GPS Monitoring System for Heavy Equipment

Heavy Equipment GPS Monitoring System

As the global construction, mining, and logistics industries continue to thrive, managing fleets of heavy equipment has become more challenging than ever. How can companies monitor these valuable assets in real-time? How can equipment utilization be optimized? How can operational costs be reduced? YUWEI, a Chinese technology company, has developed a smart solution: a GPS monitoring system specifically designed for heavy equipment. This article explores how YUWEI’s system leverages advanced technology to help enterprises manage all types of heavy machinery and achieve digital transformation in fleet operations.

Core Functions of the Heavy Equipment GPS Monitoring System

YUWEI’s GPS monitoring system is purpose-built for heavy-duty fleets and offers the following core features:

1. Real-Time Location Tracking

Utilizing high-precision GPS/BeiDou dual-mode positioning with an error margin of less than 5 meters, the system can accurately display the real-time locations of excavators, cranes, concrete pump trucks, and other heavy equipment.

2. Equipment Status Monitoring

The system monitors critical parameters such as engine status, fuel consumption, and hydraulic pressure, making it suitable for a wide range of construction machinery and transport vehicles.

3. Geo-Fence Alerts

Virtual boundaries can be set for valuable equipment like mining trucks and bulldozers. Any breach of these boundaries triggers instant alerts.

4. Maintenance Management

Automatically generates maintenance schedules based on machine operating hours—ideal for road construction equipment like asphalt pavers and rollers that require regular servicing.

5. Data Analysis Reports

Provides multi-dimensional analytics on equipment utilization, idle time, and operational efficiency to help optimize fleet deployment.

Monitoring Solutions for All Types of Heavy Equipment

YUWEI’s system can be widely applied to the following categories of heavy equipment:

Construction Machinery

1. Hydraulic Excavators (large, medium, small)

2. Wheel/Crawler Loaders

3. Bulldozers (wetland and standard models)

4. Motor Graders (self-propelled and towed)

5. Road Rollers (single drum, double drum, pneumatic tire)

Lifting and Transport Equipment

1. Truck Cranes (25-ton to 500-ton class)

2. All-Terrain Cranes

3. Tower Cranes (luffing jib, flat-top)

4. Truck-Mounted Cranes (straight boom, knuckle boom)

5. Heavy-Duty Flatbed Transporters

Road Construction Machinery

1. Asphalt Concrete Pavers

2. Soil Stabilizers

3. Milling Machines (cold and hot types)

4. Concrete Pump Trucks (boom and trailer types)

5. Sprayers (asphalt, emulsified asphalt)

Mining Equipment

1. Mining Dump Trucks (rigid and articulated)

2. Underground Loaders

3. Drilling Rigs (surface and underground)

4. Crushing and Screening Equipment

5. Large-Scale Mining Excavators

YUWEI System’s Technical Advantages

1. Anti-Interference Design

Engineered for harsh industrial environments, the system maintains stable signals even in metal-shielded areas—ideal for steel plants and mining sites.

2. Multi-Sensor Integration

In addition to the GPS module, the system includes vibration, tilt, and temperature sensors for comprehensive equipment monitoring.

3. Low Power Consumption

Industrial-grade chipsets ensure stable operation even in extreme temperatures (-40°C to 85°C).

4. Modular Architecture

Flexible module configuration based on equipment type—for example, prioritizing hydraulic system monitoring for concrete pump trucks and load data for mining trucks.

5. Dual Communication Modes

Supports both 4G/5G networks and satellite communication, ensuring real-time connectivity even in remote mining areas.

Practical Features for Fleet Managers

To meet the unique needs of heavy equipment fleet managers, YUWEI offers a suite of practical tools:

1.Driver Behavior Analysis

Monitors harsh acceleration and braking to reduce wear and tear.

2.Fuel Theft Detection

Uses flow meters to identify abnormal fuel consumption.

