Best Concrete Truck Camera Systems

Best Concrete Truck Camera Systems

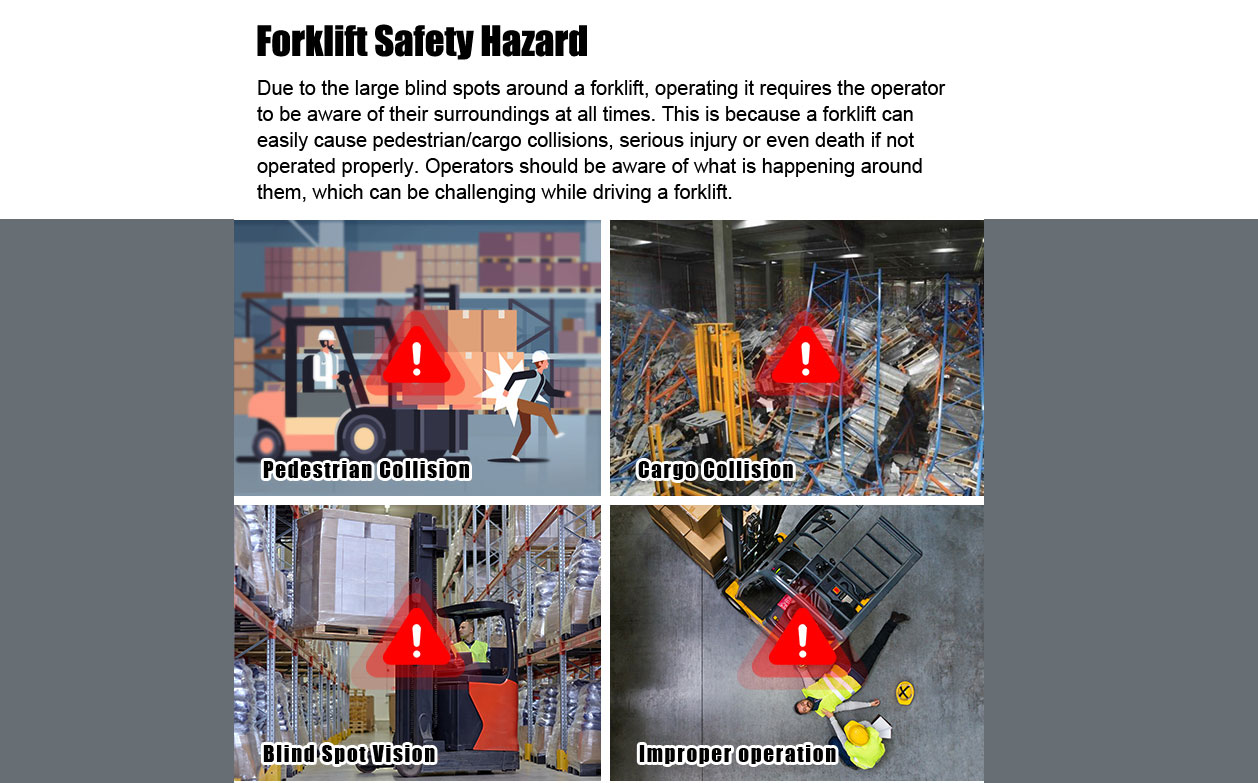

Concrete Truck Fleet is one of the vehicles with frequent accidents because of its large size, fast speed, and many blind spots; yuweitek developed this set of concrete truck camera systems based on the existing problems in the safety management of existing concrete fleets;

What problems does concrete truck camera systems solve?

1. Not following the prescribed route

2. Fatigue driving

3. Speeding

4. Pedestrian monitoring

concrete truck camera systems has the following functions

1. Intelligent video real-time monitoring

2. BSD detection of intelligent right blind spot

3. Forward and reverse

4. Load detection

5. Face DSM fatigue detection

6. LED display alarm function

7. Voice reminder for speeding and overloading

8. Sound and light alarm warning reminder

9. Monitoring center data report function

yuweitek concrete truck camera systems

YUWEI Concrete Truck Camera Systems is an intelligent and efficient solution system, which can ensure the safety of the fleet, reduce operating costs and establish a brand with scientific and modern management methods.

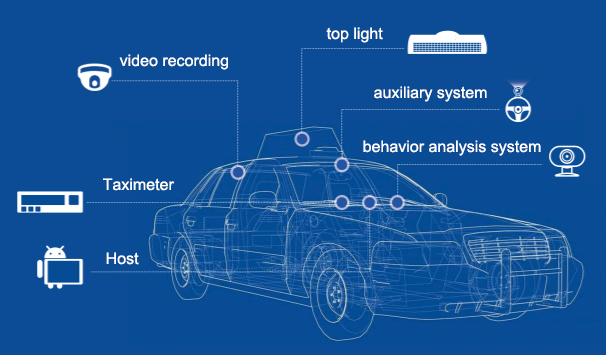

concrete truck camera systems is mainly composed of monitoring system cloud platform, vehicle positioning terminal, camera, forward and reverse sensor, oil rod, load sensor and so on. Monitor and dispatch commercial concrete trucks and pump trucks.

1. Real-time monitoring and real-time monitoring of the location of commercial concrete vehicles through Beidou/GPS positioning.

2. Monitor the reversing video of the commercial concrete car through the camera, and the right video can solve the visual blind spot of the right turn. The blind spot monitoring system can also be selected to realize the alarm of obstacles in the blind spot of the right turn.

3. It realizes real-time monitoring of the oil volume of the fuel tank, realizes key data such as oil leakage alarm, refueling data reporting, etc., ensures fuel safety, and correlates and compares it with driving mileage and forward and reverse time.

The forward and reverse sensors are used to monitor in real time whether the concrete tank of the commercial concrete truck is rotating forward, reverse or stopped. Combined with the driving status of the vehicle, it can be judged that the vehicle is in the process of transporting concrete, unloading, or empty; using edge computing forward and reverse sensors, not only calculates the rotation state, but also calculates the rotation speed, total rotation time, current state The duration and other data are all calculated.

The new angle load sensor is adopted to monitor the weight data in real time. Through the weight data, combined with the forward and reverse status, calculate the duration and weight of each unloading, combined with the electronic fence management of the customer's construction site, realize the alarm of illegal unloading, and calculate the unloading position, illegal unloading time, and unloading weight wait.

Combined with the electronic fence management function, through the time and status of commercial concrete vehicles entering and leaving the fence, an overtime alarm is issued to standardize the management of users (construction sites), provide the basis for settlement of overtime fees, and improve the management efficiency of all parties.

concrete truck camera systems realizes the functions of reversing image and right-turn blind spot image monitoring through on-board video, and the optional blind spot monitoring system realizes real-time reminder of right-turn obstacle alarm. Provide guarantee for the safety of commercial concrete truck transportation (driving, unloading process).