Forklift Fleet Management in Northern Ireland

Northern Ireland Forklift Fleet Management

In the logistics park of Dublin Port, Ireland, more than 2,000 forklifts navigate between shelves every day. As a vital trade hub in Europe, Ireland has attracted global giants like Amazon and DHL to set up regional centers, thanks to its low tax rates, access to the EU Single Market, and an efficient logistics network. According to the Irish Central Statistics Office (2024), the annual output of the warehousing and logistics sector has exceeded €12 billion.

However, the era of "rough-and-ready" fleet management is becoming a critical bottleneck for local enterprises looking to upgrade. A study by the Irish Logistics Association (ILAA) found that 73% of medium-sized forklift fleets suffer annual losses exceeding €500,000due to inefficient dispatching, frequent accidents, and delayed maintenance—all stemming from the lack of digital management tools.

YUWEI's “Cloud-Based Forklift Fleet Management System + Telematics Solution”is addressing this gap through a comprehensive offering that combines hardware, cloud infrastructure, and localized services, optimizing the entire operational chain—from safety to efficiency—for both Irish and international fleets.

Forklift Fleet Management Challenges in Ireland

To understand the value of YUWEI’s solution, we must first face the real-world challenges Irish fleets encounter. Based on ILAA’s annual report and interviews with local enterprises, the absence of systematic management has revealed three major issues:

1. Safety Risks: Human Error Accounts for Over 60% of Accident Costs

As heavy-duty equipment in industrial settings, forklifts carry significant operational risks. According to Ireland’s Health and Safety Authority (HSA), in 2023, 82% of fleet-related accidents caused by driver fatigue, blind spots, or violations lacked real-time monitoring systems. These accidents could only be traced post-event via video playback. The average cost per incident—including downtime, compensation, and repairs—reached €87,000.

2. Inefficient Dispatch: The "Dead Mileage Trap" of Manual Assignment

Irish warehouses often feature multi-level or narrow-aisle designs that require highly accurate path planning. Yet, dispatchers still rely on paper tickets or basic Excel spreadsheets, leading to idle travel rates above 35%(compared to 28% in similar U.S. fleets). For example, one Dublin-based food warehousing company increased forklift daily handling capacity by 22%after implementing a digital management system.

3. Delayed Maintenance: Reactive Repairs Drive Up Costs

When critical components such as motors or hydraulic systems fail unnoticed, they can cause chain-reaction damage. Most Irish businesses adopt a “repair after failure” approach, resulting in unplanned downtime averaging 18%. Without tools to gather essential data (e.g., mileage, oil temperature, battery health), fleets spend 40% moreon annual maintenance compared to those using predictive systems.

YUWEI Forklift Fleet Management System

To meet the complex needs of the Irish and broader European markets—such as strict GDPR compliance, multilingual interfaces, and narrow-aisle compatibility—YUWEI has developed an integrated solution of "Hardware Terminal + Cloud Platform + Telematics Services."Its key advantage lies in lightweight hardware that collects full-spectrum data, with low-latency transmission to stable cloud servers in China, enabling real-time monitoring, intelligent dispatch, and predictive maintenance.

(A) Hardware Layer: 5 Components Form a Dual Line of Defense for Safety and Data

YUWEI’s hardware is purpose-built for challenging forklift environments (e.g., vibration, dust, lighting changes). Core components include:

1. Rear-View Camera (Waterproof)

Optimized for reversing scenarios, featuring a 180° wide-angle lens and F1.6 aperture. Rated IP67 for dust and water resistance, suitable for rainy outdoor use or cleanrooms. Low-light night vision (0.01Lux) ensures safe operation in darkness. Video data is uploaded in real-time for post-event analysis or driver training.

2. Onboard Display (Smart Info Terminal)

A 7-inch industrial-grade touchscreen supporting multiple languages (including English and Irish). Displays dispatch instructions, vehicle status (battery/fuel level, fault codes), and driver ratings. Anti-glare design aligns with forklift operating zones to minimize distraction.

3. DMS (Driver Monitoring System) Camera

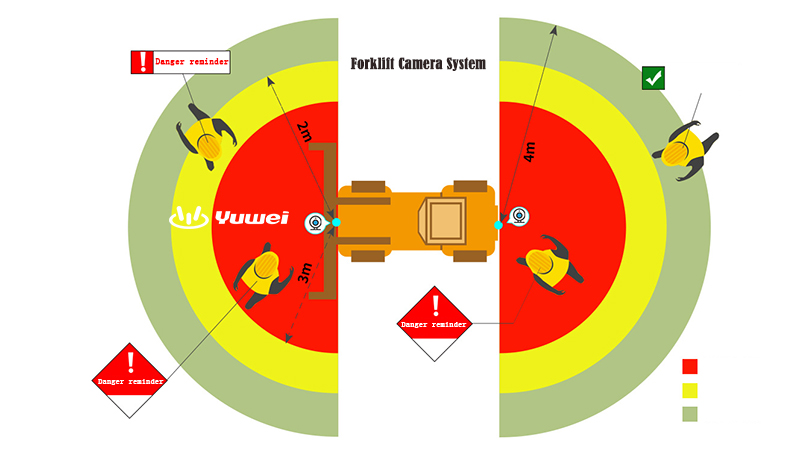

Uses AI to detect driver states such as eye closure, yawning, or phone use. Triggers audiovisual alerts and sends real-time warnings to managers upon detecting risky behaviors. EU EN 13491 certified, with a false alarm rate below 2%.

4. Audio-Visual Alarm Device

Combines a high-decibel buzzer and tri-color LED. Customizable alerts for overspeeding, restricted zones, or over-height cargo ensure risks are promptly noticed by drivers and nearby personnel.

5. MDVR (Mobile Digital Video Recorder)

Supports 4-channel input (expandable to 8), using H.265 compression to reduce storage without sacrificing quality. Built-in GPS logs vehicle position and routes, enabling integrated “driver-vehicle-route” analytics via the cloud platform.

(B) Cloud Platform: The Intelligent Brain from Data to Decisions

All data from the hardware (video, location, vehicle status, driver behavior) is transmitted via 4G/5G networks to YUWEI's cloud servers (AWS, Alibaba Cloud, and other global nodes supported). Managers can access the following features via desktop or mobile (iOS/Android):

1. Real-Time Monitoring Dashboard

Visualizes fleet status (online/offline vehicles, incident stats), individual vehicle locations, and playback of routes. Supports filtering by region and time.

2. Smart Dispatch Engine

Matches optimal forklifts and drivers based on historical operations, real-time orders, and current vehicle conditions (e.g., assigning high-capacity forklifts for heavy loads, prioritizing urgent orders). Reduces idle rates and boosts productivity.

3. Predictive Maintenance Alerts

Analyzes operational data (motor temperature, battery cycles, etc.) to forecast issues 7–15 days in advance (e.g., hydraulic fluid aging, brake wear), preventing unplanned downtime.

4. Compliance & Training Support

Automatically generates operation logs and incident reports that meet HSA standards. Combined with DMS behavior data, it offers personalized safety training (e.g., targeted courses for distracted drivers).

For more information on our forklift fleet management solutions, contact us at: