Mining Truck Fleets GPS Tracking Solutions in Canada

Canada Mining Truck Fleets GPS Tracking Solutions

As a global mining powerhouse, Canada is home to a vast fleet of mining trucks. It is estimated that over 5,000 mining trucks—including dump trucks, articulated trucks, and more—are in active use across Canadian mining operations. Furthermore, Canada is accelerating the development of critical battery metals such as lithium, cobalt, and rare earth elementsto meet the growing demands of the clean energy sector. Mining contributes over 5% of Canada’s GDPand supports hundreds of thousands of jobs.

Challenges in Canadian Mining Transportation

Canada's mining transportation system faces a range of unique environmental and operational challenges:

1. Geographical and Environmental Factors

Mining sites are often located in remote areaswith harsh climates (extreme cold, snowstorms) and complex terrain, placing high demands on vehicle performance and tracking systems.

2. Challenges of Large-Scale Operations

Large mines often operate dozens or even hundreds of truckssimultaneously. Traditional manual dispatching is inefficient and fails to optimize resource allocation.

3. Safety Compliance Pressure

Canada enforces strict mining safety standards, requiring real-time monitoring of vehicle status and driver behavior to prevent accidents.

4. Cost Control Needs

Rising fuel costs, maintenance expenses, and labor spendingcall for intelligent solutions to improve efficiency and reduce operating costs.

5. Environmental Compliance

With increasingly stringent carbon emission policies, precise monitoring and management of fleet emissions are essential.

Core Technologies of Mining Truck Fleet Tracking Systems

Modern fleet tracking solutions integrate advanced technologies into a comprehensive intelligent management system:

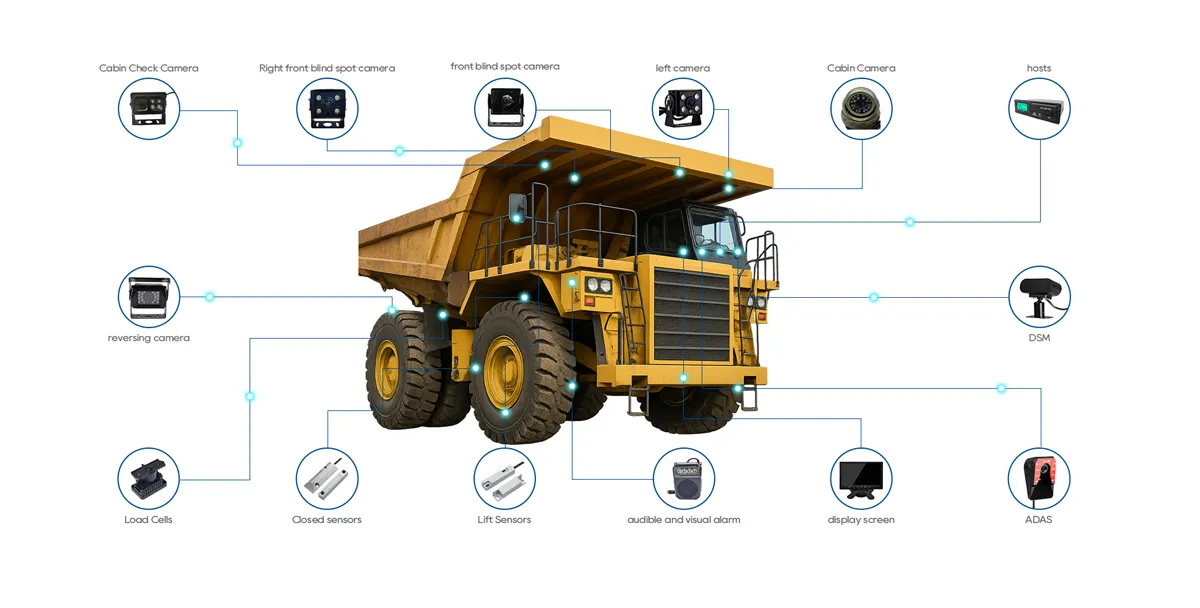

1. IoT and Sensing Technologies

a. Multifunctional Onboard Terminals: Equipped with GPS, accelerometers, gyroscopes, and other sensors to capture real-time data on location, speed, and payload.

b. Vehicle Health Monitoring: Retrieves key engine metrics, fuel consumption, and fault codes via OBD interfaces.

c. Environmental Sensors: Monitor external temperature, humidity, and road surface conditions.

2. Precision Positioning Technologies

a. Multi-Constellation GNSS: Uses GPS, GLONASS, and Galileo systems to deliver reliable positioning in remote areas.

b. Inertial Navigation Assistance: Ensures continuous tracking in GPS-denied environments such as underground mines or canyons.

c. Regional Augmentation Systems: Ground stations provide correction signals to achieve centimeter-level accuracy.

3. Wireless Communication Networks

a. Hybrid Networking: Combines satellite communication (for ultra-remote areas), 4G/5G cellular networks, and dedicated radio systems.

b. Edge Computing Architecture: Onboard terminals can process and store data locally when network coverage is poor.

4. Data Analytics and Artificial Intelligence

a. Machine Learning Algorithms: Analyze historical data to predict maintenance needs and optimize dispatching.

b. Computer Vision: Uses in-vehicle cameras to monitor driver behavior and surrounding environments.

