Dump Truck Fleet Management System

Dump Truck Fleet Management

In the U.S. mining, construction, and logistics industries, dump trucks are core transportation assets.

According to the National Mining Association (NMA) 2024 data, more than 50,000 dump trucks are in operation in the U.S. mining sector alone, handling over 65% of the nation’s bulk material transportation annually.

However, as fleet sizes grow, low operational efficiency, frequent safety incidents, and uncontrolled fuel costshave become the top challenges for fleet managers.

Traditional management methods—relying on manual inspections and experience-based scheduling—struggle to meet the demands of modern fleet operations.

The integration of dump truck fleet management systems with telematics and GPS tracking is emerging as a critical solution for cost reduction and performance optimization.

Challenges in U.S. Dump Truck Fleet Management

The Federal Motor Carrier Safety Administration (FMCSA) reported in 2023 that 70% of dump truck accidents are directly caused by human error, and over 40% of these could have been avoided with real-time monitoring and alerts. Fleets without telematics systems incur additional annual losses averaging 12% of revenue, primarily due to:

1. Safety Management Failures

A single serious dump truck accident costs approximately $150,000 in direct expenses (repairs, compensation, downtime) and more than $500,000 in indirect costs (reputation damage, insurance premium increases). Traditional “post-incident” accountability methods lack real-time monitoring for risks such as fatigue driving, distracted driving (e.g., mobile phone use), and speeding, resulting in persistently high accident rates.

2. Fuel Cost Waste

Fuel accounts for 25–30% of dump truck operating expenses. Poor route planning and inefficient driving habits—such as rapid acceleration or harsh braking—cause an average waste of over 2,000 gallons (about 7,570 liters) of fuel per truck each year.

3. Low Dispatch Efficiency

Without real-time GPS tracking and vehicle status monitoring, dispatchers cannot accurately match tasks to vehicle locations. As a result, empty mileage averages 35%, and over 20% of operating time is spent waiting for loading or unloading.

4. Delayed Maintenance

Reliance on periodic maintenance schedules makes it impossible to adjust servicing based on actual vehicle conditions. Research by YUWEI shows that fleets without remote diagnostics experience over 40 hours of downtime per truck per year due to sudden failures of critical components like engines and transmissions.

YUWEI Dump Truck Fleet Management System

YUWEI has developed a comprehensive fleet management solution that combines high-precision hardwarewith full-scenario software, targeting the four key areas of safety, efficiency, cost control, and compliance. This system is designed to operate reliably under the extreme conditions faced by dump trucks, such as vibration, dust, and extreme temperatures, with all critical devices certified for FMCSA compliance.

