Mining Fleet Management Systems

Mining Fleet Management Solution

In the daily operations of open-pit mines, dump trucks are vital transportation tools, and their safety management has always been a significant challenge for enterprises. The complex terrain, harsh environment, and high-intensity operations make safety management for dump trucks particularly difficult. Today, let’s explore how YUWEI's mining fleet management system offers a new solution for enhancing safety management in open-pit mines.

What Are the Key Management Challenges of Dump Trucks?

Driver Fatigue and Operational Errors

In open-pit mines, dump truck drivers often face high-intensity workloads. Night driving and fatigue are common, leading to operational mistakes and potential safety accidents.

YUWEI Solution

The YUWEI intelligent dump truck monitoring system is equipped with an advanced fatigue warning system that uses AI algorithms to monitor the driver’s facial expressions and driving behavior in real-time. Once the system detects signs of fatigue, such as yawning or squinting, it sends a voice prompt to remind the driver to stay alert. Additionally, the incident is instantly uploaded to the cloud via 4G network, allowing remote monitoring and timely intervention by management.

Blind Spots and Pedestrian Safety

Due to the large size of dump trucks, there are significant blind spots, especially when reversing or turning, which increases the risk of accidents involving pedestrians or other vehicles.

YUWEI Solution

The YUWEI panoramic imaging system and blind spot pedestrian intrusion warning system provide comprehensive visual support for dump trucks. Cameras are installed on the front, rear, left, and right of the vehicle to create a 360-degree panoramic image, allowing the driver to monitor the surroundings in real-time. The system also issues an automatic warning if pedestrians or vehicles enter the blind spot, alerting the driver to take evasive action.

Low Vehicle Management Efficiency

Open-pit mines have vast operational areas, making vehicle dispatch and management challenging. Traditional management methods struggle to track the real-time location and operational status of vehicles, leading to inefficiencies in scheduling.

YUWEI Solution

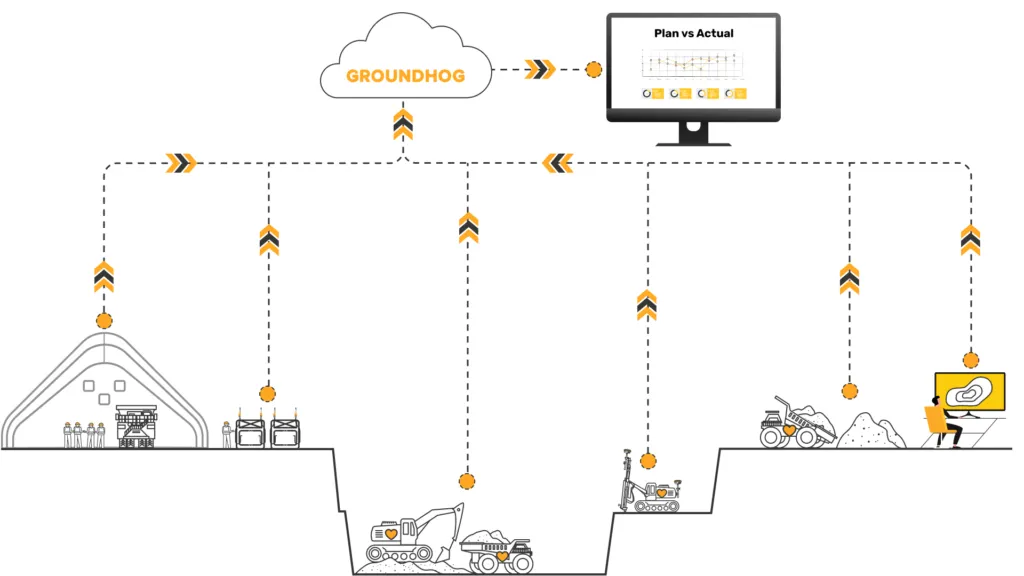

YUWEI's mining fleet management system enables remote monitoring via 4G networks, allowing management to view real-time information on each vehicle’s location, operational status, and work progress. The system also supports features like electronic fencing and route deviation alarms to ensure vehicles follow designated routes. Centralized platform management allows for efficient scheduling, improving vehicle utilization and operational efficiency.

Equipment Reliability in Harsh Environments

Open-pit mines present complex environments, with dust, mud, and high-pressure water cleaning placing extreme demands on dump truck equipment’s reliability. Traditional monitoring devices often fail in such environments, causing system malfunctions.

YUWEI Solution

YUWEI’s onboard monitoring devices are rated IP69K for waterproof and dustproof performance, preventing dust from entering and withstanding high-pressure, high-temperature water impacts. This ensures stable operation of the equipment, even in environments with high-pressure water cleaning and flying dust, greatly enhancing reliability and extending the service life of the equipment.

Applicable Scenarios

YUWEI's mining fleet management system is suitable for a variety of open-pit mining environments, including large-scale open-pit coal mines, metal mines, and non-metal mines. Through intelligent monitoring and management, the system not only improves safety levels but also reduces management costs and enhances operational efficiency.