Farm Machinery Fleet Video Surveillance Solution

Industry Overview:

With the growth of the global population and technological development, agricultural production safety has gained increasing attention. However, existing agricultural loading equipment primarily relies on scheduled maintenance or regular servicing. During agricultural operations, the lack of real-time video surveillance makes it difficult to detect failures promptly and provide technical support, affecting the efficiency and quality of agricultural work. As a result, management teams are increasingly facing this issue.

Pain Point Analysis:

- Frequent Mechanical Failures:

Agricultural machinery is diverse, and the operational process is long. Due to inadequate supervision, irregular use of machinery often leads to slow or stagnant operations, or even equipment damage.

- Low Operational Efficiency:

Agricultural machinery has a low level of intelligence, preventing remote monitoring and intelligent management. The lack of unified management and coordination leads to inefficiency, especially during busy farming seasons when delays in land reclamation, transplanting, or harvesting affect agricultural income.

- Instability of Operators:

The operators of agricultural machinery are unstable, and their driving skills vary. Supervision is difficult, and some operators lack proper licenses or qualifications. There is a need to verify and record the legitimacy of operators, ensuring that only qualified personnel are allowed to drive the machinery.

- Real-time Monitoring Requirement:

Real-time monitoring of agricultural machinery is necessary, including location, speed, cargo hold sealing, operation time, and detection of any omissions.

- How to Implement Detailed Management:

How to use big data from IT systems to solve the farm management team’s challenges in standardized operations such as land reclamation, planting, harvesting, and spraying, and provide data support for the management team.

YUWEI Farm Machinery Fleet System

By installing 4G wireless video intelligent vehicle-mounted terminal kits on agricultural machinery, the solution enables high-precision vehicle positioning, real-time audio and video scheduling, cargo hold sealing detection, real-time fuel collection, RFID electronic tags, blind-spot radar detection and warning, and integrates backend data monitoring cloud platforms for agricultural machinery safety and operational management.

Farm Machinery Fleet System Features

- Comprehensive Monitoring:

Real-time video monitoring of vehicles, enabling remote viewing of on-site conditions and historical video data. When the vehicle turns left or right, the corresponding video screen can dynamically switch, providing driving assistance to the driver. Through GPS high-precision positioning, the system can monitor the vehicle’s location and status in real-time. If the vehicle exceeds the preset operation route, the system will alert the driver. The historical trajectory of the vehicle can also be retrieved.

- Refined Fuel Management:

The system transparently displays the entire fuel consumption process, alerts for abnormal fuel consumption in real-time, prevents fuel theft, and outputs reports for fuel consumption data.

- Abnormal Lifting Status Monitoring:

By installing lifting sensors, the system can monitor the lifting status of the machinery in real-time. If the machinery operates outside the designated area or violates operational norms, the system will send an automatic alert to the backend platform, preventing illegal actions such as arbitrary dumping of waste materials.

- Cargo Hold Sealing Monitoring:

By installing cargo hold loading detection sensors on agricultural machinery, the system can monitor the sealing status of the cargo hold and detect the loading/unloading data. Any abnormality will trigger an immediate alarm, preventing omissions during operations.

- Safe Driving Assistance System:

Using the built-in safety module in the vehicle-mounted terminal, the system can monitor the driver’s driving status via the DSM system, such as detecting yawning, closing eyes, smoking, making phone calls, drinking water, and looking around. The system also includes a front-view driving assistance ADAS system, which can issue warnings for front collision (FCW), close distance warning (HMW), and lane departure warning (LDW).

- Vehicle Operation Status Detection:

The vehicle terminal’s unique GSensor algorithm allows dynamic monitoring of vehicle operation, such as sudden acceleration, sudden deceleration, sharp turns, rollover collision detection, and alarm.

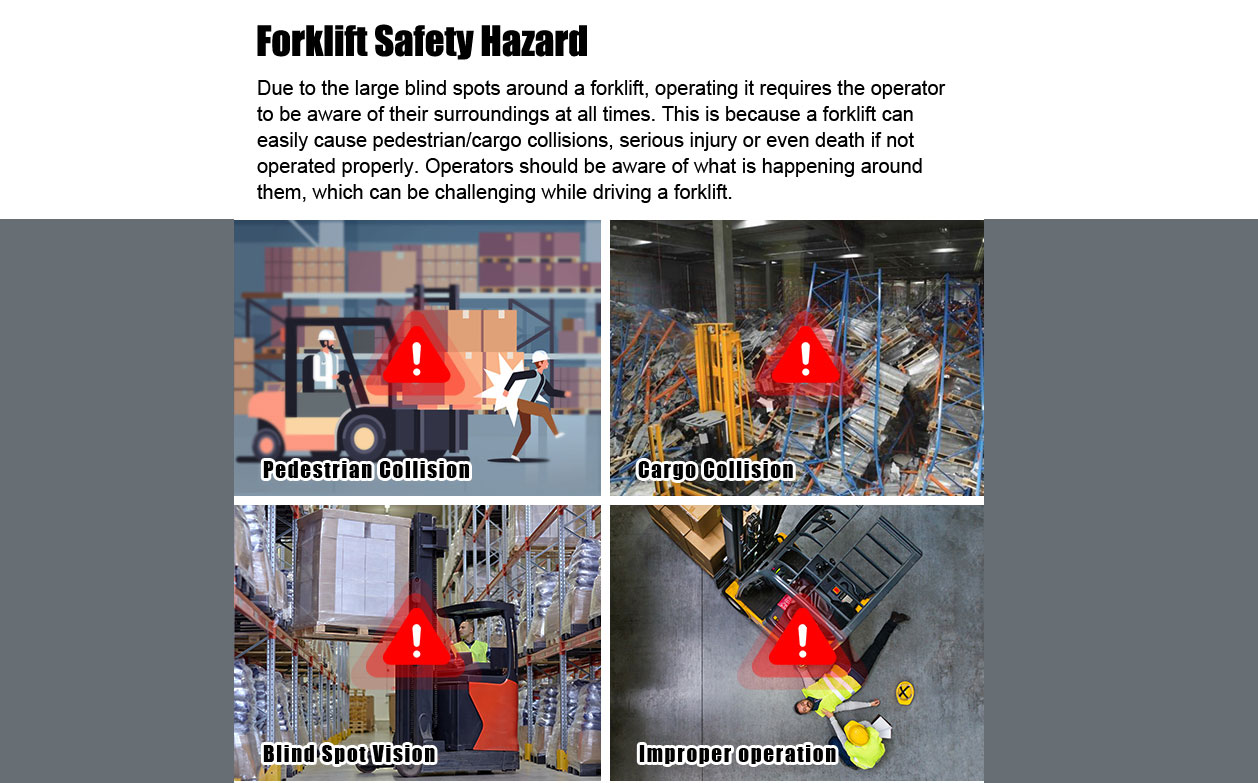

- Blind Spot Detection:

High-precision radar sensors can be installed on the right and rear sides of the vehicle to detect blind spots, reducing the likelihood of traffic accidents.

- Dump Truck Identity Recognition:

Dump trucks are equipped with anti-disassembly RFID electronic tags, recording relevant vehicle information (e.g., model, driver name, license plate, load capacity, and company). RFID readers (fixed or handheld) can be installed at monitoring locations, automatically recording and transmitting information such as arrival or departure time to the backend system.

- Data Statistics:

Attendance reports, operational reports, and alarm reports.

- Information Management:

Management of basic information, vehicle maintenance data, and maintenance records.

Email:hello@yuweitek.com