The Best Garbage Truck Camera System

Best Garbage Truck Camera System

Garbage truck fleet management has never been easier. YUWEI's Garbage Truck camera system continuously monitors drivers and their surroundings to ensure the safe operation of vehicles. It also allows fleet managers to have real-time access to the fleet's GPS location and live monitoring of both the interior and exterior scenes of the vehicles, making Garbage truck tracking management more convenient and secure.

Benefits of the Garbage Truck camera system:

1.Safety:

Envelop assets in a 360° camera coverage, monitoring the vehicle and driver environment in real-time.

2.Equipment Status:

Get real-time insights into the complete status of garbage truck hoppers, compactors, and auxiliary equipment.

3.Convenient Dispatch:

Record and track your fleets working hours and exact locations for efficient dispatching.

4.Engine Diagnostics:

Understand the engines health through real-time capture of key utilization metrics.

5.Custom Solutions:

YUWEI customizes Garbage truck management solutions according to your business needs.

Hardware configuration of the Garbage truck camera system:

1.AI Dashcam:

GPS-integrated integrated dashcam providing real-time recording for fleet driving.

hnweb_

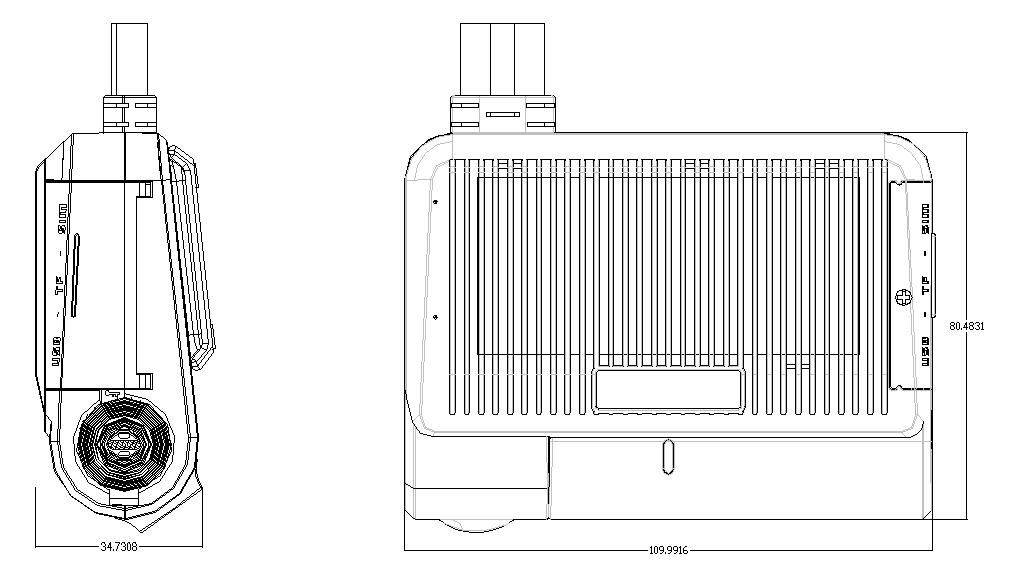

2.Mobile DVR:

1080p real-time recording for tracking and monitoring.

3.ADAS+DSM Advanced Driver Assistance System:

Monitor your drivers behavior, supervise against violations such as drunk or fatigued driving.

4.360° Onboard Camera:

Cameras offering a 360° coverage of the truck and equipment.

5.Rearview Camera and Radar:

Providing 360° protection for the garbage truck.

With the AI onboard camera of the Garbage truck management camera system from YUWEI, you can record at any time. Through our user-friendly interface, you can identify timestamps and/or addresses and request vehicle events. These events include videos that can help you understand what actually happened and provide irrefutable video evidence.

Benefits of installing YUWEI Garbage truck camera system:

1.Monitor Driver Behavior:

The third eye allows you to see all of the drivers actions in real-time, accurately understanding performance in terms of speed, compliance with traffic control devices, hard parking, etc.

2.Garbage Truck Body and Chassis Information:

Monitor real-time vehicle and body information. Prevent issues by checking hydraulic pressure, engine analysis, etc.

3.Complete Camera Coverage:

360° camera coverage provides comprehensive liability protection.

4.Real-time GPS Positioning:

Real-time uploading of the fleets GPS location information, allowing managers to know the current fleet position.

Installation Case of Garbage truck Camera System:

YUWEIs waste management camera tracking management system has been used by waste management trucks in more than 30 countries. Well-known brands include Dongfeng Motor Corporation, FAW Group, China National Heavy Duty Truck Group, Beiqi Foton Motor Co., Ltd., and JAC Motors.

If your citys waste management trucks need to install such camera systems, feel free to contact us! Email: hello@Yuweitek.com