American Well Fleet Monitoring System

Well Fleet Monitoring System

As one of the world’s largest oil producers, the United States has over 1 million active oil wells, producing approximately 11 million barrels of crude oil per day. Behind this massive production scale lies a complex logistics and transportation network, in which oil tanker fleets play a crucial role. Statistics show that the U.S. oil industry operates over 200,000 specialized oil tankers, transporting billions of barrels of crude and refined oil annually.

However, managing wellsite fleets presents numerous challenges: complex routes, high safety risks, difficulty monitoring efficiency, and stringent compliance requirements. These are exactly the areas where the professional well fleet monitoring systemdeveloped by China’s YUWEIoffers a perfect solution.

Current Situation & Pain Points of U.S. Wellsite Transportation

1. Management Challenges from Wide Geographic Distribution

Oil wells in the U.S. are widely distributed, from the Permian Basin in Texas to the Bakken region in North Dakota, and the North Slope in Alaska. Tankers often travel hundreds of miles. According to the U.S. Energy Information Administration (EIA):

a. Texas: Over 300,000 active wells

b. North Dakota: About 15,000 active wells

c. New Mexico: About 60,000 active wells

Such dispersed production bases make fleet management extremely complex. Traditional manual dispatch methods can no longer meet the needs of modern oilfield transportation.

2. Safety and Compliance Pressures

Oil tanker transport is a high-risk industry, with strict regulations from the U.S. Department of Transportation (DOT):

a. Driver Hours of Service (HOS) must be recorded

b. Vehicles require regular DVIR inspections

c. Hazardous materials must be monitored throughout transit

Violations can result in hefty fines or operational shutdowns. In 2022, fines in the U.S. oil tanker sector exceeded $23 milliondue to non-compliance.

3. Rising Operational Costs

With fluctuating oil prices and increasing labor costs, transportation profit margins are under pressure:

a. Diesel prices have risen approximately 45% compared to five years ago

b. The average annual driver salary has reached $65,000, amid a severe driver shortage

c. High empty return rates (up to 30% for some fleets) cause massive waste

Core Advantages of the YUWEI Well Fleet Monitoring System

To address these unique challenges in the U.S. oilfield industry, YUWEIhas developed an intelligent monitoring solution tailored specifically to oil tanker fleets, offering the following key advantages:

1. Real-Time Location Tracking and Smart Dispatch

a. Meter-level GPS accuracy: Real-time tracking of every vehicle

b. Oilfield-specific map integration: Includes road networks of major U.S. oilfields

c. AI-powered smart dispatch: Optimizes routes based on production output, road conditions, and vehicle status

Case Study: After adopting the YUWEI system, a mid-sized Chinese oil transport company saw a 22% reduction in average delivery time and a drop in empty load rate from 28% to 15%.

2. Comprehensive Safety Monitoring

a. Tank monitoring: Real-time data on temperature, pressure, and liquid level

b. Driver Monitoring System (DMS): Alerts for fatigue driving, hard braking, and other risky behaviors

c. ADAS: Advanced driver assistance system

d. Geofencing: Automatic alerts for sensitive or restricted areas

Compliance Assurance: The system auto-generates DOT-compliant reports, ensuring full FMCSA regulatory adherence.

3. Advanced Predictive Maintenance

a. Vehicle health diagnostics: In-depth analysis via OBD-II data

b. Maintenance reminders: Based on actual usage, not fixed intervals

c. Fault prediction: Identifies potential issues early to reduce breakdowns

Impact: Fleets using YUWEI have seen a 35% reduction in unplanned maintenance downtime.

