reports on vehicles, operators and maintenance to assist decision-making.

⑦ Geofencing Function: Sets virtual boundaries to trigger automatic alarms when vehicles enter or exit specific areas.

⑧ Maintenance Management: Automatically generates maintenance reminders and records maintenance history to ensure the sound operation of forklifts.

Email:hello@yuweitek.com