Peru AI MDVR Protects Driver Safety & Fleet Management

Peru AI Vehicle MDVR

Mining is the backbone of Peru’s economy, contributing over 10% of the nation’s GDP. In gold mining operations, heavy dump trucks roar back and forth, buses shuttle workers across rugged terrain, and hidden risks lurk in every turn of the wheel. Each rotation is tied directly to both life and productivity. This is where YUWEI Technologysteps in—leveraging the latest AI-driven MDVR system to deliver smarter and safer fleet management.

For Peru’s largest gold mining enterprise, traditional fleet management methods are no longer sufficient to address increasingly complex safety challenges: driver fatigue, delayed reactions to sudden road hazards, and frequent blind spot accidents have become the “Sword of Damocles” hanging over mining operations. What they urgently need is an intelligent solution capable of cutting through harsh environments and delivering all-scenario safety protection.

At the core of this upgrade is the YUWEI F6. More than a simple recorder, it is a 4G-enabled MDVRthat integrates HD video recording, active safety features, and intelligent fleet management. Through its Driver Monitoring System (DMS), it can detect signs of fatigue or distraction, immediately alert the driver, and notify the fleet management team.

(I) Dual-Camera Panoramic Monitoring

The F6 adopts an integrated dual-camera design, building a 360° safety shield with both internal and external perspectives:

1. Front Starlight Wide Dynamic Camera(106° horizontal / 139° diagonal, 1080P HD): Ensures clear capture of road conditions regardless of harsh light shifts, sandstorms, or heavy rain.

2. Built-in IR-CUT Infrared Cabin Camera(152° horizontal / 180° diagonal, 720P HD): Equipped with 2MP infrared sensing, it continuously monitors driver status to prevent fatigue driving, phone use, and other unsafe behaviors.

3. Blind Spot Coverage: Optional AHD cameras (rear cargo, blind zone, vehicle rear) combined with BSD blind spot monitoring allow drivers to maintain full awareness of surrounding dynamics, eliminating the “blind spots” of traditional mining trucks.

(II) Active Safety Algorithms

The true value of the F6 lies in its built-in active safety algorithms, enabling precise detection of dangerous driving and real-time intervention:

1. ADAS (Advanced Driver Assistance System): Integrates Lane Departure Warning (LDW), Headway Monitoring & Warning (HMW), Forward Collision Warning (FCW), and Pedestrian Collision Warning (PCW). When the vehicle drifts, follows too closely, or faces sudden obstacles, the system issues real-time voice alerts(e.g., “Caution: Risk of forward collision”), preventing accidents before they occur.

2. DMS (Driver Monitoring System): Using facial recognition, it detects dangerous behaviors such as eye closure over 2 seconds, excessive yawning, or phone use. The system instantly triggers audiovisual alarms and pushes event data to the fleet platform.

3. Aggressive Driving Detection: Identifies harsh acceleration, sudden braking, and sharp turns common in mining, automatically logging data and generating reports to guide targeted driver training, reducing both vehicle wear and accident rates.

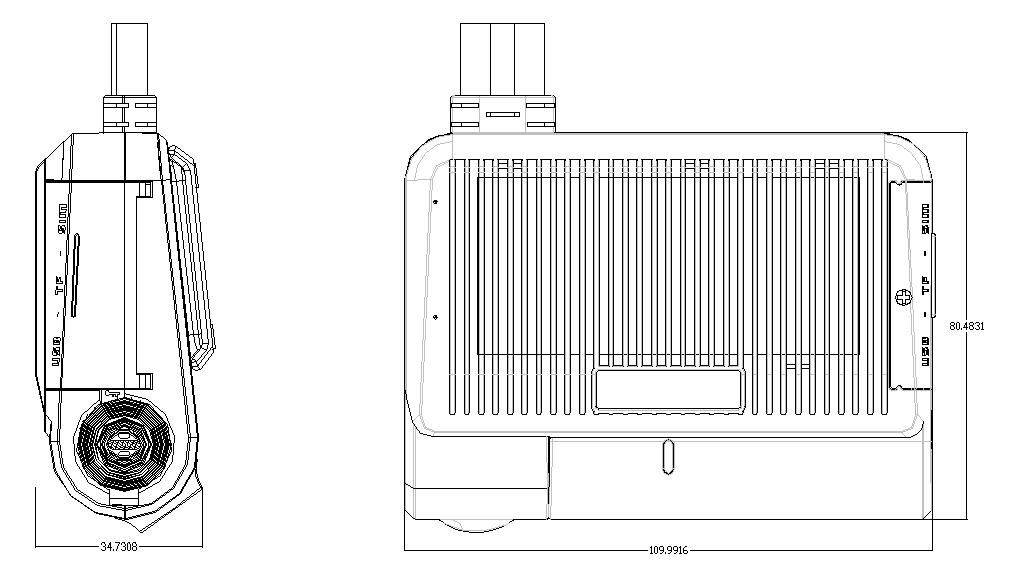

(III) Industrial-Grade Design

Considering Peru’s mining environments with constant vibration, power fluctuations, and dust intrusion, the F6 is engineered with full-spectrum durability:

1. Hardware Protection: Compact form factor avoids obstructing driver visibility, reinforced interfaces and anti-vibration housing withstand continuous mining shocks.

2. Low-Power Mode: Supports ultra-low standby (2mA/5mA), enabling ongoing monitoring (e.g., intrusion detection) even when the vehicle is off, with instant wake-up response.

3. Multi-Module Connectivity: Built-in 4G (LTE-FDD/TDD, WCDMA, GSM), Wi-Fi, and GNSS modules ensure reliable communication and real-time location tracking even in remote mining sites.

4. Extended Storage: Dual TF card slots (up to 2TB each), combined with patented DXR Stream storage format, guarantee secure video archiving without data loss due to storage failure.

The F6 is purpose-built for extreme mining conditions—tested to resist continuous vibration, power outages, and heavy-duty use—ensuring both stable operation and secure monitoring. YUWEI’s intelligent fleet solution is helping to redefine mining safety, starting in Peru and expanding to wherever safety comes first.

Would you like me to also polish this into a marketing brochure style(with catchy taglines, shorter sentences, and more emphasis on benefits), or keep it as a technical white paper stylefor professional presentation?

Email:hello@yuweitek.com