Best Blind Spot Detection & Monitor Installation Guide

Blind Spot System Installation

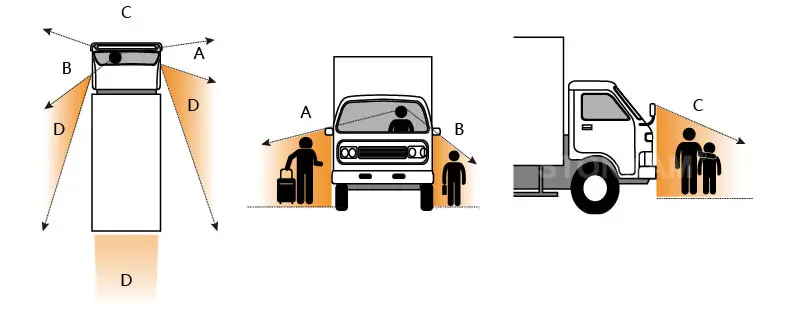

Vehicle blind spots are a major hidden danger to road traffic safety. For commercial fleets (logistics trucks, passenger buses, trailers, etc.), the risk is even greater: blind spots in large vehicles are 3–5 times larger than those of passenger cars, covering adjacent lanes, rear, and both sides. Multi-vehicle coordination and complex road conditions (highways, urban-rural roads) further increase the probability of accidents. Even with mirror adjustments, blind spots cannot be fully eliminated. Aftermarket blind spot sensors can monitor blind spots in real time, significantly improving driving safety and efficiency. This guide analyzes installation, selection, maintenance, and customized management based on the needs of commercial fleets.

Aftermarket Blind Spot Sensors

The aftermarket blind spot sensor market is mature. With strong compatibility and cost-effectiveness, they are an efficient choice for fleet safety upgrades:

① Cross-vehicle compatibility: Supports light trucks, heavy trucks, trailers, buses; some systems offer modular extensions (e.g., adding sensors to cover longer trailer blind spots).

② Cost control: Bulk procurement + low per-vehicle cost is more economical than OEM systems (which are usually standard only on high-end models).

③ Complex scenario compatibility: Some systems support “heavy vehicle mode,” filtering out road interference (shoulders, guardrails) and focusing on real risks (cars, pedestrians).

Aftermarket Blind Spot Sensor Installation Steps

Installation is simple and can be completed by non-technical users. Below is a general process (using a heavy truck as an example), with notes for fleet-specific needs.

Required Tools

Measuring tape, cleaning cloth, alcohol cleaner, marker pen, ladder (for high-position bumper installation).

Installation Steps

1. Measurement & Positioning: Mark sensor installation points on the bumper (including trailer connection). Heavy trucks must cover the right blind spot, 5m rear, and trailer blind spots.

2. Surface Cleaning: Clean marked areas with alcohol (important for heavy trucks prone to mud buildup).

3. Mark Fixing Points: Indicate sensor and magnet (or drill hole) positions; trailers require extra extension markings.

4. Temporary Fix & Test: Attach magnets at a 20° angle, simulate lane change/turning scenarios, confirm accuracy, then remove.

5. Sensor Installation: Attach sensors at marked points (screws recommended for heavy trucks to prevent vibration loosening).

6. Warning Device Installation: Stick LED warning lights to the driver’s right A-pillar or side mirror (adjust to driver’s line of sight).

7. Wiring & Debugging: Connect wiring per manual (wireless systems simplify this step); start the vehicle and test sensitivity (focus on lane changes, turns, and trailer blind spot alerts).

Fleet Notes

① Bulk installations should be uniformly calibrated (detection range, alert thresholds) to avoid inconsistent false alarms.

② Trailers require additional extension sensors linked with the main system (high-end systems support tractor–trailer linked alerts).

③ Fleets with mixed brands/models should choose multi-protocol compatible systems to reduce management complexity.

How to Choose the Best Aftermarket Blind Spot Sensor

When evaluating, consider the following criteria with a focus on commercial fleet use:

1. Detection Range & Accuracy

① Passenger cars require ~3m.

