Germany Forklift Safety Management Solutions

Germany Forklift Management Solutions

The forklift safety management system is designed for global smart manufacturing environments and is also suitable for German factories, logistics parks, and high-end manufacturing enterprises.

Intelligent Systems · Coverage of Multiple Scenarios

Integrating German industrial concepts, YUWEI offers a range of high-performance safety management systems that cover the entire process of transportation and operations within enterprises:

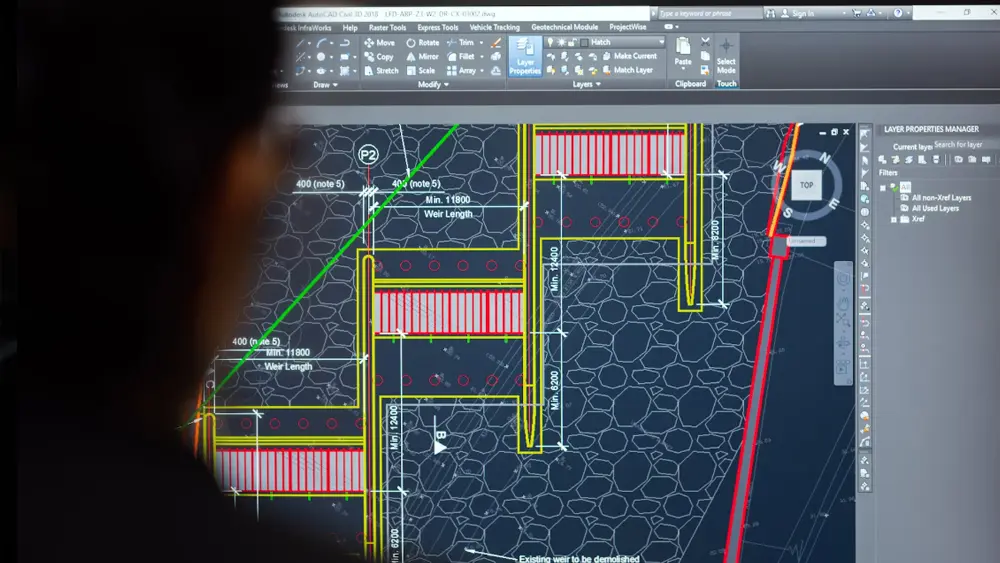

- Vehicle Blind Spot Visual System: Eliminates driving blind spots and enhances operational visibility.

- Onboard Intelligent Remote Monitoring System: Real-time monitoring in the background, providing clear insights into operations.

- Driver Fatigue Warning System: Detects fatigue driving, distractions, and phone usage.

- Vehicle Collision Prevention Warning System: Automatic sensing, early warnings, and accident prevention.

Product Series Overview

- Dual-Vision Blind Spot System

Suitable for small industrial vehicles, covering the critical front and rear areas.

- Four-Vision Blind Spot System

Provides 360° monitoring without dead zones, enhancing the vehicle’s perception capabilities.

- Four-Way Remote Management System

Uses industrial-grade cameras for remote high-definition video collection.

- Remote Intelligent Management Platform

Supports multi-vehicle network management, unified scheduling, and intelligent analysis.

Focus on Forklift Operations · Professional Safety Upgrades

YUWEI adopts German manufacturing standards to create exclusive monitoring systems for forklifts, addressing safety and management challenges during forklift usage:

