Collision Warning System in Mines

Collision Warning System in Mines

In mining operations, mine trucks serve as core transportation equipment, and their operational safety and management efficiency directly affect the overall benefits of mining production. However, complex terrain, harsh operating conditions, diverse vehicle types, and massive operational data pose numerous severe challenges to mine truck management. To address these issues, enterprises such as STONKAM and YUWEI have launched intelligent monitoring and management systems integrated with advanced technologies. Through comprehensive perception, intelligent analysis, and integrated management and control, these systems achieve upgraded safety and optimized efficiency in mine transportation.

Core Challenges in Mine Truck Management

1. Prominent Safety Risks: Unsafe behaviors such as driver fatigue and distracted operation occur frequently. Coupled with blind spots caused by mining terrain and the risk of long braking distances, collision accidents are prone to happen. Severe environments like dust and low visibility further exacerbate potential hazards.

2. Difficulties in Positioning and Communication: Signal obstruction in mountainous areas and mining pits weakens GPS/Beidou signals. Multipath interference in open-pit mines leads to positioning errors. Underground mines lack satellite signals and have limited 4G/5G coverage, which impairs data transmission and real-time monitoring.

3. Diversified Management Requirements: Mining fleets consist of various vehicle types including haul trucks and excavators, each with distinct monitoring priorities, making it difficult to integrate multi-source data.

4. Bottlenecks in Dispatching and Efficiency: Massive vehicle data overwhelms traditional cloud computing capabilities, resulting in delayed dispatching instructions. Emergency responses are not timely under dynamic road conditions, and an empty running rate of 30%–50% restricts operational efficiency.

5. Coexistence of Cost and Safety Risks: Harsh environments accelerate equipment aging, leading to high maintenance costs. Sensitive data faces leakage risks, and GPS spoofing may trigger accidents. Excessive monitoring tends to arouse employee resistance, while false alarms reduce system credibility.