② Heavy trucks and buses need 5–10m coverage with multi-target recognition (cars, pedestrians, bicycles).

③ Trailer applications require long-range sensors (≥15m) to cover rear and side blind spots.

2. Anti-Interference Capability

① Must resist electromagnetic interference (from truck electrical systems or charging stations).

② Must meet IP67 waterproofing and function in -40°C to 85°C conditions.

3. Ease of Installation & Maintenance

① Choose quick-install systems (no drilling, magnetic mount), ≤30 minutes per vehicle.

② Prefer models with remote diagnostics (via OBD fault codes), minimizing downtime.

4. Integration with Fleet Management Systems

Smart sensors can upload blind spot data in real time, trigger automatic alerts for illegal lane changes or pedestrian detection, analyze accident-prone routes, and evaluate driver safety behavior for targeted training.

hnweb_

Aftermarket Sensors vs OEM Systems

Compared with OEM systems, aftermarket sensors offer:

① Flexibility: Support across multiple brands and vehicle types, whereas OEM systems are usually limited to specific models (heavy trucks often require customization).

② Cost-effectiveness: Aftermarket costs range from ¥2000–5000 per vehicle with bulk discounts, while OEM heavy truck systems often exceed ¥10,000.

③ Expandability: Aftermarket systems integrate with fleet platforms and support multi-target recognition, while OEM features are fixed and rely on manufacturer updates.

④ Maintenance Response: Third-party services are widely available with ≤24-hour repair time, whereas OEM repairs at dealerships often involve long queues and slow parts supply.

Aftermarket Blind Spot Sensor Maintenance

1. Calibration

① Single vehicles: First inspection after installation plus every 3–6 months.

② Fleets: Cross-calibrate 10% of vehicles after bulk installations using standard reflector boards.

2. Cleaning

① Wipe sensor surfaces every 2 weeks with alcohol.

② Clean bumpers at the same time to prevent dust interference.

3. Software Updates

① Individual vehicles: Update via mobile app or OBD.

② Fleets: Use bulk OTA updates for dozens or hundreds of vehicles at once.

4. Fault Troubleshooting

① Assign safety officers to check for loose sensors or abnormal indicator lights.

② Sign a rapid service agreement with providers for 4-hour response repair support.

Fleet Blind Spot Monitoring Management

Large-scale commercial fleets require tailored solutions and systematic management:

1. Fleet Blind Spot Risks

① Larger blind spots: right side 3m, rear 10m, left side 2m; trailers extend blind spots by 15m.

② More severe accidents: heavy trucks have braking distances ≥20m when unloaded, making collisions more dangerous.

③ Multi-vehicle coordination: lead vehicle lane changes can obscure following vehicle blind spots, leading to chain collisions.

2. Adapted Solutions for Fleets

① Layered coverage: tractors install main blind spot sensors (right, rear), trailers install extension sensors with wireless linkage.

② Tiered alerts: close range (≤3m) triggers sound, light, and vibration; mid-range (3–10m) triggers LED flashing.

③ Fleet coordination: using V2X technology, blind spot data from the lead vehicle is shared with following vehicles to prevent chain accidents.

3. Case Study

A logistics company with 200 heavy trucks installed aftermarket systems in 2024. Six months of data showed:

① Blind spot accident rate reduced by 67% (2.3 cases/month → 0.7).

② Emergency braking decreased by 42%, reducing tire and brake wear.

③ Fleet management optimized routes, avoiding three accident-prone areas and improving delivery efficiency by 8%.

Aftermarket blind spot sensors are an essential tool for achieving “zero-blind-spot operations” in commercial fleets. Their compatibility, cost advantages, and scalability make them ideal for large-scale and complex fleet operations. With tailored installation, systematic maintenance, and integration into fleet management systems, they can significantly reduce accidents, improve efficiency, and support the dual goals of safety and profitability.

Email:hello@yuweitek.com