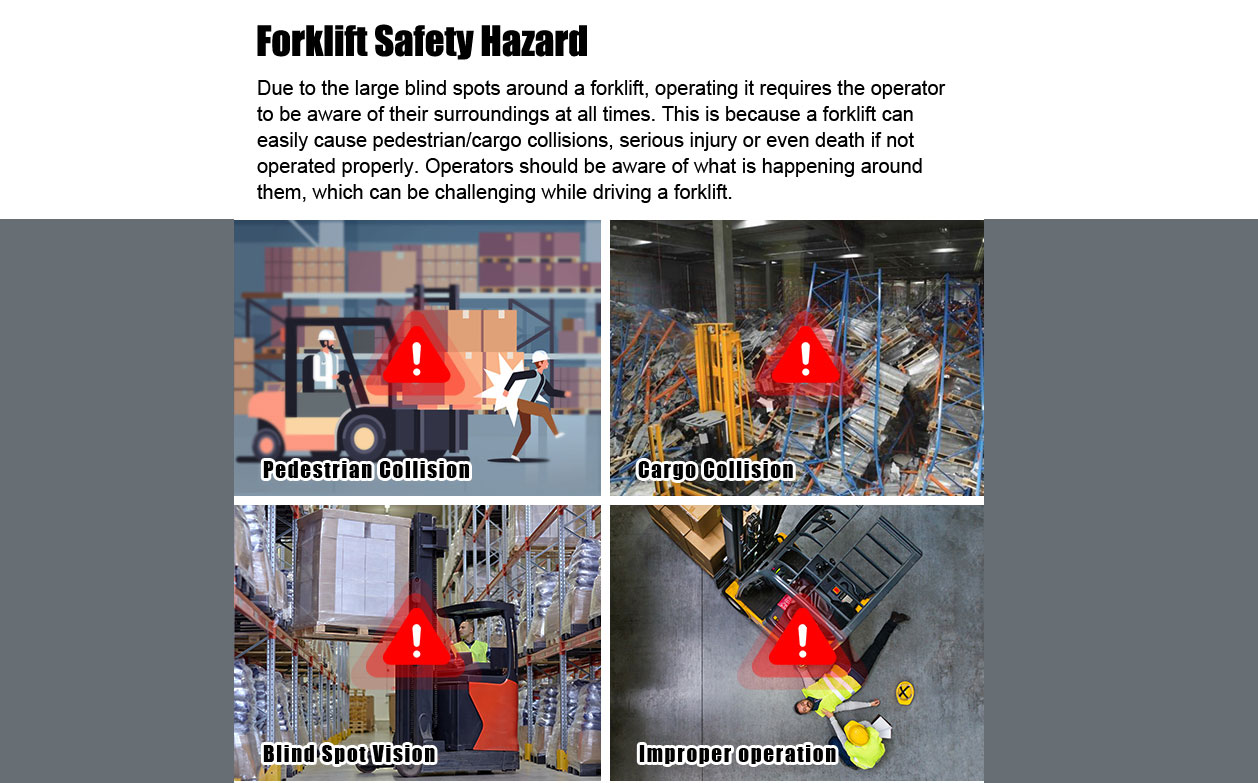

- Frequent Accidents: No monitoring of operations, making it hard to assign responsibility after incidents.

- Fatigue Driving: Lack of real-time supervision, making hidden dangers hard to control.

- Weak Management: Confused scheduling inside and outside the factory.

- Blind Spot Issues: Lack of visual records and traceability.

Solutions · Four Core Functions

1. Remote Video Real-Time Monitoring

Equipped with industrial 4G cameras, the system ensures stable transmission around the clock, allowing real-time viewing of operational conditions and improving scheduling transparency.

2. Online/Offline Time Statistics

The system automatically records the working hours of each vehicle, which can be checked throughout the process, providing accurate control over vehicle utilization.

3. Real-Time GPS Positioning

High-precision GPS modules dynamically monitor the vehicle's location, preventing it from straying from the operation area and enhancing scheduling efficiency and safety.

4. Video Playback and Historical Traceability

4G cloud storage supports full-process recording, and key moments can be restored with one click. Compliant with GDPR privacy regulations, providing a solid foundation for management.

The Value We Bring to You

- Efficient Scheduling

Get an overview of the entire vehicle status in one view, enabling flexible management and preventing resource idling.

- Standardized Operations

Video monitoring identifies rule violations, fostering the development of a safety culture.

- Safety Risk Control

Real-time warnings and positioning systems comprehensively reduce safety risks.

- Intelligent Record-Keeping

Every operational data point and frame of video can be queried and traced, supporting compliance management and clear accountability.