Concrete Mixer Truck Tracking Management System

Concrete Mixer Truck Tracking System

With the rapid development of urban construction, the concrete mixer truck industry is experiencing unprecedented business opportunities. At the same time, it poses certain challenges to the operation management of concrete mixer trucks and the transportation safety supervision by local governments. How to reasonably dispatch, improve vehicle utilization, reduce accidents during transportation, track fleet management in real-time, and provide comprehensive vehicle operation data reports are essential functions of a concrete mixer truck tracking management system.

Concrete Mixer Truck Management Challenges

Strengthening Government Supervision Needs

Preventing issues such as overloading, speeding, fatigue driving, violating restricted areas, and theft in concrete mixer trucks.

Intelligent Vehicle Operation Scheduling

High precision in vehicle positioning is required to ensure concrete mixer trucks can promptly arrive at target construction sites. Timely response is crucial, so accurate scheduling is essential for route optimization, rational dispatching, and cost savings in transportation.

Reducing Management Loopholes

Strengthening technical supervision measures against abnormal unloading and oil theft during transportation.

Enhancing Transportation Safety

Due to cost control by operating companies, drivers often experience fatigue driving and overwork. The large blind spots on the right and rear sides of mixer trucks increase the risk of traffic accidents. Additionally, the long body of the mixer truck makes it prone to rollovers during sharp turns.

Real-time Monitoring of the Drum

If the drum stops rotating, the concrete inside can solidify, making unloading and clearing cement faults time-consuming and labor-intensive. Therefore, the ability to monitor the drum’s working status in real-time is necessary.

Refined Management

How to use IT systems to manage the operation of concrete mixer trucks precisely, increase operational efficiency, improve business quality, and provide various operational data reports to support management and big data analysis.

Concrete Mixer Truck Tracking System Solution

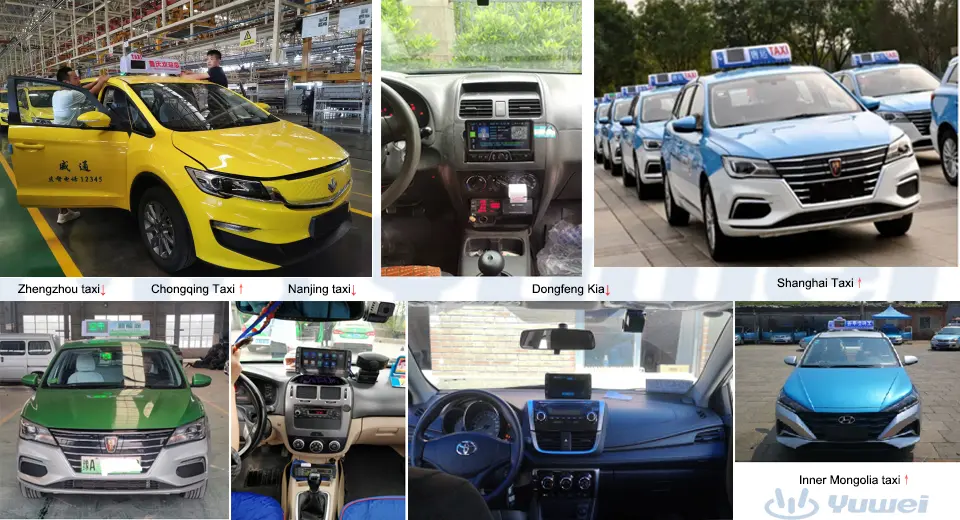

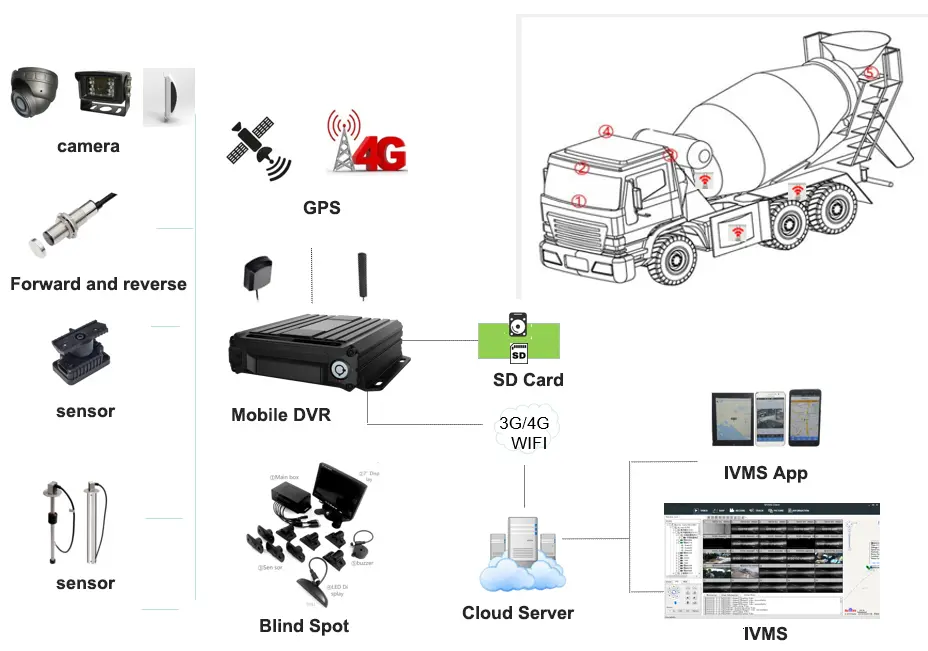

The YUWEI Concrete Mixer Truck Tracking System installs a 4G wireless video intelligent vehicle-mounted terminal kit to achieve high-precision GPS positioning, real-time audio and video dispatching, real-time oil level collection, forward and reverse drum status detection, blind spot radar detection and warning. By integrating a backend data monitoring cloud platform, it enables intelligent supervision and operational management of concrete mixer trucks. This solution has been successfully applied in many major cities in China.

Concrete Mixer Truck System Functions:

- Full-process Monitoring: Real-time video monitoring of vehicles allows remote viewing of each site situation and historical video data. The video screen dynamically switches to the corresponding position when the vehicle turns, providing driver assistance. High-precision GPS positioning enables real-time understanding of each vehicle’s location and current status, and historical travel routes can be retrieved.

- Visual Dispatching: Automatic vehicle queuing, displaying the status of dispatched vehicles en route to each construction site in a straight line simulation. This allows for clear visibility of vehicle conditions at construction sites, with flexible dispatching between stations. Standardizing the dispatch process improves vehicle utilization.

- Full-process Management: Clear visibility of dispatch time, transportation time, site stay time, waiting for unloading time, unloading time, and return time.

- Refined Fuel Management: Transparent display of the entire fuel consumption process, timely alarms for abnormal consumption, theft prevention, and report output for volume and per 100 kilometers fuel consumption data.

- Drum Status Monitoring: Real-time reporting of the drum direction status by installing forward and reverse sensors on the drum, with immediate alarms for abnormalities to prevent abnormal unloading and concrete solidification inside the drum.

- Safety Driving Assistance System: The in-vehicle terminal’s built-in safety module monitors the driver's state (DSM system), such as yawning, closing eyes, smoking, making phone calls, drinking water, and looking around. It also provides forward collision warning (FCW), headway monitoring warning (HMW), and lane departure warning (LDW) through the advanced driver assistance system (ADAS).

- Vehicle Driving Status Detection: The unique GSensor algorithm in the vehicle terminal detects dynamic driving behaviors such as rapid acceleration, rapid deceleration, sharp turns, and rollover collision warnings.

- Blind Spot Detection: High-precision radar sensors installed on the right and rear sides of the vehicle provide blind spot detection and warnings, reducing traffic accidents during vehicle travel.

- Data Statistics: Attendance reports, operation reports, and alarm reports.

- Information Management: Basic information management, vehicle maintenance information, and maintenance records.

YUWEI is a Chinese manufacturer, wholesale supplier of concrete mixer truck camera management systems, offering high quality and competitive prices. Welcome to purchase.

More:Fleet Vehicles GPS Tracking | best Rear Dash Cam | Turcker Dash cam with GPS tracking