3.Operational Efficiency Metrics

Tracks KPIs such as excavator loading cycle times.

4.Multi-Level Access Control

Differentiated viewing permissions for management, site supervisors, and maintenance staff.

5.OBD-II Interface Integration

Reads diagnostic trouble codes to provide early warnings of potential issues.

Fleet Management Tracking Devices

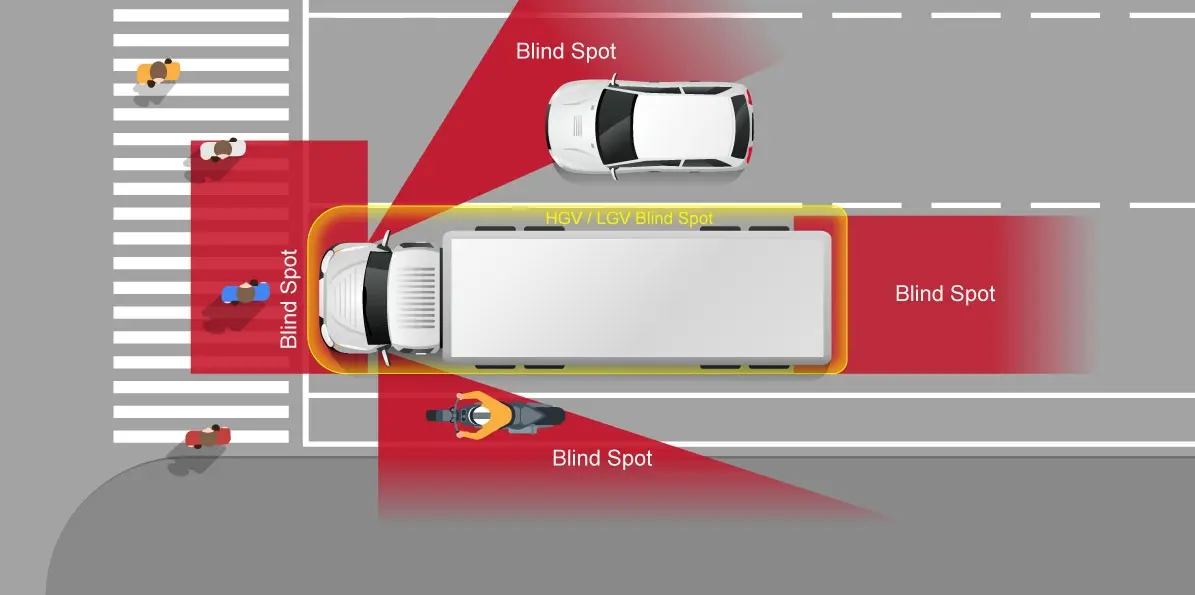

1. AI Dash Cam

2. AI MDVR

5. GPS Tracker

6. Vehicle Sensors

7. ADAS Camera

8. DMS Camera

9. 360° Reversing System

10. Waterproof Reversing Camera

12. Alarms, and more

Success Stories: Trusted by Global Heavy Equipment Enterprises

YUWEI’s GPS monitoring system has been successfully implemented in various international projects:

1. A Major Mining Group in Australia

Deployed across 78 mining trucks and 12 electric shovels, resulting in a 23% increase in equipment utilization and an annual maintenance cost saving of approximately USD 2 million.

2. A Construction Company in Kuwait

Managed over 200 pieces of construction machinery, reducing project timelines by 15% through optimized dispatching.

3. A Road Construction Contractor in Africa

Monitored 56 road construction machines, cutting fuel consumption by 18% and reducing unplanned downtime by 40%.

With its advanced technological capabilities, YUWEI’s GPS monitoring system empowers businesses to efficiently manage heavy equipment fleets. Whether you're in construction, mining, or logistics, this system provides a comprehensive monitoring solution that ultimately leads to cost reduction and operational efficiency.

Email:hello@yuweitek.com