Haul Truck Dispatch System

Haul Truck Fleet Management System

In the complex production chain of modern open-pit mining — encompassing ore extraction, transportation, and processing — precision and coordination are critical. Safetyis the lifeline of mine operations, making the prevention of accidents and the protection of personnel and equipment essential.

At the same time, intense market competitioncompels mining enterprises to continuously optimize their production processes, reduce costs, and improve efficiency and resource utilization to remain competitive.

However, traditional open-pit mining operations face several pressing challenges:

Current Pain Points

1. Inefficient Dispatching

Manual, experience-based allocation of trucks and shovels leads to high idle rates, poor coordination, and low productivity.

2. Disorganized Equipment Management

Real-time equipment status is unavailable, fault warnings are delayed, and maintenance costs remain high.

3. Significant Safety Risks

Frequent violations such as speeding and boundary crossing, coupled with delayed environmental monitoring, greatly increase accident risks.

4. Severe Data Silos

Data fragmentation across multiple systems prevents scientific and data-driven decision-making.

5. Excessive Fuel Waste

Fuel theft, leakage, and aging equipment cause uncontrolled fuel consumption and cost escalation.

YUWEI Haul Truck Intelligent Dispatch System

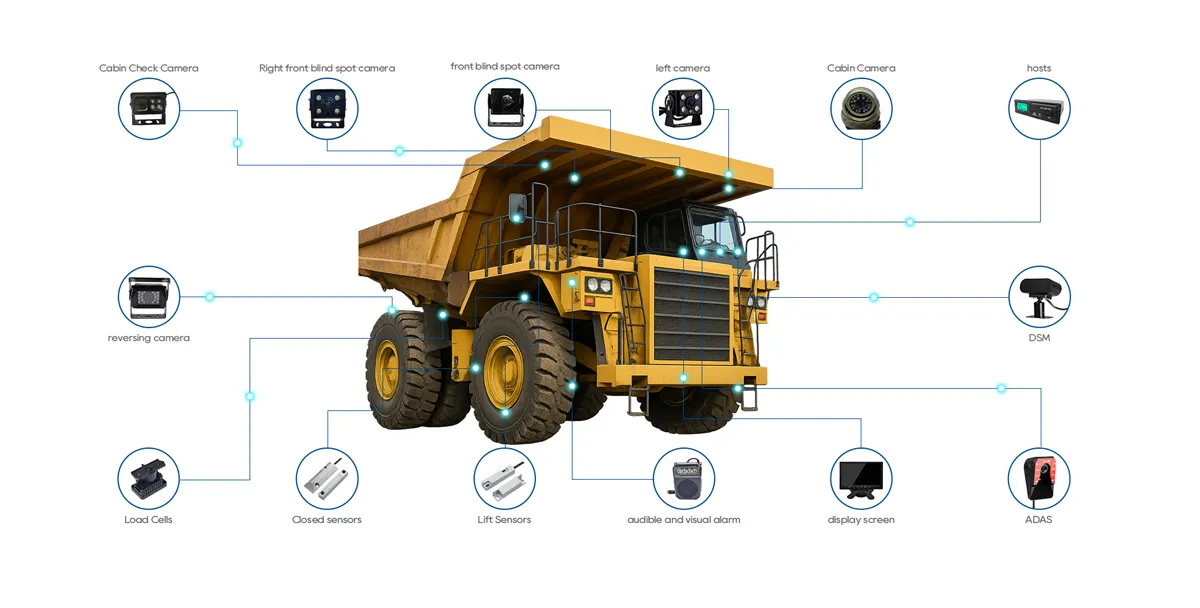

Powered by IoT, sensors, computer hardware, 3D laser scanning, and 4G/5G network communication, the YUWEI Haul Truck Intelligent Dispatch System builds an interconnected and data-sharing platform for mine business management, comprehensive dispatching, and production decision support.

It significantly enhances the intelligence level of open-pit mining operations, enabling high-efficiency, safe, and sustainable development.

Core Solution

Covering four major core scenarios — production dispatching, equipment management, safety monitoring, and energy consumption control— the system creates a complete intelligent mine management ecosystem.

1. Intelligent Dispatching

Based on ore blending plans, equipment conditions, and transport distances, the system generates daily/monthly production plans and dynamically matches shovels and haul trucks.

This greatly reduces idle driving time, optimizes resource allocation, and improves operational efficiency.

2. Equipment Maintenance

Electronic profiles are created for each piece of equipment, recording full lifecycle data from storage to retirement.

It supports maintenance records, service reminders, and spare parts management, fully replacing outdated paper-based methods.

3. Real-Time Monitoring

Through onboard terminals, the system collects real-time operational data (e.g., fuel consumption, engine speed).

Combined with big data analytics, it predicts wear trends, issues early fault warnings, and ensures timely maintenance.