Functions of the Intelligent Monitoring and Management System

(I) Safety Protection: Comprehensive Risk Avoidance

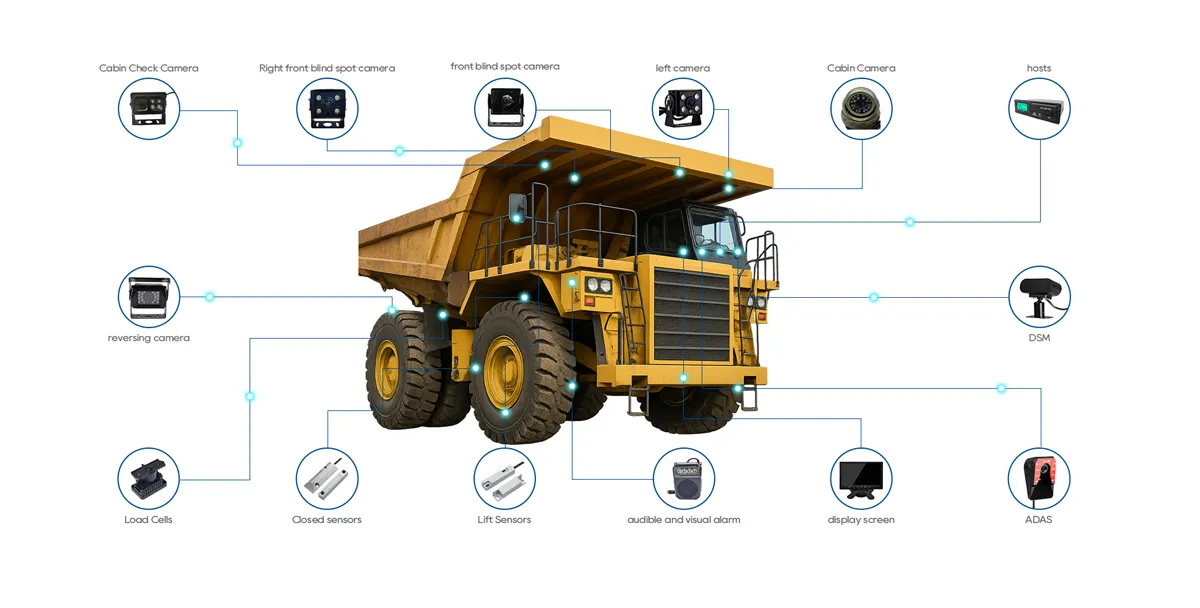

1. Driver Monitoring System (DMS): Equipped with in-vehicle infrared cameras and AI algorithms, it identifies high-risk behaviors such as driver fatigue, distraction, and mobile phone usage, triggering real-time voice alarms. Some systems also feature driver identification functions.

2. Blind Spot and Collision Protection

a. Forward Collision Warning (FCW): Fusion of radar and visual technologies monitors the distance and speed difference from the preceding vehicle, providing early warnings to reduce rear-end collision risks.

b. Blind Spot Detection (BSD): Side and rear cameras monitor targets in blind spots, issuing dual alerts via in-vehicle audio-visual alarms and external voice broadcasts.

c. Radar Obstacle Detection: All-weather millimeter-wave radars accurately detect personnel and obstacles in extreme environments.

d. 360° Panoramic Imaging: Stitches images around the vehicle to facilitate low-speed operations and eliminate visual blind spots.

3. Multi-dimensional Safety Alarms: Monitors speeding, sudden braking, equipment abnormalities, etc., triggering graded alarms. It supports event recording functions to capture video data of key scenarios, providing a basis for accident analysis.

(II) Intelligent Management: Optimizing Operational Efficiency

1. High-precision Positioning and Real-time Monitoring: Supports multi-mode positioning including GPS/Beidou/UWB, adaptable to various scenarios. 1080p high-definition cameras combined with night vision and wide-angle technologies enable 24/7 monitoring, allowing managers to remotely view real-time images and track playback.

2. Intelligent Dispatching and Path Optimization: AI algorithms realize intelligent task allocation and dynamic route adjustment, optimize path planning, and reduce empty running rates.

3. Data Integration and Analysis: Devices such as MDVR and T-box centrally store data and upload it to cloud platforms, providing multi-dimensional analysis of transportation volume, energy consumption, etc., and generating reports to support decision-making.

4. Equipment and Maintenance Management: Records vehicle file information, monitors equipment status in real-time, reduces fault downtime through predictive maintenance, and lowers maintenance costs.

(III) Stable and Reliable Operation

1. Interconnection Capability: Relying on 4G IoT technology, it realizes real-time communication between vehicle-mounted devices and cloud platforms, building a centralized fleet management ecosystem.

2. Environmentally Adaptive Design: Hardware features explosion-proof and dust-proof properties, while software supports stable operation in multiple scenarios.

3. Data Security and Privacy Protection: Adopts data encryption and secure cloud storage, and supports customized privacy settings.

4. Flexible Expansion and Integration: Supports hardware and software expansion and upgrading, with open interfaces that can integrate with systems such as MES and EAM.

System Application and Deployment

(I) Deployment and Adaptation Scope

The system has been implemented in mining-developed regions including China, Australia, Canada, and Chile, with China's solutions leading in intelligentization. It is adaptable to multiple scenarios such as open-pit mines and underground mines, covers fleets ranging from 10 to over 100 vehicles, and is compatible with various mining vehicles.

The intelligent mine truck monitoring and management system, deeply integrated with technologies such as AI and the Internet of Things, builds an integrated solution of "safety protection + intelligent management" to address the core pain points of mine transportation. From standardizing driver behaviors to optimizing intelligent dispatching, it realizes the visual, digital, and intelligent transformation of mine transportation. In the future, it will continue to drive the development of mining production towards a safer, more efficient, and more economical direction.