Why U.S. Oilfield Companies Choose China’s YUWEI

1. Industry-Specific Design

Unlike generic fleet management systems, YUWEI is purpose-built for oil tanker operations:

a. Explosion-proof design: Meets ATEX standards

b. Corrosion-resistant housing: Suitable for harsh oilfield environments

c. Compatiblewith major U.S. tanker brands like Kenworthand Peterbilt

2. Significant Cost Advantage

Compared to domestic U.S. solutions, YUWEI offers:

a. 30–40% lower hardware cost

b. 50% lower software subscription fees

c. 24/7 Chinese-language technical support, with optional English service

3. Extensive Industry Experience

YUWEI has served over 500 oil companiesworldwide, including:

a. Designated supplier for China’s three major oil companies

b. Partner to multiple national oil companies in the Middle East

c. Technology provider to leading oil transport companies in Latin America

Technical Specifications and Deployment Plan

Hardware Components

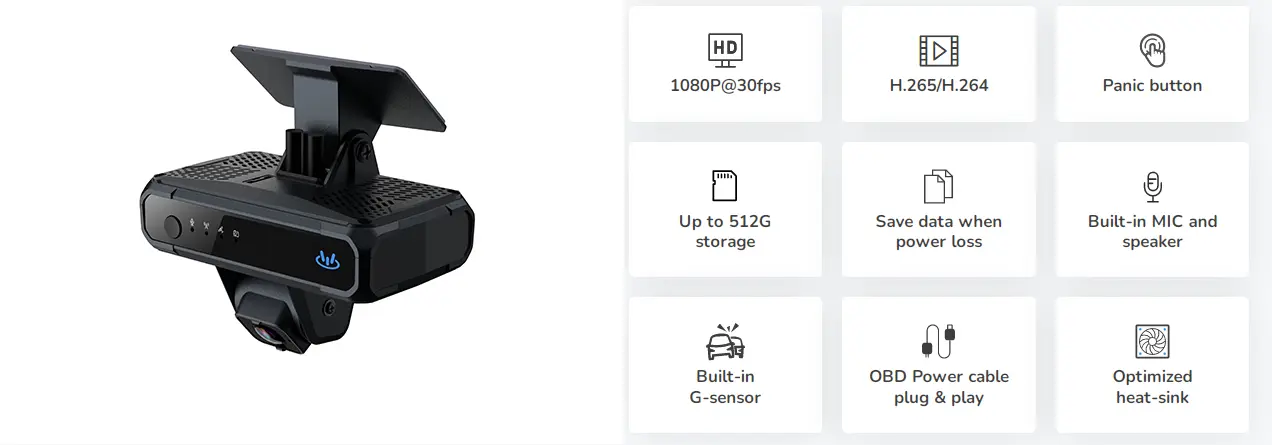

1. AI Dash Cam

2. AI MDVR

5. GPS Tracker

6. Vehicle Sensors

7. ADAS Camera

8. DMS Camera

9. 360° Reversing System

10. Waterproof Reversing Camera

12. Alarms, and more

Software Platform

1. Cloud-Based Architecture: Options include Alibaba Cloud or U.S.-based services such as AWS, with local data storage

2. User Interface: Supports English and Spanish, tailored for American users

3. API Integration: Compatible with mainstream ERP systems (SAP, Oracle, etc.)

Deployment Process

1. Needs analysis and customization (1–2 weeks)

2. Hardware installation and debugging (~2 hours per vehicle)

3. System training (1–3 days)

4. Continuous optimization (ongoing check-ins)

Frequently Asked Questions (FAQ)

Q: Does a China-made system meet U.S. standards?

A: Yes, the YUWEI system is FCC-certified for the U.S. market.

Q: How is data security ensured?

A: All data can be stored on U.S.-based AWS servers with AES-256 encryption, fully compliant with GDPRand CCPA.

Q: Can existing fleets be retrofitted gradually?

A: Yes. Phased deployment is supported, allowing the old and new systems to operate concurrently for a smooth transition.

Q: What is the response time for technical support?

A: YUWEI has a U.S.-based support center offering 24/7 service, with an average response time of under 30 minutes.

Conclusion: The Smart Choice to Boost U.S. Wellsite Transport Efficiency

As the U.S. oil industry faces increasing efficiency bottlenecks and safety challenges, YUWEI’s Well Fleet Monitoring Systemprovides a proven solution. With its industry-specific design, excellent cost-performance ratio, and reliable technical support, it is becoming the preferred choice for more and more American oil companies.

Email:hello@yuweitek.com