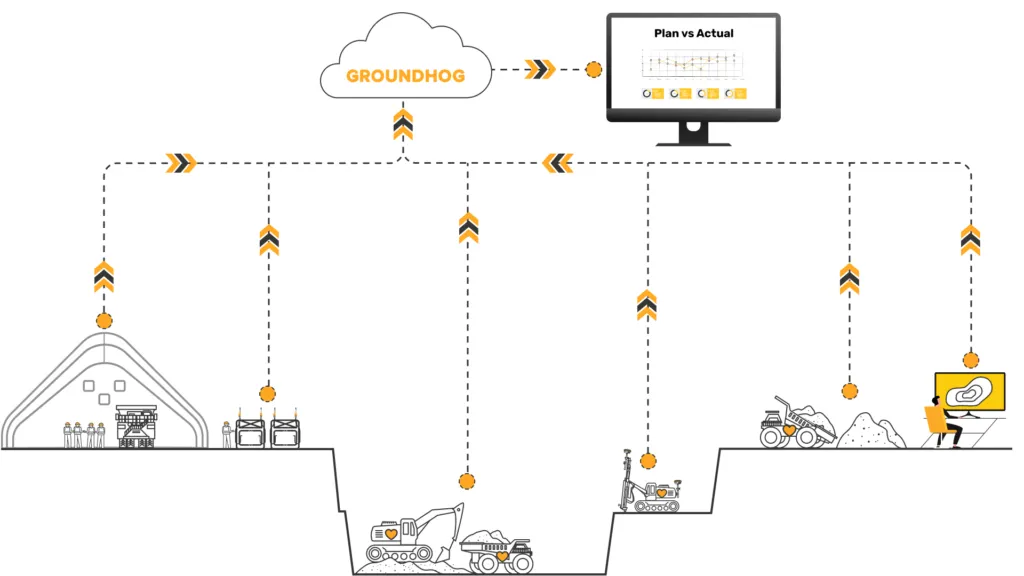

c. Digital Twin Technology: Builds a virtual model of the fleet for simulation and optimization.

5. Cloud Computing Platform

a. Distributed Data Storage: Handles massive volumes of vehicle data.

b. Real-Time Analytics Engine: Detects anomalies and responds within milliseconds.

c. Multi-Device Access: Supports monitoring via PC, mobile, and onsite command centers.

Functional Modules of the System

A complete mining fleet tracking system typically includes the following core modules:

1. Real-Time Tracking and Monitoring

a. Bird’s-eye view of the entire fleet and detailed tracking of individual vehicles.

b. Geofence setup and breach alerts.

c. Compliance checks for transportation routes.

2. Intelligent Dispatch Optimization

a. Dynamic task assignment based on real-time load and location.

b. Multi-objective optimization algorithms balancing efficiency and cost.

c. Rapid rescheduling in emergencies.

3. Maintenance Management

a. Predictive maintenance based on actual usage.

b. Maintenance history and lifecycle analysis.

c. Intelligent inventory management for spare parts.

4. Safety Management System

a. Driver behavior monitoring (fatigue, distraction, violations).

b. Collision warnings and emergency braking interfaces.

c. Automated speed control in hazardous zones.

5. Fuel and Emission Management

a. Real-time fuel consumption monitoring.

b. Idling time analysis.

c. Carbon emission calculation and reporting.

6. Operational Performance Analysis

a. Transport cycle time analytics.

b. Fleet utilization statistics.

c. KPI dashboards and automated reporting.

Recommended Solution: YUWEI Mining Fleet Management System

Among the many fleet management solutions in Canada, YUWEI Technologiesstands out for its local experience and advanced technology. Its one-stop smart tracking system is specifically designed to tackle Canada’s unique mining environment and operational demands.

Key Advantages of YUWEI's Solution

1. Extreme Environment Compatibility

a. CSA-certified hardware operates reliably from -50°C to 85°C.

b. IP68-ratedfor dust and water resistance, suitable for harsh mining conditions.

c. Anti-vibration designtailored to the rugged requirements of heavy mining trucks.

2. Hybrid Positioning Technology

a. GPS + GLONASS + BeiDoufor surface positioning, LBS + inertial navigation(YUWEI patent) for underground tracking.

b. Seamless switching between surface and underground modes.

c. Positioning accuracy: ±0.5m on surface, ±1.5m underground.

3. Localized Service Network

a. Service centers in key mining provinces: Alberta, British Columbia, and Quebec.

b. Bilingual technical support in English and French.

c. 24/7 emergency responsemechanisms.

4. Regulatory Compliance in Canada

a. Fully compliant with PIPEDA data privacy laws.

b. Meets Canadian Mining Safety Standards (CMSS).

c. Emissions module aligned with federal and provincial environmental regulations.

YUWEI System Highlights

1. Smart Dispatch Module

a. Real-time AI-driven dispatch algorithm.

b. Automatic route and load sequence optimization.

c. Priority handling for emergency tasks.

2. Safety Management System

a. Driver fatigue monitoringusing facial recognition.

b. Automatic speed control in hazardous zones.

c. Collision warning system with 150m front/rear monitoring.

3. Arctic-Specific Solution

a. Specially optimized for northern Canadamining operations.

b. Enhanced monitoring in polar night conditions.

c. Cold-start support systemfor extreme low temperatures.

4. Indigenous Community Collaboration Features

a. Special reporting for operations within Indigenous territories.

b. Alerts for community-sensitive zones.

c. Automatic scheduling adjustments during traditional cultural events.

YUWEI’s solution has helped over 20 Canadian mining companiesdigitize their fleet management systems, with an average ROI period of 14 months. With ongoing tech updates and localized support, YUWEI remains a trusted long-term partnerfor mining operations across Canada.

Email:hello@yuweitek.com