Safety Monitoring

Driver Behavior Monitoring

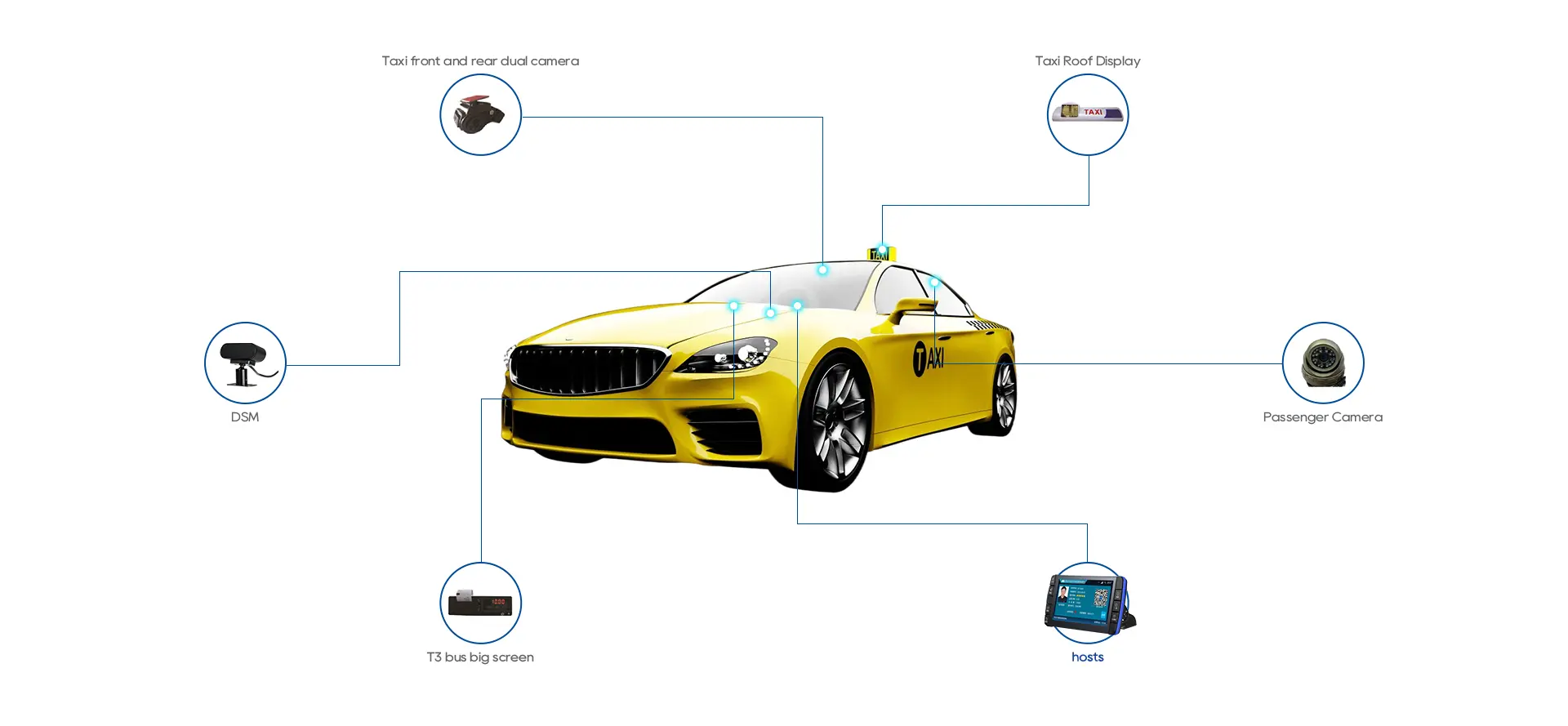

Using DMS cameras, the system analyzes driver status in real time to detect fatigue, phone use, speeding, and other violations.

It provides instant alerts and in-cab voice reminders, significantly reducing human-related accidents.

Environmental & Equipment Safety Alerts

The system integrates slope monitoring, dust/noise detection, and vehicle anti-collision functions.

It provides real-time alerts for boundary crossing, overloading, and environmental exceedances, ensuring comprehensive safetyfor both personnel and equipment.

Fuel Management

Intelligent Fuel Consumption Monitoring

High-precision sensors track fuel level changes in real time, generating detailed fuel reports.

This allows for precise identification of high-consumption equipment and abnormal leaks, supporting data-driven energy optimization.

Anti-Theft Protection

Features such as fuel tank opening alarmsand low-fuel warningseffectively deter fuel theft.

Optimized dispatching also reduces idling time, achieving energy savings and cost reductionfor the enterprise.

System Value

1. Intelligent Dispatching

Using truck dispatch optimization models based on ore blending requirements and current production capacity, the system achieves optimal route selection, global/local traffic planning, and real-time dispatching, ensuring smooth and efficient production flows.

2. Real-Time Dispatching

Trucks and excavators can be grouped for flexible management, with dispatch commands sent at any time.

In special situations, dispatch plans can be adjusted instantly.

Onboard terminals deliver voice prompts and visual instructions, ensuring accurate communication of dispatch orders.

3. Real-Time Monitoring

Tracks and displays the real-time position, speed, status, and routeof any truck or excavator within the mining area.

Provides speeding alertsand supports playback of historical operation trajectories for comprehensive equipment monitoring.

4. Zonal Alerts

Displays the current vehicle position, truck workload, and shovel loading data in real time.

The dispatch center can set alerts for speeding or boundary violations through onboard terminals, effectively mitigating safety risks.

5. Real-Time Statistics

Compiles data such as number of trips, output, operation time, mileage, and fuel consumptionby shift, generating detailed reports to support informed management decisions.

The YUWEI Haul Truck Intelligent Dispatch System, with its advanced technology, comprehensive functionality, and significant operational value, provides powerful support for mining enterprises to overcome traditional challenges and achieve intelligent transformation.

Email:hello@yuweitek.com