Hardware Components

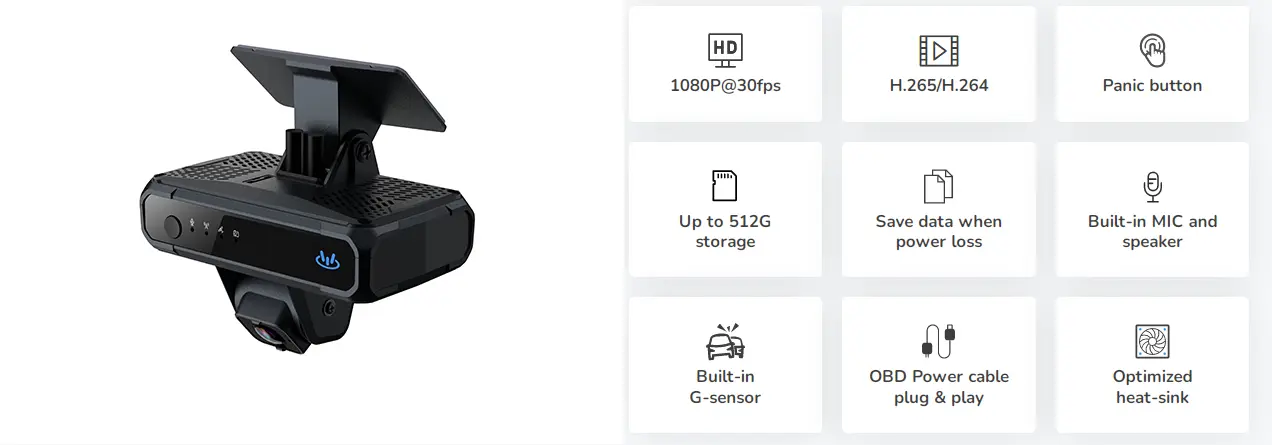

1. GPS-enabled AI Dash Cam– Equipped with ADAS and DMS, it detects fatigue (yawning, eyes closed for more than two seconds), distraction (mobile phone use, eyes off-road), and harsh driving behaviors. It triggers in-cab alerts and simultaneously reports to the backend in real time.

2. Mobile Digital Video Recorder (MDVR)– Stores up to four channels of 1080P video for 30 days, with collision-triggered auto-lock to preserve crucial footage. Supports 4G/5G remote video retrieval.

3. In-Vehicle Display– A 7-inch HD touchscreen showing navigation, alerts, and fuel data. Supports voice commands such as “Acknowledge alert” and “Show map” to reduce driver distraction.

4. Fuel Sensor– Uses electromagnetic technology with ±0.5% accuracy to track real-time fuel usage, generating fuel-saving driving reports.

5. Two-Way Radio & Audio-Visual Alarm– Provides instant fleet communication and triggers loud, visible alerts for overspeeding or fatigue driving, with simultaneous dispatch notifications.

6. Rear and 360° Cameras– Wide-angle rear view eliminates blind spots, while panoramic 360° imaging assists with precision maneuvering in tight mining environments.

Software Capabilities

1. Real-Time GPS Tracking & Route Playback– Updates every five seconds with ±5m accuracy; geofencing for restricted and work zones triggers automatic alerts; seven-day route history for performance review.

2. Live Video Monitoring & Cloud Storage– Allows remote viewing of live or recorded 1080P video, with AES-256 encrypted storage compliant with U.S. data privacy laws such as CCPA.

3. Intelligent Alerts & Tiered Response– Includes 12 preset alert categories (e.g., speeding, fatigue, harsh braking, route deviation) with severity-based notifications. Critical events, such as eyes closed for more than three seconds, trigger in-cab interventions.

4. Automated Reports & Analytics– Generates daily, weekly, and monthly reports covering fuel consumption trends, driver performance scores, and vehicle utilization metrics.

5. Telematics & Predictive Maintenance– Uses OBD data from the vehicle’s CAN bus (engine RPM, oil temperature, tire pressure) to predict faults like engine carbon buildup or brake wear, enabling proactive maintenance scheduling.

Case Study – Tangible Results

An Australian mining company operating 20 dump trucks faced frequent accidents (three per year) and fuel overspending of $12,000 per month. After implementing the YUWEI system for six months, the results were dramatic:

1. Safety– Fatigue and distraction incidents reduced by 65%, with zero liability accidents.

2. Cost Savings– Fuel consumption decreased by 18%, saving approximately $9,000 per month, while empty mileage dropped from 35% to 22%.

3. Efficiency– Dispatch times reduced by 40%, and each truck’s daily operating hours increased by 2.5 hours.

4. Compliance– Automated HOS logs ensured regulatory compliance, and environmental emissions met 100% of standards.

For U.S. dump truck fleets, telematics and GPS tracking have evolved from optional toolsinto essential survival systems. Leveraging China’s robust supply chain and proven global fleet deployments, YUWEI delivers a cost-effective, end-to-end solution—integrating industrial-grade hardware and adaptive software—to help fleets transition from safe operations to profitable growth.

I kept it in a professional whitepaper style without the table format, while still making it visually structured and readable.

If you want, I can next make this into a high-impact marketing copy versionthat’s punchier and more persuasive for sales presentations. That would make it even more client-facing.

Email:hello@yuweitek.com